Air Release Valves for Efficient Pipeline Management and Performance Optimization

Air Valve for Pipeline A Crucial Component in Fluid Transport Systems

The efficient transport of fluids through pipelines is crucial for various industries, including water supply, oil and gas, and chemical processing. Among the myriad components that facilitate smooth pipeline operation, air valves play a pivotal role. This article delves into the significance, types, functions, and benefits of air valves in pipeline systems.

Understanding Air Valves

Air valves are specially designed devices that manage air flow in pipeline systems. Their primary function is to prevent the accumulation of air, which can lead to pressure fluctuations, inefficiencies, and potential damage to the pipeline. These valves perform two essential functions allowing air to escape from the pipeline during fluid flow and enabling air to enter when the pipeline is drained or emptied. By maintaining optimal pressure levels, air valves ensure the smooth operation of the entire pipeline network.

The Importance of Air Valves

1. Preventing Air Accumulation When air gets trapped in a pipeline, it creates pockets of air that can impede fluid flow. This can lead to inefficient transport, increased energy costs, and potential damage to the pipeline infrastructure due to water hammer or pressure surges. Air valves effectively release these trapped air pockets, ensuring uninterrupted fluid movement.

2. Pressure Regulation Air valves play a critical role in regulating pressure within the pipeline. By allowing excess air to escape, they help maintain consistent pressure, reducing the risk of rupture or failure. This is particularly important in high-pressure systems where even minor pressure fluctuations can have catastrophic consequences.

3. Facilitating Maintenance During maintenance or repairs, air valves enable the safe and efficient draining of pipelines. By allowing air to enter the system, they help facilitate the complete removal of fluids, minimizing the risks associated with leaks and spills. This makes routine maintenance easier and safer for personnel involved.

Types of Air Valves

1. Air Release Valves These are designed to release air that has been trapped in the pipeline. They automatically open when air pressure exceeds a preset level and close as the pressure stabilizes.

air valve for pipeline

2. Combination Air Valves As the name suggests, combination air valves incorporate both air release and air intake functionalities. They allow for the release of accumulated air during fluid flow and the intake of air when the pipeline is being drained.

3. Vacuum Breaker Valves These valves prevent the formation of a vacuum in the pipeline that can occur when the fluid level drops rapidly. By allowing air to enter the system, vacuum breaker valves protect against potential collapse of the pipeline structure.

Benefits of Using Air Valves

1. Enhanced Efficiency By preventing air pockets and maintaining optimal pressure levels, air valves improve the overall efficiency of fluid transport. This translates to reduced energy consumption and lower operational costs.

2. Reduced Maintenance Costs Though air valves require periodic inspection and maintenance, their ability to prevent significant issues such as pipeline ruptures can save companies considerable amounts in repair costs and downtime.

3. Increased Safety The use of air valves minimizes the risk of pressure surges and water hammer effects, which can pose serious safety hazards. By ensuring that the pipeline operates smoothly, air valves contribute to a safer working environment.

4. Longevity of Infrastructure By actively preventing detrimental conditions such as pressure fluctuations and vacuum creation, air valves help extend the lifespan of pipelines and associated infrastructure.

Conclusion

In conclusion, air valves are an indispensable component of modern pipeline systems, ensuring efficient fluid transport while maintaining safety and operational integrity. Their ability to manage air flow, regulate pressure, and facilitate maintenance makes them essential for industries relying on pipelines for their operations. As technology continues to evolve, the design and functionality of air valves will likely improve, further enhancing their role in fluid transport systems. Implementing effective air valve solutions can lead to enhanced efficiency, reduced costs, and increased safety—benefits that are vital in today's competitive industrial landscape.

-

Square Sewer Cover Enhances Urban SafetyNewsAug.01,2025

-

Pipe Fitting Requires Precise AlignmentNewsAug.01,2025

-

Manhole Step Is DurableNewsAug.01,2025

-

Manhole Cover Is Found WorldwideNewsAug.01,2025

-

Hole Cover Frame On RoadsNewsAug.01,2025

-

Gully Grate Improves Road SafetyNewsAug.01,2025

-

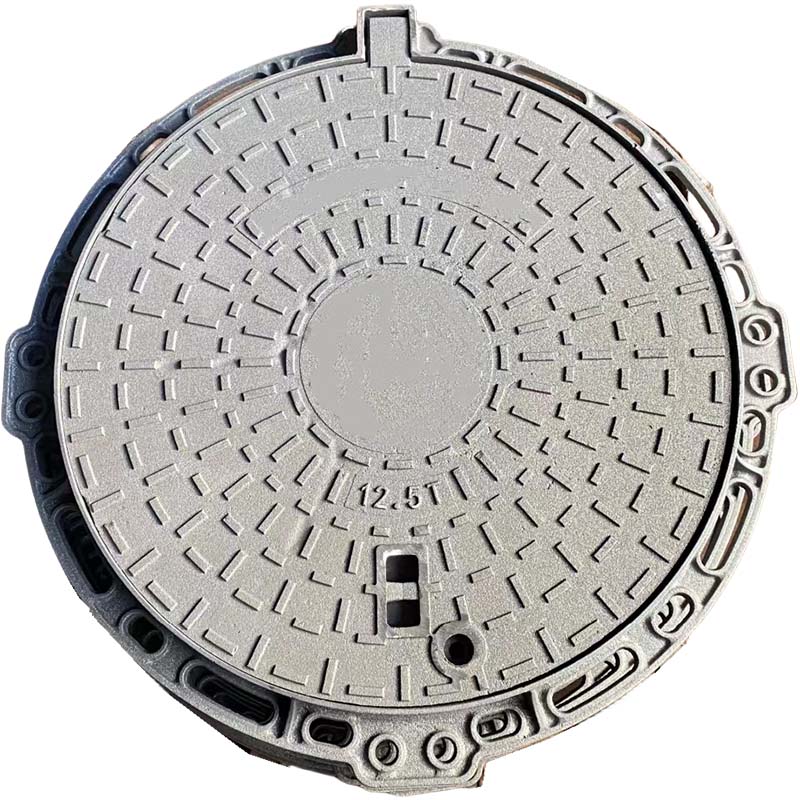

Man Hole Cover Round Load CapacityNewsJul.31,2025