Specifications and Applications of DN80 Gate Valve in Industrial Settings

Understanding the DN80 Gate Valve A Key Component in Fluid Control Systems

In various industrial and plumbing applications, gate valves play a critical role in controlling the flow of fluids. One such widely used component is the DN80 gate valve. The term DN stands for “Diameter Nominal,” which refers to the valve's nominal diameter in millimeters. Thus, a DN80 gate valve has a nominal size of 80 mm, making it suitable for a range of fluid control purposes.

Gate valves are designed to allow or restrict flow through a pipeline, providing a robust solution for isolating sections of a system. This functionality is particularly useful in situations where complete shut-off is necessary, such as in steam, water, or gas systems. Unlike other valve types, such as ball or butterfly valves, gate valves are characterized by their straightforward open and close operation. Their design includes a gate or wedge that moves up and down to either block or permit fluid passage.

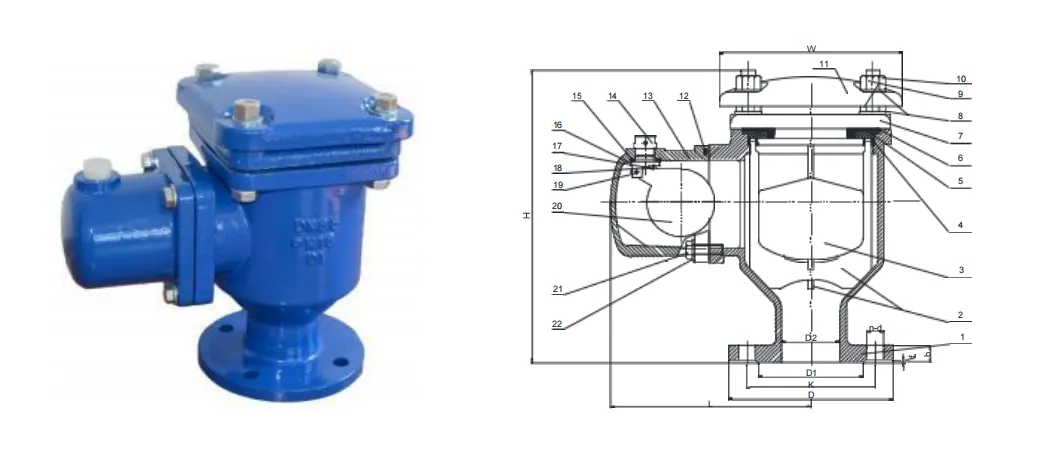

Design and Construction

The DN80 gate valve is typically constructed from durable materials like cast iron, stainless steel, or carbon steel. The choice of material depends on the specific application and the type of fluid being handled. For instance, corrosive fluids may require stainless steel valves to prevent degradation. The valve's sealing mechanism is crucial, as a proper seal ensures that no leaks occur when the valve is closed, maintaining system integrity.

The design of the DN80 gate valve also features either a rising or non-rising stem. In rising stem designs, the stem rises out of the valve body when the valve is opened, providing visual confirmation of the valve's position. Non-rising designs, on the other hand, are beneficial in situations where space is limited, as the stem remains inside the valve body during operation.

Operation and Installation

To operate a DN80 gate valve, one typically uses a manual handwheel, although there are options for electric or pneumatic actuators that provide automated control. Turning the handwheel raises or lowers the gate, allowing for easy control over fluid flow. It is important to note that gate valves are best used in fully open or fully closed positions. Operating a gate valve partially open can lead to increased wear and tear, potentially causing damage over time.

gate valve dn80

When installing a DN80 gate valve, it is essential to consider its orientation. These valves can be installed in any position, but horizontal installation is most common. Proper alignment with the pipeline is crucial to avoid undue stress on the valve's components. Additionally, using adequate gaskets and bolting techniques ensures that leaks do not occur during operation.

Applications

The DN80 gate valve finds applications across various sectors, including water supply, wastewater treatment, oil and gas, and chemical processing. In municipal water systems, these valves can isolate sections of pipe for maintenance without disrupting the entire system. In industrial settings, they can control the flow of fluids through large pipelines, enabling efficient production processes.

Advantages and Limitations

The widespread use of DN80 gate valves can be attributed to several advantages. Their design permits minimal pressure drop when the valve is fully open, making them suitable for systems requiring unrestricted flow. Furthermore, their simple construction means they are generally easier to maintain.

However, there are limitations to be mindful of. Gate valves are not ideal for throttling applications, as their performance can lead to turbulence and erosion inside the valve. Additionally, they tend to be bulkier compared to other valve types, which may be a concern in space-constrained environments.

Conclusion

In conclusion, the DN80 gate valve is an essential component in many fluid control systems. Its design, reliability, and range of applications make it a preferred choice for industries requiring effective flow regulation. Understanding its functionality and proper installation techniques is vital for ensuring optimal performance and longevity in any system where it is implemented. As industries continue to evolve, the DN80 gate valve will remain a mainstay in fluid management solutions.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025