Step Irons: Heavy-Duty, Anti-Slip, Corrosion-Resistant

Plastic-Coated Steps for Manholes: field notes from the trench

If you work around drainage or sewer assets, you already know why step irons matter. They’re the quiet hardware that keeps crews safe when the pit is wet, greasy, or frankly unpleasant. I’ve stood at enough manholes at 6 a.m. to say: details here decide whether a job is routine or risky.

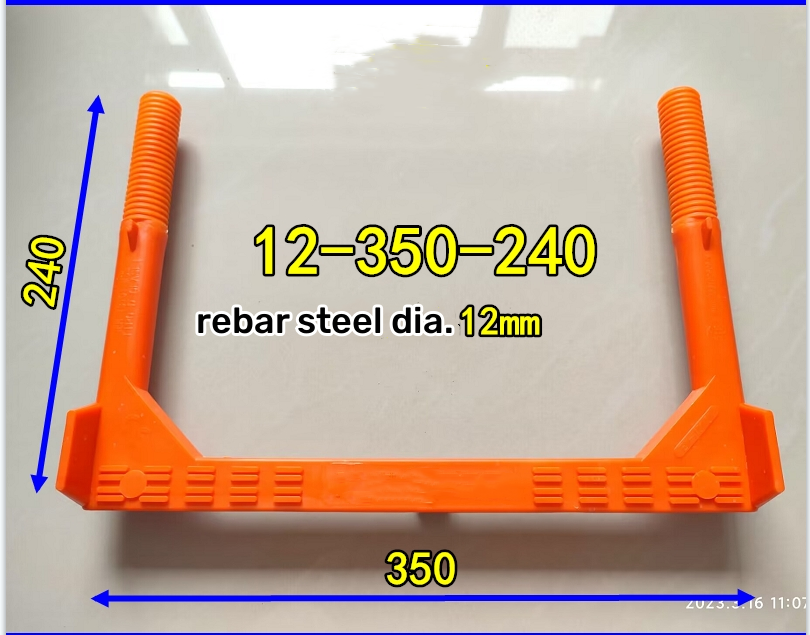

What’s inside the STEP IRONS-PLASTIC COATED

This model uses a high-strength steel core encapsulated in hi‑vis polypropylene (PP). In practice, that means the rigidity of steel and the corrosion resistance of plastic. The rungs are bright for low‑light pits and textured for grip. Many customers say they notice the difference during winter callouts.

Industry trends (short version)

- Shift from bare steel to polymer-encapsulated step irons for longevity and lower life‑cycle cost.

- Stricter adherence to EN 13101 testing; utilities ask for proof, not promises.

- More UV-stabilized pigments; color fade is a maintenance headache people are done with.

Specifications (typical, real-world use may vary)

| Parameter | Spec ≈ | Notes |

|---|---|---|

| Core material | Carbon steel (Q235/Q345) | Deformed or plain bar, per customer preference |

| Coating | PP encapsulation, UV stabilized | Hi‑vis orange/yellow; other colors on request |

| Tread width | ≈ 260–300 mm | Complies with EN 13101 geometry |

| Load test | ≥ 14 kN (pass) | Bending/pull-out tests per EN 13101 |

| Slip resistance | Textured tread | Wet condition tested; grit profile optional |

| Service life | 15–25 years | Assumes typical municipal exposure |

Manufacturing & testing workflow

Materials are cut and bent, then the steel core is cleaned (shot-blast + degrease). Injection encapsulation bonds PP to steel; we’ve seen adhesion peel tests exceed 2.5 N/mm. After curing, each batch faces:

- Geometry check and gauge verification (EN 13101)

- Static load test ≥14 kN and deflection measurement

- UV aging (ISO 4892-2, around 500 h) and impact check (ASTM D256 proxy on coupons)

- Salt spray screening for hardware interfaces (ASTM B117, 96 h)

Applications and advantages

Use step irons in stormwater pits, foul sewers, treatment plants, pump stations, and inspection chambers. Advantages: corrosion resistance, stable footing when the pit is slick, and easy visual inspection. Actually, the biggest win is fewer replacements—utilities dislike confined-space rework.

Vendor comparison (indicative)

| Vendor | Coating | EN 13101 Report | Lead Time ≈ | Notes |

|---|---|---|---|---|

| HB YQ Metal | PP, UV stabilized | Yes (third‑party) | 2–4 weeks | Custom colors, OEM shapes |

| Vendor A | PVC dip | Partial | 3–6 weeks | Budget option |

| Vendor B | EPDM sleeve | Yes | 4–8 weeks | Premium pricing |

Customization, origin, and logistics

Options include color matching (RAL), embossed logos, alternative bar grades, and anti-slip grit. Origin: Room 1005, Building 1-2, Phase I, North China Golden Sun Commercial City, Xinhuanan Road, Xiangdu District, Xingtai City, Hebei Province, China. Certifications: ISO 9001 quality system; EN 13101 compliance reports available; SGS material checks on request.

Field results and feedback

A coastal utility swapped 1,200 step irons during a pump‑station upgrade. After 18 months, inspection logged zero coating delamination and measured color delta E ≈ 1.8 post UV exposure—well below their alert threshold. Another contractor told me installation was “boringly simple,” which is honestly the best compliment for hardware like this.

Standards and safety

Specify step irons to EN 13101 for geometry, load, and slip criteria. For site work, follow confined-space rules and ladder/step access guidance under OSHA 1910 or your local equivalent. If you need the paperwork bundle—test reports, PP datasheets, MSDS—ask early; it speeds approvals.

References

-

Durable & Safe 600mm Round Drain Covers | HBYQ Metal SolutionsNewsNov.25,2025

-

Comprehensive Guide to Square to Round Recessed Drain Cover 500mm | Durable & Efficient Drainage SolutionsNewsNov.24,2025

-

Round to Square Manhole Cover – Adaptive Infrastructure Solutions for Modern CitiesNewsNov.24,2025

-

Square to Round Recessed Drain Cover 450mm – Durable & Efficient Drainage SolutionsNewsNov.23,2025

-

Durable Round Inspection Chamber Covers for Urban and Industrial Use | HBYQ MetalNewsNov.23,2025

-

Square to Round Recessed Drain Cover | Durable & Adaptable Drain SolutionsNewsNov.22,2025

-

Durable Square to Round Recessed Drain Cover 300mm | Reliable Drain SolutionsNewsNov.22,2025