Wafer Type Butterfly Valve Pricing and Market Insights for 2023

Understanding the Pricing of Wafer Type Butterfly Valves

Butterfly valves are critical components in various industrial applications, particularly in the control and isolation of flow within pipes. Among the different types of butterfly valves available, the wafer type butterfly valve is widely recognized for its compact design, lightweight structure, and ease of installation. Given its increasing popularity, it is essential to understand the factors influencing the pricing of wafer type butterfly valves and how these factors impact customers when making purchasing decisions.

What is a Wafer Type Butterfly Valve?

A wafer type butterfly valve is designed to fit between two flanges in a piping system, allowing for a more straightforward installation compared to other valve types. Its compact design makes it an attractive choice for applications with space constraints. The core component consists of a circular disc that rotates on an axis, which either allows or restricts flow through the pipeline. This type of valve is commonly used in water and wastewater treatment, HVAC systems, and various industrial processes.

Factors Influencing Pricing

1. Material Composition The materials used in manufacturing wafer type butterfly valves significantly affect their price. Common materials include stainless steel, cast iron, and PVC. Stainless steel valves, for instance, tend to be more expensive due to their durability and resistance to corrosion, making them suitable for demanding environments. In contrast, PVC valves may be less expensive and are ideal for applications involving non-corrosive fluids.

2. Size and Diameter The size of the valve plays a crucial role in determining its price. Larger valves generally require more material and more robust construction to handle higher pressures and flow rates, leading to increased costs. Customers must carefully assess their specific application requirements to select the appropriate valve size, balancing performance needs with budget constraints.

3. Pressure Ratings Wafer type butterfly valves come with varying pressure ratings. Valves designed for high-pressure applications typically incorporate advanced engineering and materials, which also drives up the price. Understanding the operational pressure requirements is essential, as selecting a valve with an unsuitable pressure rating can lead to operational failures and additional costs.

wafer type butterfly valve price

4. Manufacturing Processes The complexity of the manufacturing process can also influence pricing. Valves that undergo rigorous quality control, such as testing for leakage and durability, often come with a higher price tag. The methods used for production, whether cast or forged, also significantly impact costs.

5. Brand and Reputation Established brands with a proven track record of quality and reliability may charge a premium for their products. Customers often find value in purchasing from recognized manufacturers, as this can assure them of the valve's performance and longevity.

6. Market Demand and Supply Chain Dynamics Economic factors such as market demand and supply chain conditions can affect the prices of wafer type butterfly valves. During periods of high demand or supply chain disruptions, prices may rise due to scarcity. Conversely, a surplus in supply can lead to competitive pricing.

7. Customization and Standards Compliance Some applications may require customized butterfly valves to meet specific regulations or performance standards. Custom solutions often come with additional costs, as they may require special materials, unique dimensions, or additional features.

Conclusion

When considering the purchase of wafer type butterfly valves, understanding the various factors influencing their pricing is essential. Customers should evaluate their specific requirements, including material preferences, size, pressure ratings, and budget constraints. By comprehensively assessing these elements, buyers can make informed decisions that align with their operational needs while ensuring cost-effectiveness.

In the end, choosing the right wafer type butterfly valve involves a balance between quality, functionality, and price. Given the importance of these components in maintaining the efficiency and safety of industrial processes, investing in the right valve can yield significant long-term benefits, making it a crucial aspect of any industrial procurement strategy.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

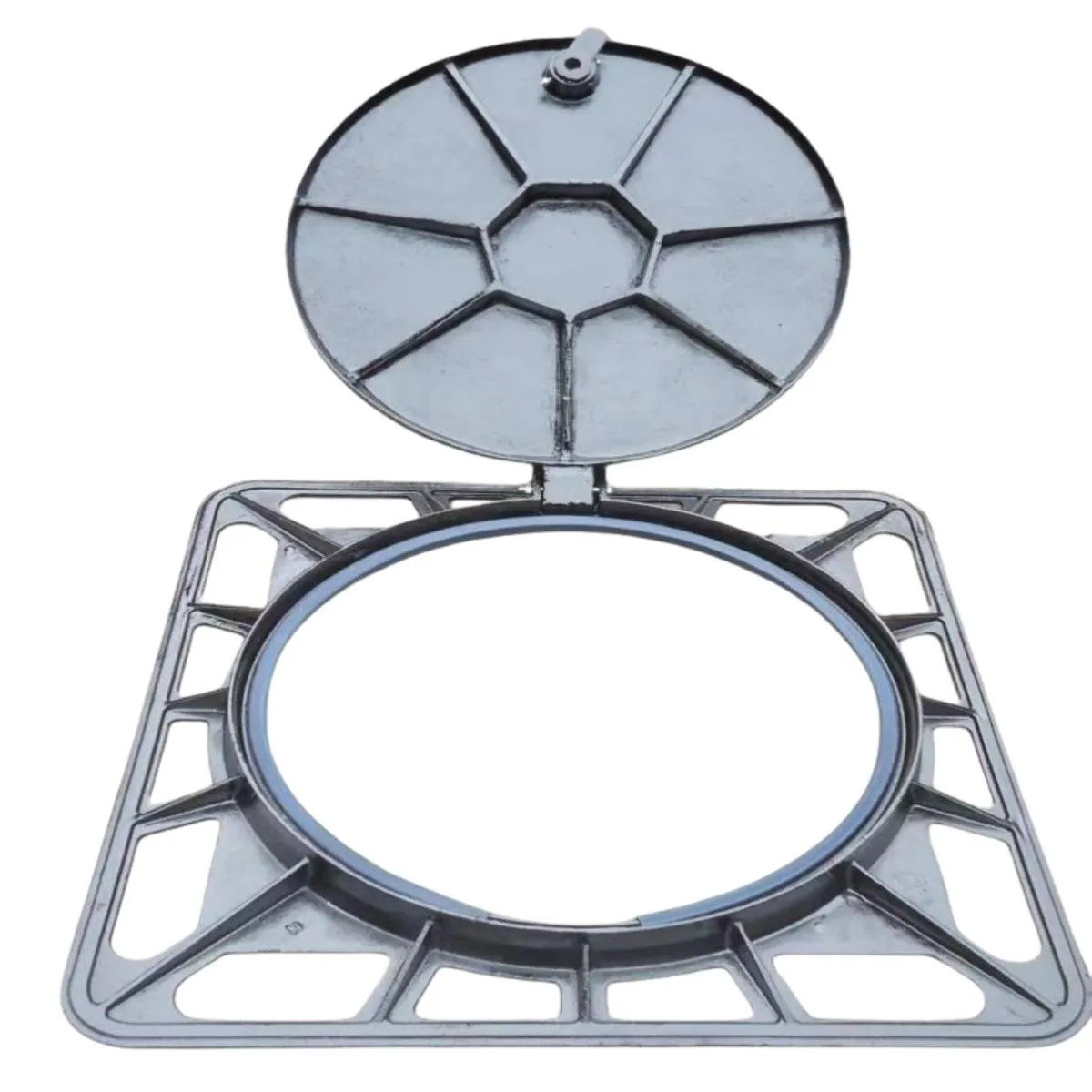

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025