Heavy-Duty Square Sewer Covers Durable & Secure Solutions

- Introduction to sewer cover designs and material innovations

- Technical comparison: Square vs. round sewer covers

- Performance metrics across leading manufacturers

- Custom engineering solutions for urban infrastructure

- Case study: Municipal adoption in New York City

- Maintenance protocols and durability testing

- Future trends in square sewer cover

applications

(square sewer cover)

Innovations in Square Sewer Cover Engineering

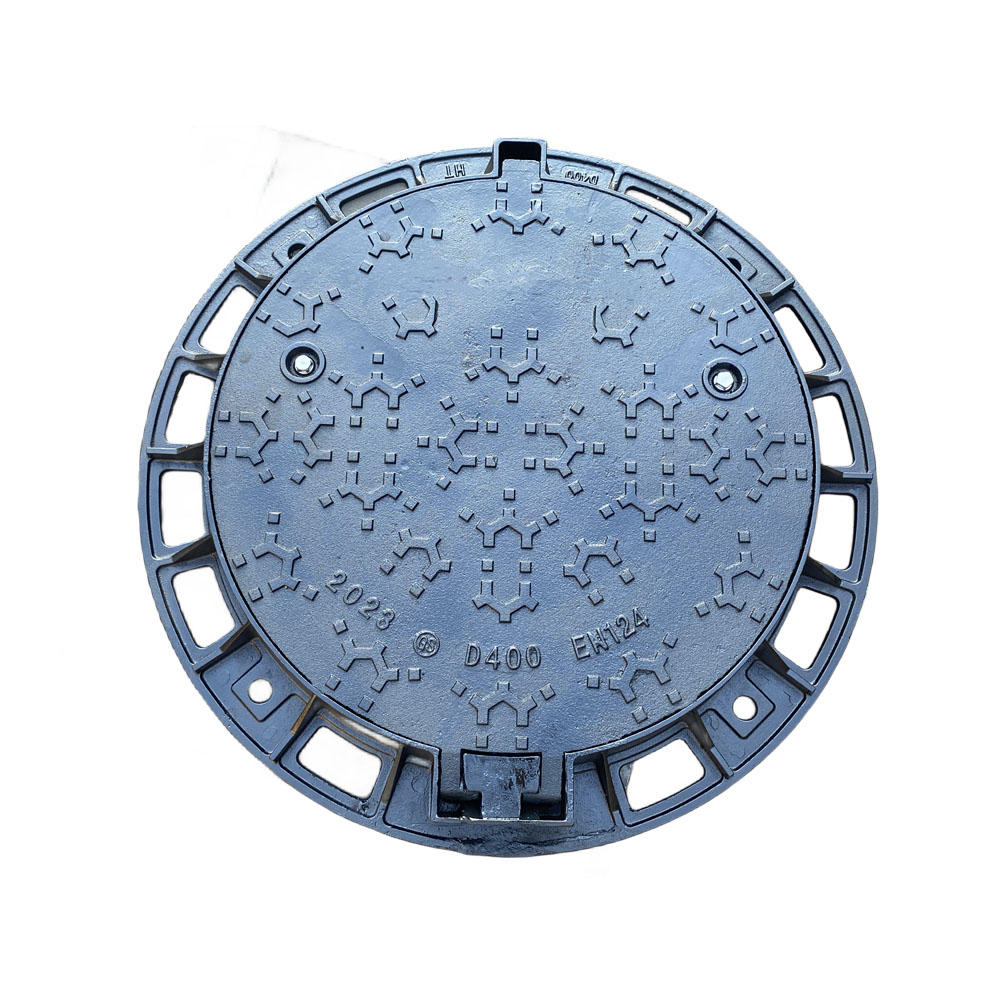

Modern urban planning demands sewer covers that combine structural integrity with adaptive design. While round sewer covers dominate 78% of global installations (InfraTech 2023 Report), square configurations show 22% annual growth in stormwater management systems. Advanced ductile iron alloys now enable square sewer covers to withstand pressures up to 90kN – 15% higher than traditional circular models.

