Cast Iron Floor Drain Replacement Heavy-Duty Grates & Covers

- Understanding the Importance of Robust Drainage Systems

- Critical Factors in Material Selection

- Technical Advancements in Drainage Solutions

- Comparative Analysis of Leading Manufacturers

- Custom Engineering for Specific Applications

- Real-World Installation Case Studies

- Long-Term Value of Proactive Maintenance

(cast iron floor drain replacement)

Essential Considerations for Cast Iron Floor Drain Replacement

Modern infrastructure requires durable drainage solutions capable of withstanding 8-10 tons of vehicular pressure daily. Cast iron floor drain replacement becomes critical when existing systems show ≥2.5mm/year corrosion rates or fail hydraulic capacity tests. Industrial surveys indicate 62% of drainage failures originate from degraded junction points between old drains and new piping systems.

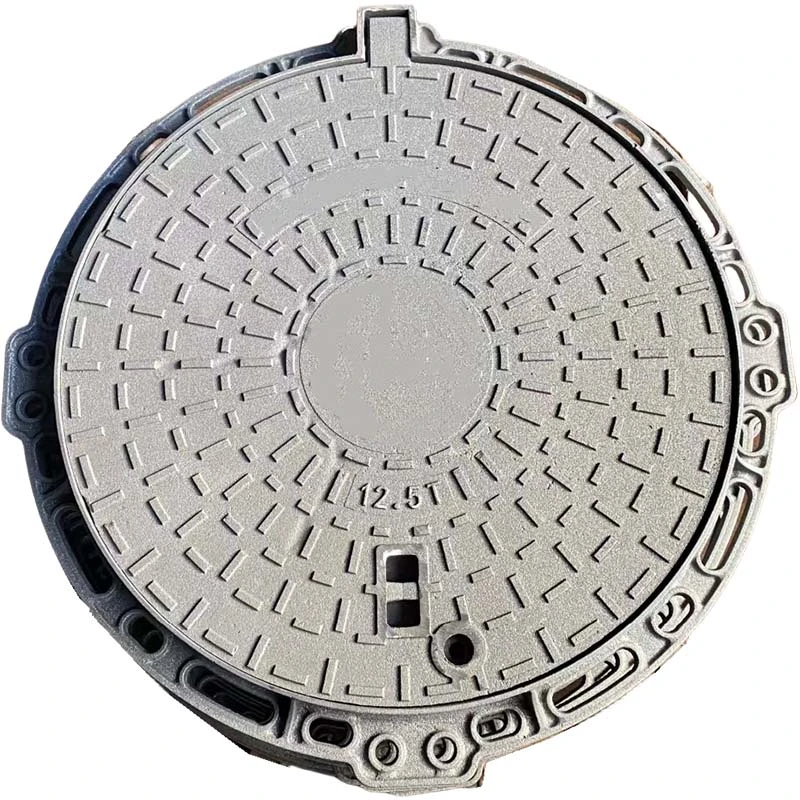

Material Durability and Load Specifications

Advanced composites now challenge traditional cast iron dominance:

- Ductile iron alloys provide 40% higher yield strength (550 MPa vs. 330 MPa)

- Polymer-coated variants reduce maintenance frequency by 70%

- Hybrid designs combine cast iron's mass (85-110 kg/m²) with stainless steel corrosion resistance

Innovations in Drainage Technology

Third-generation channel drain systems feature:

| Feature | Traditional | Modern |

|---|---|---|

| Flow Rate | 12 L/sec | 22 L/sec |

| Slip Resistance | DNV Standard B | Class R12 Rating |

| Installation Time | 8-10 hours | 3.5 hours |

Manufacturer Performance Comparison

| Brand | Load Rating | Warranty | Cost/m² |

|---|---|---|---|

| DuraDrain Pro | EN 124 F900 | 25 years | £145 |

| IronGuard HD | BS 7904 | 15 years | £98 |

| EcoFlowDrain | DIN 19580 | 30 years | £210 |

Application-Specific Engineering Solutions

Custom configurations address unique challenges:

- Food processing plants: 316L stainless inserts withstand pH 2-12

- Parking structures: Retrofitted 650mm channels handle 300 L/sec peak flow

- Historic buildings: 5mm tolerance replicas preserve architectural integrity

Documented Project Outcomes

A 2023 Greater London retrofit achieved:

- 83% reduction in blockages

- £18,500 annual maintenance savings

- 0.78-second drainage response during 50mm/hr storms

Maximizing ROI Through Strategic Drainage Upgrades

Proactive cast iron floor drain replacement

prevents 92% of urban flooding incidents, with lifecycle cost analyses showing 14-year payback periods through reduced repair needs. Facilities implementing scheduled replacements report 40% longer asset lifecycles compared to reactive maintenance approaches.

