triple offset butterfly valve

Understanding the Triple Offset Butterfly Valve A Comprehensive Overview

The triple offset butterfly valve, often referred to simply as the triple offset valve, is an advanced type of butterfly valve designed for a range of industrial applications. Known for its superior performance, the triple offset configuration allows this valve to handle high pressures and temperatures while minimizing the potential for leakage. This article delves into the key features, advantages, and applications of the triple offset butterfly valve.

Design Characteristics

The triple offset butterfly valve is distinct from traditional butterfly valves due to its unique design, which incorporates three offsets. These offsets are

1. First Offset The centerline of the valve disc is offset from the centerline of the seat. This design ensures that there is no rubbing or wear on the seat during operation, significantly increasing the valve's lifespan.

2. Second Offset The axis of the valve disc is positioned away from the seat, allowing the disc to rotate into the seat without making contact until fully closed. This characteristic leads to a tighter seal and reduces the risk of leakage.

3. Third Offset The stem of the valve is positioned behind the plane of the seat, which leads to a conical-shaped seating surface. This offset allows for the use of a high-performance sealing material and creates a wedging action when the valve is closed, further enhancing the seal's effectiveness.

These design aspects ensure that the triple offset butterfly valve operates smoothly, resulting in lower torque requirements compared to traditional butterfly valves.

Advantages

triple offset butterfly valve

One of the primary advantages of utilizing a triple offset butterfly valve is its ability to provide a tight seal, which is essential in applications where leakage can lead to significant safety and environmental concerns. The valve’s design minimizes seat wear and extends service life, thus optimizing maintenance costs and system reliability.

The triple offset butterfly valve is also characterized by its lightweight construction, which simplifies installation and reduces the overall weight of piping systems. Additionally, its quarter-turn operation allows for quick and easy actuation, making it suitable for automated control systems.

Furthermore, the valve is versatile enough to be used in a range of applications involving liquids, gases, and slurries within industries such as oil and gas, power generation, water treatment, and chemical processing. Its capability to handle extreme conditions makes it a preferred choice for many engineers and system designers.

Applications

Given its robust design and functionality, the triple offset butterfly valve can be found in various critical applications. In oil and gas, for instance, these valves are commonly used in pipelines, where they control the flow of liquids and gases under high-pressure conditions. In power plants, they regulate steam flow and ensure efficient energy production.

Water treatment facilities also benefit from the use of triple offset butterfly valves, where they manage the flow of water and chemicals during treatment processes. Their ability to withstand corrosion makes them ideal for chemical processing applications, effectively handling a wide range of aggressive media.

Conclusion

The triple offset butterfly valve represents an evolution in valve technology, bringing together design innovation and performance efficiency. Its unique offsets contribute to a superior sealing capability, making it an excellent choice for high-pressure and high-temperature applications. As industries continue to seek reliable solutions for fluid control, the triple offset butterfly valve will undoubtedly remain at the forefront, providing safety, efficiency, and longevity in operational capabilities. Whether in oil and gas, power generation, or water treatment, the advantages of this valve type make it a critical component in modern industrial applications.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

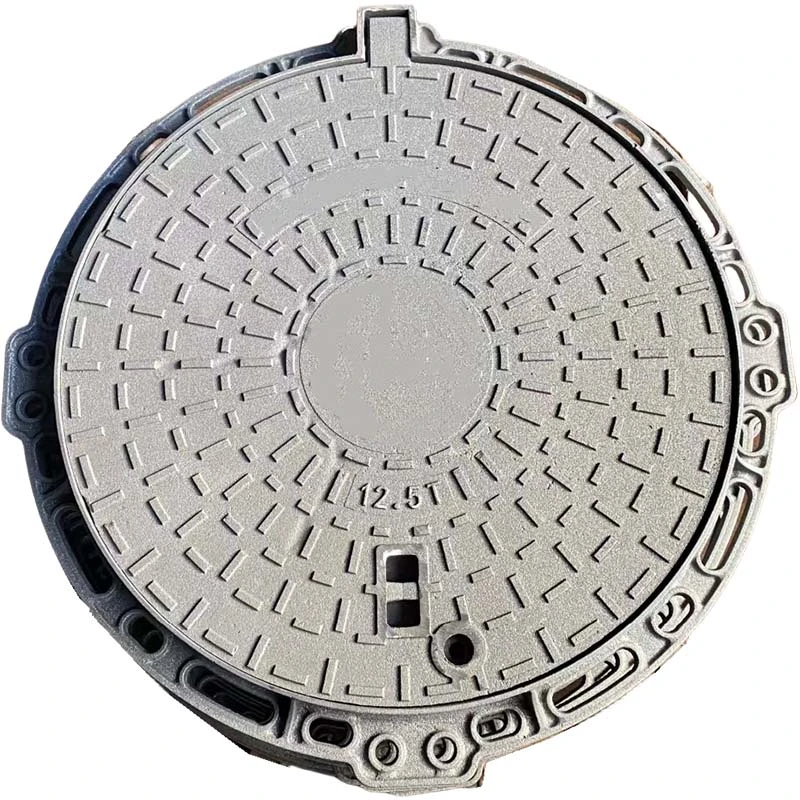

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025