water well air release valve

Understanding Water Well Air Release Valves

Water well systems are essential for providing clean water to households and industries globally. However, efficient operation of these systems depends on various components, one of the most crucial being the air release valve. Air release valves play a significant role in ensuring the smooth operation of water wells by preventing the accumulation of air within the pipelines, which can lead to operational inefficiencies, decreased water quality, and potential damage to the system. This article delves into the importance, functionality, and maintenance of air release valves in water well systems.

Importance of Air Release Valves

Air release valves are designed to automatically manage the air pressure within a water well system. When water flows through pipelines, air can enter the system through various means, including leaks and atmospheric pressure changes. This trapped air can create air pockets, leading to several complications, such as water hammer, reduced flow rates, and increased wear on pumps and other mechanical components. By expelling excess air, air release valves maintain optimal system pressure, enhance the efficiency of water delivery, and extend the lifespan of the equipment involved.

The importance of air release valves further extends to maintaining water quality. If air pockets are allowed to accumulate, they can lead to stagnation in certain areas, which may result in microbial growth and reduced water quality. Air release valves help prevent these conditions, ensuring that the water remains clean and safe for consumption.

Functionality of Air Release Valves

Air release valves operate on a simple principle they allow air to escape from the pipeline when pressure builds up, and they also prevent any contaminants from entering the system. Typically, these valves consist of a float mechanism and a discharge orifice. When air accumulates, the float drops, allowing the trapped air to escape. Once the pressure is released, the float rises back, sealing the orifice to prevent water from leaking out.

water well air release valve

These valves are typically installed at high points within a water pressure system or near pumps. Their strategic placement ensures that air is eliminated efficiently throughout the system. Some advanced models also feature anti-siphon mechanisms, which further safeguard against backflow and contamination.

Maintenance of Air Release Valves

To ensure that air release valves function effectively, regular maintenance is crucial. Over time, debris and sediment can accumulate, obstructing the valve mechanism. Routine inspection helps identify any signs of wear or damage that could impair the valve's operation. Operators should regularly clean the valve and its surroundings to prevent blockages. Additionally, testing the valve functionality helps confirm that it opens and closes properly in response to pressure changes.

Another aspect of maintenance involves checking for leaks in the pipelines. Since air can infiltrate through even the smallest gaps, ensuring the integrity of the entire system is vital for the efficiency of air release valves. Operators should also ensure that all fittings, joints, and connections are secure.

Conclusion

In summary, air release valves are indispensable components in water well systems, playing a vital role in ensuring proper operation, maintaining water quality, and safeguarding equipment. Their functionality is straightforward yet critical, as they help eliminate trapped air and prevent the associated issues that might arise from it. Regular maintenance is necessary to ensure that these valves operate effectively, providing optimal performance throughout the lifespan of the water well system. Through proper understanding and attention to air release valves, operators can ensure the efficient functioning of their water systems, ultimately contributing to improved water service and quality for users.

-

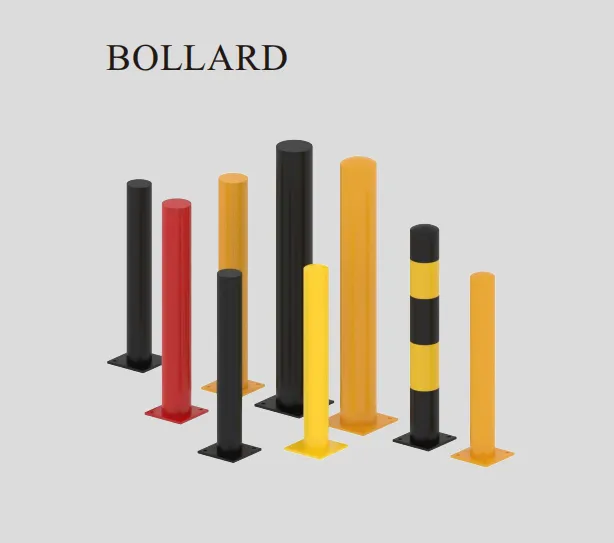

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025