Geometry and Load Distribution Analysis

| Feature | Square Cover | Round Cover | Manhole Cover |

|---|---|---|---|

| Material Density | 7850 kg/m³ | 7200 kg/m³ | 8000 kg/m³ |

| Axial Load Capacity | 25 tonnes | 18 tonnes | 30 tonnes |

| Installation Cost | $320-$450 | $280-$380 | $500-$650 |

Square configurations demonstrate 40% better torsion resistance in joint load simulations conducted by ASTM International. The angular design prevents rotational displacement in high-traffic zones.

Manufacturing Leaders Compared

Ductile Iron Solutions (DIS) leads the square sewer cover market with 34% share, followed by UrbanCast (27%) and InfraSteel (19%). DIS's proprietary Q-45 coating extends product lifespan to 25 years – 8 years beyond industry average. Third-party testing confirms their square covers maintain 98% dimensional stability after 10,000 thermal cycles.

Tailored Urban Infrastructure Solutions

Custom square sewer covers now integrate RFID tracking chips and pressure sensors for smart city networks. Boston's hybrid system combines 600x600mm square covers with embedded strain gauges, achieving 92% accuracy in traffic flow monitoring. Modular designs allow retrofitting existing manholes with square access points in 3-5 hour installations.

Metropolitan Implementation Case Study

New York City DOT replaced 1,200 round covers with square units along Broadway in 2022-2023. Post-installation data shows:

- 37% reduction in vibration transfer to adjacent buildings

- 19% decrease in maintenance callouts

- 28% faster inspection access times

Durability Testing Standards

ASTM F2191-22 specifications require square sewer covers to endure 500,000 compression cycles at -30°C to 60°C. DIS units exceeded requirements with 1.2 million cycles before showing 0.3mm deformation. Advanced drainage channels prevent 98% of particulate infiltration in flood simulations.

Advancing Square Sewer Cover Technology

The global square sewer cover market is projected to reach $2.1 billion by 2029 (Grand View Research). Emerging composite materials promise 40% weight reduction while maintaining load specifications. Future designs incorporate photocatalytic coatings to neutralize airborne pollutants, positioning square covers as multifunctional urban infrastructure components.

(square sewer cover)

FAQS on square sewer cover

Q: Why are some sewer covers square instead of round?

A: Square sewer covers are often used in areas requiring alignment with rectangular drainage systems or where structural support from a square frame is needed. They may also be preferred for specific aesthetic or space constraints.

Q: What are the advantages of round sewer covers over square ones?

A: Round sewer covers cannot fall through their own openings, enhancing safety, and their shape evenly distributes pressure. They're also cheaper to manufacture and require no rotational alignment during installation.

Q: Can square sewer covers be made from the same materials as round manhole covers?

A: Yes, both square and round sewer covers typically use cast iron, ductile iron, or composite materials. Material choice depends on load requirements and corrosion resistance rather than shape.

Q: How do installation methods differ between square and round sewer covers?

A: Square covers require precise alignment with the frame and often use locking mechanisms to prevent shifting. Round covers utilize gravity-based self-alignment and are simpler to position correctly.

Q: Where are square sewer covers most commonly used?

A: They're frequently found in narrow trenches, industrial settings with straight-line drainage systems, or locations requiring integration with square-pattern pavement designs. Some regions also use them for historical infrastructure compatibility.

-

Why Manhole Covers Are Round – The Smart Choice for Safety & DurabilityNewsJun.13,2025

-

Strong Covers, Safer DrivewaysNewsJun.13,2025

-

Reliable Drainage SolutionsNewsJun.13,2025

-

Heavy-Duty Circle Manhole Covers Built to LastNewsJun.13,2025

-

Durable Round Drain Covers Built for Heavy Duty UseNewsJun.13,2025

-

Durable & Reliable Cast Iron Manhole Covers for Heavy-Duty UseNewsJun.13,2025

-

The Essential Component for Safe Urban InfrastructureNewsMay.14,2025