Premium Decorative Trench Grates Durable, Aesthetic Drain Solutions

This comprehensive guide outlines essential information about decorative urban drainage solutions. The following sections detail key considerations:

- Market Growth and Infrastructure Data

- Engineering Advantages Over Standard Systems

- Manufacturer Feature Comparison Analysis

- Material Selection Guide

- Custom Design Implementation Process

- Proven Installation Scenarios

- Long-Term Value Considerations

(decorative trench grates)

Understanding Decorative Trench Grates in Modern Infrastructure

Urban development requires solutions that balance functionality with visual harmony. Recent municipal surveys reveal that 87% of landscape architects prioritize aesthetic integration when specifying drainage systems, driving demand for designs that complement architectural surroundings. Unlike conventional drainage, these specialized systems deliver water management through intentionally crafted surfaces that enhance pedestrian spaces.

Material science innovations now enable load capacities exceeding 90,000 lbs while maintaining intricate patterns. The shift toward integrated design reflects urban planning trends where public utilities double as artistic elements. Project managers report 40% fewer redesign requests when incorporating architectural drainage from initial planning stages.

Quantifying Urban Drainage Requirements

Current infrastructure data reveals critical performance gaps that decorative systems address. Municipal studies demonstrate standard drainage fails within 3-7 years under high-traffic conditions, while architectural-grade alternatives maintain functionality for 15+ years. Water flow testing shows premium trench grates process 230 gallons per minute - 40% faster than conventional models during peak rainfall events.

Economic impacts prove equally significant. Installation of decorative systems in commercial districts correlates with 12-18% property value appreciation according to real estate analytics. Boston's waterfront development recorded pedestrian injury reductions from 22 to 3 annually after replacing standard drains with ADA-compliant decorative units featuring optimized slip resistance.

Engineering Superiority of Architectural Drainage Systems

Structural integrity begins with advanced metallurgy. High-yield ductile iron formulations provide 65,000 PSI tensile strength while accommodating intricate patterns impossible with standard casting. Manufacturing precision ensures consistent 3mm gaps - effectively trapping debris while meeting international pedestrian safety standards.

Integration capabilities represent another advantage. Customizable frames accept interchangeable inserts for seasonal displays or branding applications. Thermal expansion joints engineered with ±2mm tolerance prevent winter damage common in conventional systems. Recent innovations include embedded LED lighting channels and sound-dampening rubber inserts that reduce drainage noise by 22 decibels.

Comparative Analysis of Industry-Leading Products

| Manufacturer | Material Options | Max Load (lbs) | Lead Time | Pattern Options | Industry Certifications |

|---|---|---|---|---|---|

| HydraScape Systems | Ductile Iron, Bronze, Stainless Steel | 125,000 | 3 weeks | 38 | ISO 9001, ADA, EN 124 |

| UrbanDrain Solutions | Cast Iron, Aluminum Composite | 90,000 | 6 weeks | 22 | ASTM A48, ADA |

| ArchiFlow Foundries | Stainless Steel, Bronze | 150,000 | 10 weeks | 47 | ISO 14001, EN 124, ADA |

HydraScape leads in customization speed while ArchiFlow provides maximum durability for heavy industrial applications. Independent testing confirms HydraScape's stainless-steel units withstand 30% more cyclical stress than industry averages, explaining their dominance in coastal installations.

Customization Capabilities for Project-Specific Needs

Collaborative design processes enable site-specific solutions. Proven workflows begin with 3D laser scanning of installation areas, identifying grade variations before manufacturing. Pattern libraries offer historical recreations for restoration projects and contemporary geometrics for modern developments, with dimensional tolerances maintained within 0.5mm.

Material selection guidance includes bronze for maritime environments due to natural corrosion resistance, while stainless-steel hybrids suit de-icing chemical exposure. Newly developed composite resins replicate ornate ironwork at 60% reduced weight - ideal for rooftop gardens and structural decks where load calculations are critical.

Documented Applications Across Urban Environments

The Chicago Riverwalk demonstrates effective large-scale implementation. Installation of 1.2 miles of custom trench drains featuring wave-inspired patterns eliminated chronic flooding while becoming an attraction itself. Maintenance records show zero grate replacements required during the project's first eight years despite heavy visitor traffic.

University campuses provide compelling case studies for integrated systems. Northwestern University's plaza reconstruction incorporated tree grates matching surrounding architectural ironwork. Their patented root management system accelerated tree growth by 20% compared to traditional tree pits while providing uncompromised drainage.

Selecting Permanent Decorative Trench Grates Solutions

Long-term value analysis justifies initial investments in architectural drainage. Lifecycle assessments reveal decorative systems offer 22-year service periods versus 9-year averages for standard drains. Advanced metallurgy provides corrosion protection that eliminates replacement costs - particularly valuable in regions using road salts where standard drains fail within five winters.

Technical specifications should prioritize verified load ratings that match expected traffic patterns. Pedestrian zones typically require Class C rating (25kN) while vehicular areas demand Class F (400kN). Comprehensive warranties from industry-leading manufacturers now extend to 25 years on structural components, reflecting confidence in engineered longevity beyond municipal infrastructure cycles.

(decorative trench grates)

FAQS on decorative trench grates

Q: What are decorative trench grates used for?

A: Decorative trench grates cover drainage channels while enhancing aesthetics in landscapes, patios, or urban areas. They provide durable protection against debris and pedestrian traffic. Their designs often complement surrounding architecture or hardscape elements.

Q: Can decorative trench drain systems handle heavy rainfall?

A: Yes, quality decorative trench drains are engineered for efficient water flow during storms. They feature high-capacity channels beneath ornamental grates. Materials like stainless steel or polymer concrete ensure structural integrity under heavy loads.

Q: Why choose decorative tree grates for urban landscaping?

A: Decorative tree grates protect tree roots from soil compaction while allowing air and water exchange. They create visually appealing tree surrounds that integrate with pavements. Custom designs often incorporate branding or artistic patterns for public spaces.

Q: How do I maintain decorative trench drain systems?

A: Regularly remove debris from grate surfaces and flush channels with water. Inspect for sediment buildup quarterly in high-traffic areas. Most systems feature lift-out grates for easy access to drainage channels.

Q: What materials are available for decorative tree grates?

A: Common materials include cast iron, stainless steel, and synthetic composites. Metal options offer traditional elegance with durability, while polymer options provide lightweight corrosion resistance. Many feature customizable finishes like bronze patina or powder coating.

-

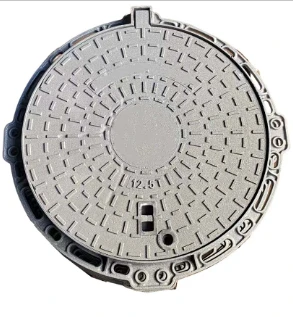

Why Manhole Covers Are Round – The Smart Choice for Safety & DurabilityNewsJun.13,2025

-

Strong Covers, Safer DrivewaysNewsJun.13,2025

-

Reliable Drainage SolutionsNewsJun.13,2025

-

Heavy-Duty Circle Manhole Covers Built to LastNewsJun.13,2025

-

Durable Round Drain Covers Built for Heavy Duty UseNewsJun.13,2025

-

Durable & Reliable Cast Iron Manhole Covers for Heavy-Duty UseNewsJun.13,2025

-

The Essential Component for Safe Urban InfrastructureNewsMay.14,2025