Tight Seal Butterfly Valve for Enhanced Shut Off Performance and Efficiency

Tight Shut Off Butterfly Valve A Comprehensive Overview

In the realm of industrial fluid control systems, the tight shut off butterfly valve has emerged as a pivotal component, providing effective regulation of flow with minimal pressure drop. This article explores the design, functioning, applications, and benefits of tight shut off butterfly valves, highlighting their significant role in modern engineering.

What is a Tight Shut Off Butterfly Valve?

A tight shut off butterfly valve is specifically designed to completely stop the flow of fluid in a pipeline. Unlike standard butterfly valves, which may allow some leakage even in the closed position, a tight shut off butterfly valve ensures a leak-proof seal. It achieves this through the use of advanced sealing materials and mechanisms, allowing for optimal performance in critical applications where preventing leaks is essential.

Design and Components

The tight shut off butterfly valve consists of several key components

1. Disc The disc is a circular element that rotates within the valve body. When the valve is closed, the disc is positioned perpendicular to the flow, blocking it entirely.

2. Seat A critical feature of tight shut off valves is the resilient seat material. Often made from elastomers such as EPDM, Viton, or PTFE, these materials ensure that the valve can create a tight seal when closed.

3. Stem and Actuator The stem connects the disc to a handle or actuator. Manual operation is common, but pneumatic or electric actuators can also be employed for automated control systems, providing rapid response to changes in flow requirements.

4. Body The body of the valve is usually cast in various materials, including stainless steel or carbon steel. The choice of material typically depends on the fluid being controlled and the working conditions, including temperature and pressure.

Working Principle

The operation of a tight shut off butterfly valve is relatively straightforward

. When the valve is opened, the disc is rotated to align with the flow direction, allowing the fluid to pass through with minimal resistance. Conversely, when the valve is closed, the disc rotates 90 degrees to a position that entirely obstructs the flow, forming a tight seal against the seat. This functionality is crucial in many process control applications, where precise flow management is necessary.Applications

tight shut off butterfly valve

Tight shut off butterfly valves are widely utilized across various sectors, including

- Water Treatment Plants Ensuring the efficient management of water flow for purification processes. - Chemical Processing Controlling the flow of corrosive or hazardous chemicals while preventing leaks that could lead to serious safety issues.

- Food and Beverage Industry Maintaining sanitary conditions in processing lines where contamination must be avoided.

- HVAC Systems Regulating airflow in heating, ventilation, and air conditioning systems to improve energy efficiency.

Benefits

The advantages of using tight shut off butterfly valves are numerous

1. Leak Prevention The primary benefit is the ability to prevent leaks, which is critical in many applications, particularly in chemical processing.

2. Space-Saving Design Butterfly valves have a compact design compared to other types of valves, making them ideal for installations with limited space.

3. Flow Efficiency They offer low-pressure drop characteristics, which enhances overall system efficiency and performance.

4. Versatility These valves can handle a wide range of fluids, including gases, liquids, and slurries, making them suitable for diverse applications.

5. Operational Ease Tight shut off butterfly valves can be easily operated manually or automatically, providing flexibility in control systems.

Conclusion

In conclusion, the tight shut off butterfly valve is an essential tool in various industrial applications where controlling flow effectively and preventing leaks is imperative. With their unique design and functional capabilities, these valves contribute significantly to operational efficiencies, safety, and reliability in fluid management. Understanding their features and applications helps engineers and operators make informed decisions, ensuring the integrity and productivity of their systems. As industries continue to evolve, the demand for reliable and efficient flow control solutions like the tight shut off butterfly valve will undoubtedly increase.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

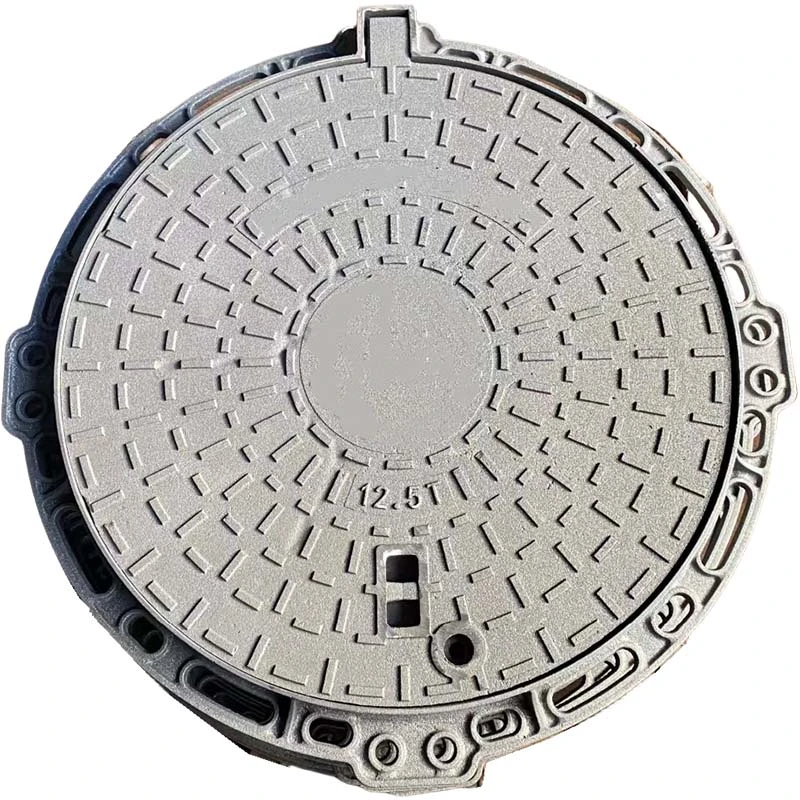

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025