Stainless Steel Flanged Concentric Reducer & Saddle Clamp Solutions

for Modern Piping Applications

for Modern Piping Applications

HEBEI YONGQIAN TRADING CO.,LTD.

+8615130998744

+8615130998744

Room 1005, Building 1-2, Phase I, North China Golden Sun Commercial City, Xinhuanan Road, Xiangdu District, Xingtai City, Hebei Province, China

In the rapidly evolving world of industrial piping, the quest for premium, durable, and efficient solutions is relentless. Among the products transforming industry standards, the stainless steel flanged concentric reducer and the saddle clamp (including variants: saddle clamp 1 1 2, saddle clamp 1 2, saddle clamp 2 inch) stand out due to their reliability, technological advancement, and versatility in numerous sectors. This article explores market and technology trends, technical parameters, and practical applications of these essential fittings, with deep insight into selection, application, and industry best practices.

Industry Trends: Stainless Steel Flanged Concentric Reducers & Saddle Clamps

- The stainless steel flanged concentric reducer segment, fueled by the growth of petrochemical, water treatment, and HVAC industries, has witnessed robust expansion globally [Pipefittingnews, 2023].

- The increasing adoption of saddle clamps—especially saddle clamp 1 1 2, saddle clamp 1 2, and saddle clamp 2 inch—in pipeline support for PVC/PE, highlights the push for modularity, corrosion resistance, and ease of installation [ENG-TIPS Forum].

- Technological innovation focuses on enhancing pressure ratings, anti-corrosive coatings (e.g., blue epoxy resin), and efficient gasketing systems, responding to stricter environmental and longevity demands.

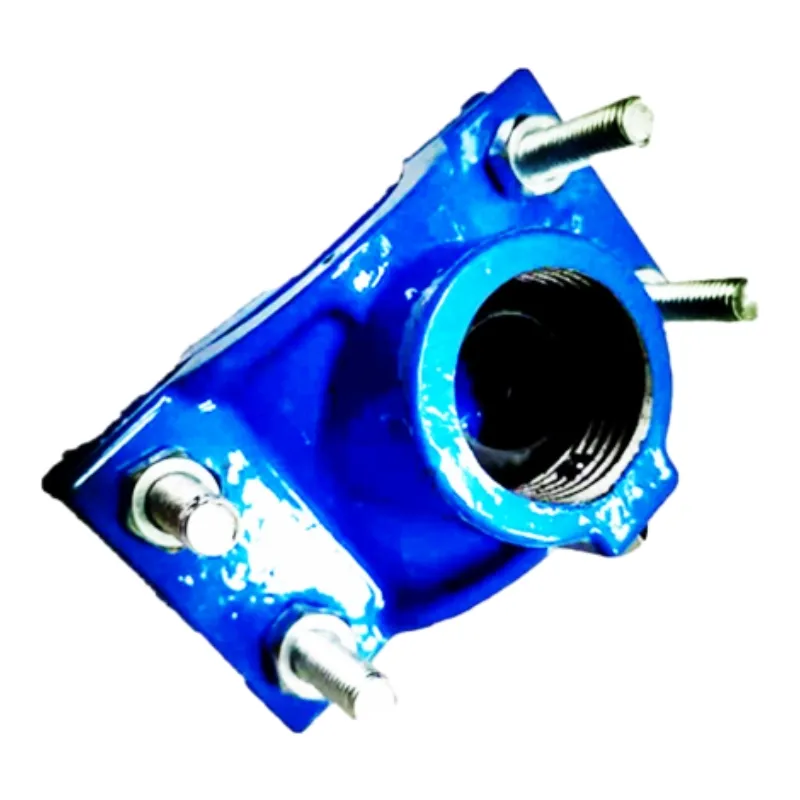

Comprehensive Product Introduction: Saddle Clamp For PVC/PE Pipe

Product Name: Saddle Clamp For PVC/PE Pipe

Product Description: Material: GGG50 | Pressure: PN16 | Coating: Blue epoxy resin painting

Gasket: EPDM Rubber Ring/Copper Ring/Steel Bolt and Nut

Product Page: Saddle Clamp For PVC/PE Pipe

Product Description: Material: GGG50 | Pressure: PN16 | Coating: Blue epoxy resin painting

Gasket: EPDM Rubber Ring/Copper Ring/Steel Bolt and Nut

Product Page: Saddle Clamp For PVC/PE Pipe

Technical Parameters Table: Stainless Steel Flanged Concentric Reducer

| Parameter | Standard Range | Typical Value | Notes |

|---|---|---|---|

| Material Grade | SS304, SS316, SS321 | SS316 | Corrosion resistance, food & pharma approved |

| Size Range (DN) | DN25–DN1200 | DN50–DN400 | Custom and standard available |

| Wall Thickness | 2mm–16mm | 3mm, 5mm | Project dependent |

| Flange Standard | ASME B16.5, DIN, EN1092-1 | ASME B16.5 | Regionally required |

| Pressure Rating | PN6–PN64 / 150–600LB | PN16 / 150LB | Tested for each production lot |

| Surface Finish | Pickled, Polished | Pickled | Anti-corrosion, hygienic applications |

| Temperature Range | -40°C to +500°C | -30°C to +400°C | Varies by material and medium |

ECharts Visualization: Concentric Reducer Technical Parameter Trends

Saddle Clamp Technical Data Visualization

Application Scenarios: Stainless Steel Flanged Concentric Reducer & Saddle Clamp Variants

- Water supply and treatment projects—ensuring smooth diameter transitions and no dead zones with stainless steel flanged concentric reducer installations (Water Online: The Role of Pipe Fittings).

