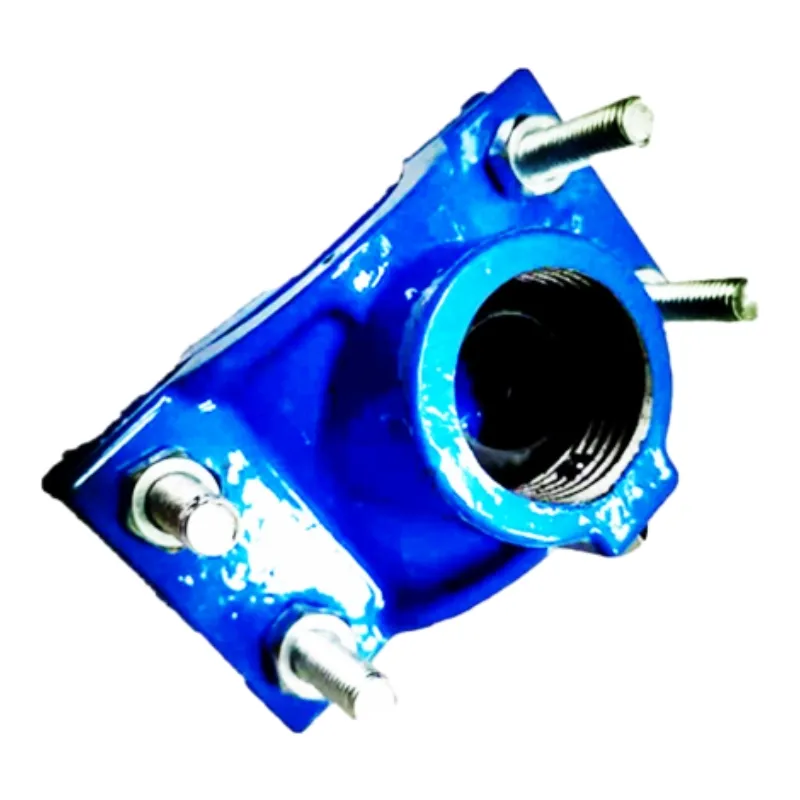

valve butterfly wafer

Understanding Valve Butterfly Wafer A Key Component in Fluid Control

In industrial applications, the efficient control of fluid flow is crucial for operational success. Among various tools and equipment used to manage fluid movement, the valve butterfly wafer stands out as a highly efficient, versatile, and compact solution. This article delves into the essential features, advantages, applications, and maintenance of valve butterfly wafers.

What is a Valve Butterfly Wafer?

A valve butterfly wafer is a type of flow control device that uses a rotating disc, known as the butterfly, to regulate the flow of substances such as gases, liquids, or slurries. Positioned between two flanges, a wafer-style butterfly valve is designed to be compact, allowing for easy installation and maintenance in piping systems. The mechanism involves a quarter-turn operation, which means that the disc can open or close the flow path with just a 90-degree rotation.

Features of Valve Butterfly Wafers

1. Compact Design The wafer configuration allows for a slim profile, making it suitable for tight spaces within piping systems.

2. Durable Materials Typically constructed from a variety of materials such as stainless steel, cast iron, and plastic, these valves can withstand harsh environments and different chemical compositions.

3. Easy Installation The design allows for quick installation and replacement, minimizing downtime during maintenance or upgrades.

4. Versatile Operation Butterfly valves can be manually operated, electronically actuated, or pneumatically controlled, offering flexibility based on user requirements.

5. Low Pressure Drop When fully opened, the disc is nearly parallel to the flow, resulting in a minimal pressure drop across the valve.

Advantages of Using Valve Butterfly Wafers

1. Cost-Effectiveness Compared to other valve types, such as ball or globe valves, butterfly wafer valves are generally more affordable, making them a popular choice for budget-conscious projects.

valve butterfly wafer

3. Quick Operation The quarter-turn operation makes butterfly valves remarkably fast to open and close, allowing for rapid flow adjustments and increased operational efficiency.

4. Wide Range of Applications Due to their versatile operation and design, butterfly valves can be employed in various industries, including water treatment, HVAC systems, food and beverage processing, chemical manufacturing, and wastewater management.

5. Reduced Maintenance With fewer moving parts compared to other types of valves, butterfly wafer valves often require less maintenance, thus minimizing operational interruptions.

Applications of Valve Butterfly Wafers

Valve butterfly wafers are widely used across different sectors. In water treatment plants, they manage the flow of water through filters, pumps, and tanks. In HVAC systems, they regulate air and refrigerants to maintain optimal temperature levels. The food and beverage industry employs these valves to control the flow of liquids during processing and bottling, ensuring compliance with health standards. Furthermore, chemical manufacturers rely on butterfly valves to manage corrosive substances efficiently.

Maintenance of Valve Butterfly Wafers

To ensure long-term performance, regular maintenance of valve butterfly wafers is essential

1. Periodic Inspection Regularly inspect the valve for signs of wear, corrosion, or leakage to identify issues before they escalate.

2. Lubrication Apply appropriate lubricants to the valve stem and movable parts to ensure smooth operation.

3. Cleaning Keep the valve surface clean to prevent build-up of debris or corrosive substances that may affect functionality.

4. Replacement of Seals Periodically check and replace seals and gaskets to maintain leakage integrity.

Conclusion

Valve butterfly wafers play an indispensable role in fluid control, offering a blend of performance, reliability, and cost-effectiveness. Their unique design and operation make them suitable for various industrial applications. By understanding their features, advantages, and maintenance needs, industries can make informed decisions, thereby ensuring efficient and sustainable operations. In a world where fluid management is critical, investing in quality valve butterfly wafers can contribute significantly to operational success and efficiency.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025