Manhole Step Is Durable

Urban infrastructure relies on safe, durable access points for maintenance of stormwater and sewer systems. Central to this are galvanized step irons, manhole step installations, and innovative plastic manhole steps. These components ensure worker safety, regulatory compliance, and long-term functionality in challenging environments. This article explores their engineering, applications, and evolving standards, addressing key industry needs from corrosion resistance to ergonomic design.

Galvanized step irons provide unmatched corrosion resistance in harsh environments

The relentless assault of moisture, hydrogen sulfide gas, acidic effluents, and varying pH levels within sewer systems creates an exceptionally corrosive environment. Traditional unprotected steel components rapidly deteriorate, posing significant safety risks and necessitating frequent, costly replacements. galvanized step irons are engineered to combat this degradation. The galvanization process involves coating high-tensile strength steel in a layer of molten zinc. This zinc coating acts sacrificially; when the surface is compromised, the zinc corrodes first, protecting the underlying steel substrate (cathodic protection).

The effectiveness of galvanized step irons extends beyond general atmospheric corrosion. They demonstrate remarkable resilience against:

- Chemical Attack: Resisting corrosion from acids, alkalis, and organic compounds commonly found in sewage.

- Abrasion: The zinc coating is durable enough to withstand the wear and tear of boots, tools, and debris during routine access.

- Galvanic Corrosion: Properly specified and installed galvanized steel is less susceptible to galvanic corrosion when in contact with common manhole materials like concrete compared to dissimilar metals.

Step irons are an essential part of storm water and sewer drainage systems. Made from high-strength steel encapsulated in robust hi-vis polypropylene plastic, they are included in the infrastructure consumables.

A manhole step configuration requires precise engineering for optimal safety

The manhole step is not merely a foothold; it is a critical engineered safety component within a confined space entry system. Its design, placement, and installation directly impact the safety and efficiency of personnel descending into and ascending from often deep, dark, and potentially hazardous shafts. Optimal manhole step configuration adheres to rigorous principles:

- Load Capacity: Steps must withstand significant dynamic loads.Account for the weight of a worker plus tools, potential impacts, and safety factors. Engineering calculations consider material yield strength, embedment depth, and concrete strength.

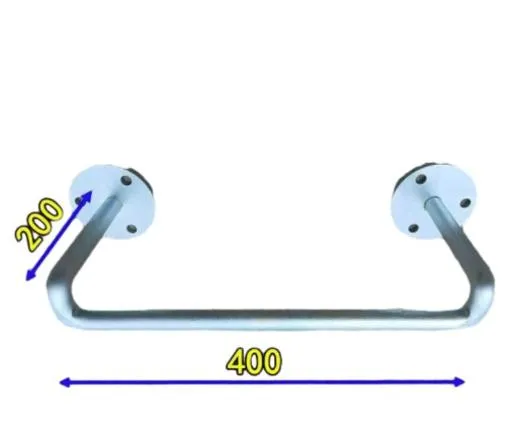

- Ergonomics and Spacing: Step placement is critical for safe climbing. Vertical spacing must allow for natural climbing rhythm without excessive stretching or cramped movements. Lateral positioning should ensure a stable posture and clear path, avoiding obstructions like pipes or cables. The step tread design (width, depth, contour) must accommodate boot soles securely.

- Embedment and Fixing: The strength of the step itself is irrelevant if its anchorage fails. Steps are embedded deep into the manhole wall (concrete or brick) during construction or retrofitted using high-strength chemical anchors or mechanical expansion bolts. The embedment method must transfer the applied loads effectively into the surrounding structure, resisting pull-out, shear, and torsion forces. Depth, anchor type, and concrete quality are paramount.

- Clearance and Obstruction: Steps must be positioned to provide adequate clearance from the manhole opening/cover and any internal obstructions (pipes, valves, ladders) to prevent tripping, snagging, or restricted movement during entry/egress. This requires careful planning during the manhole design or rehabilitation phase.

- Compatibility: The step system must be compatible with the manhole material (concrete, brick, polymer) and the expected environmental conditions (corrosion potential). The fixing method must be suitable for the substrate.

Failure in any of these aspects can lead to slips, falls, entrapment, or structural collapse – incidents with potentially severe or fatal consequences. Therefore, specifying and installing a compliant, well-engineered manhole step system is non-negotiable for responsible infrastructure management.

