Exploring the Features and Benefits of Valve Butterfly Designs and Applications

Understanding Valve Butterfly 4 A Comprehensive Overview

In the realm of industrial applications, components that ensure the smooth flow of fluids are essential. One such critical element is the valve, particularly the butterfly valve, which has gained favor for its efficiency and reliability. Among the various types of butterfly valves, the Valve Butterfly 4 stands out, particularly for its design, functionality, and application. This article delves into the intricate aspects of the Valve Butterfly 4, its advantages, applications, and the reasons why it is a preferred choice in numerous industries.

Design and Functionality

The Valve Butterfly 4 adopts a unique design characterized by a rotating disc or vane that regulates flow. The disc is strategically mounted within the valve body and is turned by a shaft with a handle or actuator. When the valve is closed, the disc is perpendicular to the flow, effectively blocking it. Conversely, when the valve is open, the disc rotates parallel to the flow, allowing fluid to pass through with minimal resistance.

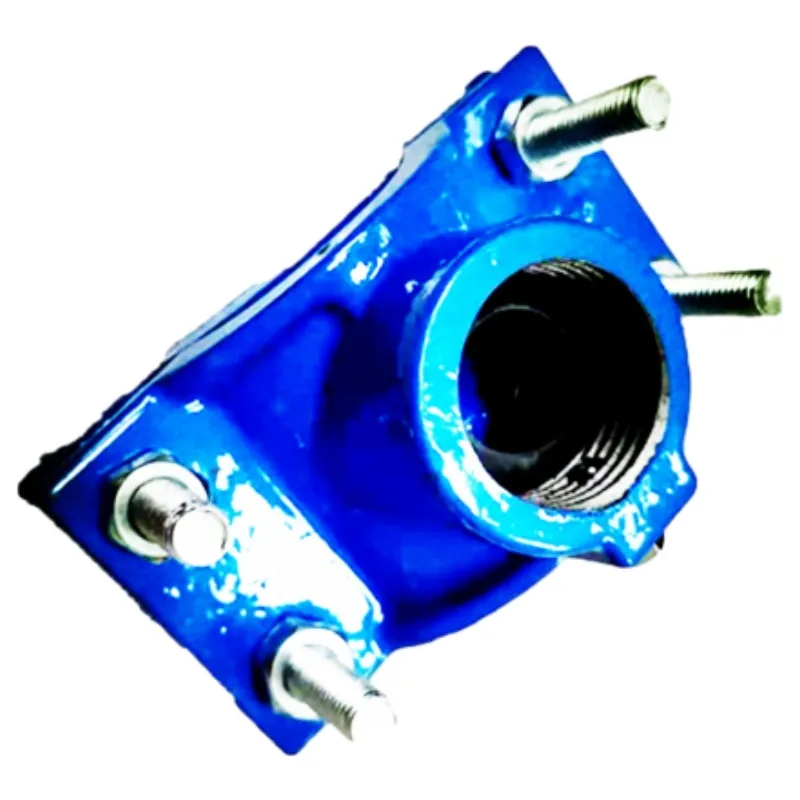

One of the defining features of the Valve Butterfly 4 is its four-bolt flange connection. This robust design ensures a secure fit within various piping systems, minimizing the risk of leaks and maintaining structural integrity under varying pressures. The four-bolt configuration not only enhances the stability of the valve but also simplifies installation and maintenance, making it a practical choice for engineers and technicians.

Advantages

The Valve Butterfly 4 offers a plethora of advantages over traditional valve types. One of the most notable benefits is its lightweight design. Unlike gate or globe valves, which can be cumbersome, the butterfly valve’s slim profile allows for effortless handling and installation. This can be particularly advantageous in environments where space is at a premium.

valve butterfly 4

Another significant advantage is its efficiency in controlling flow. The design of the valve minimizes turbulence, reducing energy loss and enhancing system performance. Moreover, the valve can be operated quickly, making it ideal for applications where rapid response times are crucial.

Additionally, the Valve Butterfly 4 is versatile and suitable for various media, including water, oil, gas, and chemical solutions. Its ability to handle a range of pressures and temperatures makes it adaptable to different operational requirements. This versatility extends to various industries—ranging from water treatment facilities to chemical processing plants, HVAC systems, and even food and beverage production.

Applications

The applications of the Valve Butterfly 4 are extensive. In water treatment facilities, it is commonly used to control the flow of treated water and wastewater. The valve's reliable operation and ability to prevent backflow make it vital in these systems.

In the chemical industry, the valve is favored for its resistance to corrosive substances. The materials used in its construction can be tailored to withstand aggressive chemicals, ensuring longevity and safety in processing environments. Furthermore, in HVAC applications, the Valve Butterfly 4 is utilized to regulate air and steam flow, contributing to energy efficiency and user comfort.

Conclusion

In summary, the Valve Butterfly 4 is a crucial component in modern industrial applications. Its unique design, lightweight construction, and efficient flow control make it an ideal choice for various industries. Whether in water treatment, chemical processing, or HVAC systems, the Butterfly Valve 4 proves to be a reliable and versatile solution. As industries continue to evolve and demand more efficient and adaptable components, the importance of such valves will only grow, solidifying their place in the future of fluid control technologies. Embracing the capabilities of the Valve Butterfly 4 may well be the key to enhanced operational efficiency and reliability in fluid handling systems.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025