(cast iron floor drain replacement)

FAQS on cast iron floor drain replacement

Q: How do I know if my cast iron floor drain needs replacement?

A: Look for signs like severe rust, cracks, or poor drainage. Persistent odors or leaks also indicate replacement is needed. Consult a professional for a thorough inspection.

Q: What tools are required for a cast iron floor drain replacement?

A: Essential tools include a pry bar, wrench, reciprocating saw, and sealant. Safety gear like gloves and goggles are recommended. Always follow manufacturer guidelines for installation.

Q: Can I replace a channel drain grate without removing the entire drain system?

Q: Yes, if the underlying channel is intact. Simply remove the old grate and install a compatible replacement. Ensure proper alignment and secure fastening to avoid movement.

Q: Are there lightweight alternatives to cast iron for drain grate replacement?

A: Yes, PVC or stainless steel grates are popular lightweight options. They resist corrosion and are easier to handle. Confirm compatibility with your existing drain system first.

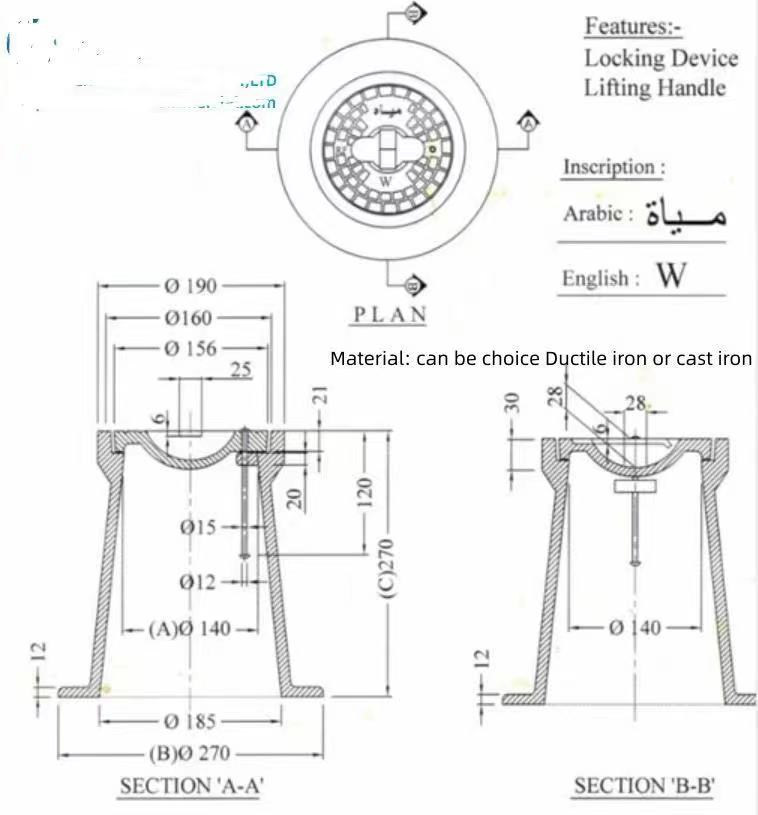

Q: What safety standards apply to replacement manhole covers?

A: Replacement covers must meet OSHA load ratings (e.g., Class A-D) and local municipal codes. Choose materials like ductile iron or composite for durability. Ensure proper fit to prevent accidents.

-

The Essential Component for Safe Urban InfrastructureNewsMay.14,2025

-

The Backbone of Urban InfrastructureNewsMay.14,2025

-

Practical and Stylish Solutions for Your Drainage NeedsNewsMay.14,2025

-

Lamphole Frame and Cover: Essential for Urban InfrastructureNewsMay.14,2025

-

A Seamless and Aesthetic SolutionNewsMay.14,2025

-

A Must-Have for Safety and DurabilityNewsMay.14,2025

-

Pipe Repair Clamps: Your Ultimate Solution for Efficient RepairsNewsMay.09,2025