Plastic manhole steps revolutionize maintenance with polymer innovation

Injection-molded from glass-reinforced nylon or polypropylene, plastic steps eliminate electrolytic corrosion in reinforced concrete. Key breakthroughs include:

Safety Yellow pigmentation enhancing visibility in low-light shafts

Non-slip diamond tread patterns

Dielectric properties preventing electrical accidents

Our plastic encapsulated step irons are manufactured to suit stormwater and sewer applications in accordance with European Standards, in Safety Yellow color. Our plastic step irons also have a non-slip surface on the tread area to meet requirements.

Galvanized step irons outperform plastics in high-temperature scenarios

High-Temperature Stability: Engineering polymers have defined maximum continuous service temperatures.Exceeding these limits can lead to softening, creep (permanent deformation under load), or reduced strength. Galvanised step irons, being metal, maintain their structural integrity and load-bearing capacity at much higher temperatures.This makes them the preferred or mandatory choice in applications like:

- Steam tunnels and district heating systems.

- Manholes near industrial exhaust vents or combustion sources.

- Locations with high fire risk where material flammability is a concern (galvanized steel has better inherent fire resistance than most plastics).

FAQS about Regarding plastic manhole steps and galvanized alternatives

What are the primary advantages of plastic manhole steps over galvanized steel?

The core advantages of plastic manhole steps (specifically steel-core encapsulated) lie in their exceptional corrosion and chemical resistance, making them ideal for harsh sewer environments with high levels. Their integral Safety Yellow color provides superior visibility in dark shafts, and the molded non-slip tread surface enhances safety. They are also electrically insulating and lighter weight for easier installation. They eliminate the risk of electrolytic corrosion in concrete.

How do galvanized step irons prevent failure in saltwater applications?

The zinc layer sacrifices itself electrolytically, protecting underlying steel. ASTM B117 salt-spray tests confirm 1,000+ hours without red rust. Additional chromate sealing enhances longevity in marine outfalls.

How does the load capacity compare between plastic manhole steps and galvanized step irons?

Both high-quality plastic manhole steps (with steel cores) and galvanized step irons are engineered and tested to meet or exceed international safety standards for load capacity. The critical factor is not the base material alone, but the overall design, core strength (for plastic), anchorage system, and compliance certification. Reputable manufacturers provide certified load ratings for their specific products. Both types are capable of meeting the rigorous demands for worker safety when properly specified and installed.

Why choose galvanized step irons for high-voltage utility tunnels?

Galvanization creates conductive paths, preventing static buildup. Copper-bonded grounding lugs can be welded directly to steps, achieving <5 ohm resistance for arc-flash safety.

Can plastic manhole steps be retrofitted into existing concrete manholes?

Yes, plastic manhole steps are excellent candidates for retrofitting. Their lightweight nature simplifies handling within the confined space. They are typically installed using high-strength, corrosion-resistant chemical anchors (epoxy resin systems) or specialized mechanical anchors designed for concrete and compatible with the polymer encapsulation. The retrofit process involves drilling holes to the specified depth and diameter, cleaning the holes meticulously, injecting adhesive (for chemical anchors) or setting the mechanical anchor, and then inserting and securing the step. Proper hole preparation and adhesive cure time are critical for achieving the required pull-out strength.

By understanding the distinct advantages, limitations, and engineering principles behind these components, specifiers, contractors, and utility managers can make informed decisions that prioritize worker safety, ensure regulatory compliance, maximize the longevity of assets, and ultimately contribute to the reliable functioning of our vital water and wastewater systems. Investing in high-quality, standards-compliant access solutions is not merely a procurement decision; it is an investment in human safety and the resilience of the urban environment itself. The continuous innovation in materials and design promises even safer and more durable access solutions for the infrastructure challenges of tomorrow.

-

Square Sewer Cover Enhances Urban SafetyBalitaAug.01,2025

-

Pipe Fitting Requires Precise AlignmentBalitaAug.01,2025

-

Manhole Cover Is Found WorldwideBalitaAug.01,2025

-

Hole Cover Frame On RoadsBalitaAug.01,2025

-

Gully Grate Improves Road SafetyBalitaAug.01,2025

-

Man Hole Cover Round Load CapacityBalitaJul.31,2025

-

Pipe Repair Clamp Underground Pipe SolutionsBalitaJul.31,2025