6% Butterfly Valve with Actuator for Efficient Flow Control Solutions

Understanding the 6% Butterfly Valve with Actuator

In the world of industrial piping systems, the butterfly valve plays a crucial role in regulating flow. Among the various types of butterfly valves, those integrated with actuators provide a level of control that is indispensable in many applications. The 6% butterfly valve with actuator presents a unique solution for precise flow management in diverse industrial settings.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn valve that uses a rotating disk to control the flow of fluid. Its design is simple yet highly effective, making it a popular choice in many industries, including water supply, oil and gas, and chemical processing. The valve operates by rotating the disk inside the body of the valve, allowing or restricting fluid flow based on its position.

The term butterfly stems from the appearance of the disk when it is turned. Just like a butterfly’s wings, the disk moves through a quarter turn—open or closed—providing quick and efficient regulation of flow. Butterfly valves are particularly valued for their lightweight construction, compact size, and ability to handle large volumes of fluid.

The Importance of Actuators

An actuator is a mechanical device that moves or controls a mechanism. When integrated with a butterfly valve, it enables remote operation and automation, ensuring precise control of fluid flow without the need for manual intervention. Actuators can be electric, pneumatic, or hydraulic, each offering different advantages based on the application requirements.

Using actuators with butterfly valves enhances efficiency. For instance, an electric actuator can be programmed to open or close the valve at specific intervals, reducing the risk of human error and ensuring that operating conditions remain optimal. This feature is particularly beneficial in systems where flow rates need to be carefully managed to prevent overflow or pressure build-up.

Advantages of the 6% Butterfly Valve with Actuator

The designation 6% typically refers to the valve's allowable flow capacity or its ability to handle specific flow rates under varying conditions. The 6% butterfly valve with actuator can be strategically selected for applications that require precise flow regulation while maintaining energy-efficient operation. Here are several key advantages

6 butterfly valve with actuator

1. Precision Control The actuator allows for fine-tuned adjustments to the valve position, delivering precise control over fluid flow rates. This is vital in processes where accurate flow measurement is crucial.

2. Quick Response Time With quick operation capabilities, the butterfly valve with actuator can respond rapidly to changes in operational conditions, enhancing the overall efficiency of the piping system.

3. Reduced Maintenance Electric and pneumatic actuators often require less maintenance compared to manual systems. This reliability can minimize downtime and extend equipment lifespan.

4. Energy Efficiency Properly sized and operated valves help reduce energy consumption by ensuring that systems are not working harder than necessary to maintain flow, contributing to sustainable industrial practices.

5. Versatility The 6% butterfly valve with actuator can be used in a range of environments, from water treatment plants to chemical manufacturing facilities. Their reliability in demanding situations makes them a preferred choice among engineers and operators.

Applications in Industry

The combination of a butterfly valve and an actuator is found in numerous applications across various industries. In water treatment facilities, for example, these valves can regulate the flow of water through filtration and distribution processes, maintaining a balance between supply and demand. In chemical processing, precise control is necessary to manage the flow of potentially dangerous substances, and the 6% butterfly valve is designed to handle such requirements safely.

Conclusion

The 6% butterfly valve with actuator reflects a fusion of engineering efficiency and mechanical simplicity, making it a vital component in modern industrial applications. By enabling precise flow regulation, quick response times, and lower maintenance needs, this valve enhances operational efficiency, paving the way for sustainable practices in various sectors. As industries continue to seek ways to optimize performance and reduce costs, the versatile butterfly valve stands out as an intelligent solution for managing fluid flow effectively.

-

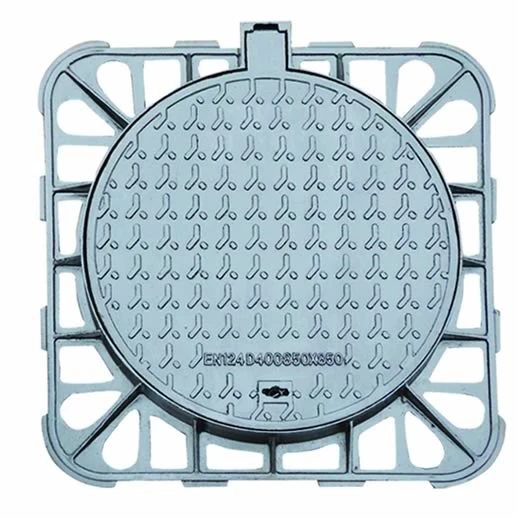

The Essential Component for Safe Urban InfrastructureNewsMay.14,2025

-

The Backbone of Urban InfrastructureNewsMay.14,2025

-

Practical and Stylish Solutions for Your Drainage NeedsNewsMay.14,2025

-

Lamphole Frame and Cover: Essential for Urban InfrastructureNewsMay.14,2025

-

A Seamless and Aesthetic SolutionNewsMay.14,2025

-

A Must-Have for Safety and DurabilityNewsMay.14,2025

-

Pipe Repair Clamps: Your Ultimate Solution for Efficient RepairsNewsMay.09,2025