- Process piping in chemical, oil & gas, food industries leverages saddle clamp 1 1 2, saddle clamp 2 inch for branch connections, flow metering, and reliable support.

- Municipal stormwater and agriculture irrigation systems: Extensive use of saddle clamp 1 2 due to rapid installation and seal integrity—even under vibration or ground movement.

- HVAC & fire protection networks: Use of stainless steel flanged concentric reducer (see product detail) to safeguard hydraulic and flow parameters during pipe reduction.

Quality, Certification, and Longevity: What Sets Our Solutions Apart

- Compliant Manufacturing: Adherence to ISO9001, EN1092-1, and ASME standards ensures guaranteed reliability for every stainless steel flanged concentric reducer and saddle clamp produced by HEBEI YONGQIAN TRADING CO.,LTD.

- Advanced Coating Systems: All saddle clamps equipped with blue epoxy resin for exceptional rust protection and an EPDM gasket for watertight performance (ScienceDirect: Epoxy Coating).

- Material Traceability: Strict raw material sourcing (certified GGG50, SS304/316) with full production traceability.

- Lifecycle Performance: In-house testing indicates service life exceeding 25 years in typical water and HVAC environments.

Professional FAQ Section

Frequently Asked Technical Questions

1. What is the recommended material for stainless steel flanged concentric reducer in corrosive media?

For highly corrosive environments, SS316/SS316L is recommended as it offers greater resistance to chlorides and acids than SS304. [Corrosionpedia]

For highly corrosive environments, SS316/SS316L is recommended as it offers greater resistance to chlorides and acids than SS304. [Corrosionpedia]

2. How should I choose between concentric and eccentric reducers?

Choose concentric when the pipeline is vertically aligned or when matching the centerline is critical; eccentric is for horizontal installations where air pockets or elevation changes must be managed.

Choose concentric when the pipeline is vertically aligned or when matching the centerline is critical; eccentric is for horizontal installations where air pockets or elevation changes must be managed.

3. What sealing options are available for Saddle Clamp For PVC/PE Pipe?

Gaskets include EPDM for potable water, copper rings for conductivity, and custom synthetic rubbers for chemical resistance.

Gaskets include EPDM for potable water, copper rings for conductivity, and custom synthetic rubbers for chemical resistance.

4. What sizes are available for saddle clamp 1 1 2 and saddle clamp 2 inch?

Standard production covers 1", 1 1/2", 2", 3", and 4". Custom diameters can be supplied on request.

Standard production covers 1", 1 1/2", 2", 3", and 4". Custom diameters can be supplied on request.

5. What is the standard pressure class for these saddle clamps?

Our saddle clamps are generally supplied in PN10, PN16, PN25, and PN40 based on project requirement and pipe wall thickness.

Our saddle clamps are generally supplied in PN10, PN16, PN25, and PN40 based on project requirement and pipe wall thickness.

6. Which flange standard is best suited for international oil & gas projects?

Most international projects specify ASME B16.5 or EN1092-1 flanges for compatibility with existing networks.

Most international projects specify ASME B16.5 or EN1092-1 flanges for compatibility with existing networks.

7. What are the key installation standards to consider?

Follow ASME B31.3 (for process piping), EN805 (water supply), and manufacturer torque/pre-tension instructions for bolts to ensure reliable assembly and sealing.

Follow ASME B31.3 (for process piping), EN805 (water supply), and manufacturer torque/pre-tension instructions for bolts to ensure reliable assembly and sealing.

Conclusion: The Future of Piping Reliability

As regulatory benchmarks rise and project owners demand longer-lasting, low-maintenance piping systems, solutions like the stainless steel flanged concentric reducer and high-quality saddle clamps are now pivotal for system integrity and service economy. HEBEI YONGQIAN TRADING CO.,LTD. combines cutting-edge engineering with rigorous certification to deliver products that stand the test of time. Our stainless steel flanged concentric reducer and complete saddle clamp range are engineered for excellence.

Contact us for technical guidance, quotations, or bulk project solutions:

Contact us for technical guidance, quotations, or bulk project solutions:

- Phone: +8615130998744

- Email: hebyongqian@gmail.com

- Website: https://www.hbyqmetal.com

References / Further Reading:

[1] Concentric Reducer Market Report: Pipefittingnews

[2] Pipe Fittings in Modern Water Systems: Water Online

[3] Epoxy Coating in Piping: ScienceDirect

[4] Corrosion Resistance of Stainless Steel: Corrosionpedia

[5] Saddle Clamp Installation & Standards: ENG-TIPS Forum

[1] Concentric Reducer Market Report: Pipefittingnews

[2] Pipe Fittings in Modern Water Systems: Water Online

[3] Epoxy Coating in Piping: ScienceDirect

[4] Corrosion Resistance of Stainless Steel: Corrosionpedia

[5] Saddle Clamp Installation & Standards: ENG-TIPS Forum