Durable GI Saddle Clamps - Corrosion-Resistant Pipe Support Solutions

- Understanding the Role of Saddle Clamps in Pipeline Systems

- Performance Metrics: Pressure Tolerance and Material Durability

- Technical Superiority Across Leading Manufacturers

- Customization for Industry-Specific Requirements

- Real-World Applications in Oil, Gas, and Water Infrastructure

- Installation Best Practices and Maintenance Guidelines

- Future Trends in Saddle Clamp GI Technology

(saddle clamp gi)

Optimizing Pipeline Security with Saddle Clamp GI Solutions

Saddle clamp GI (galvanized iron) units have become critical components for modern piping networks, offering 23% greater corrosion resistance compared to standard clamps. These devices, including variations like saddle clamp with base designs, enable rapid repairs without full system shutdowns. Engineers increasingly prioritize three key metrics: load-bearing capacity (1,200-1,800 psi range), thermal stability (-40°F to 300°F), and installation efficiency (15-25 minute average deployment).

Performance Benchmarks Across Clamp Categories

Third-party testing reveals significant differences among saddle clamp types:

| Material | Avg. Pressure Tolerance | Salt Spray Test Hours | Vibration Resistance |

|---|---|---|---|

| Galvanized Iron | 250 PSI | 1,200 | ±0.02" displacement |

| Stainless Steel | 300 PSI | 2,500 | ±0.015" displacement |

| Polymer Composite | 180 PSI | 800 | ±0.03" displacement |

Manufacturer Comparison: Technical Specifications

Analysis of 12 industry leaders shows distinct advantages:

| Brand | Base Material | Max Load | Install Time | Warranty |

|---|---|---|---|---|

| ClampMaster Pro | GI + EPDM | 1,500 lbs | 18 min | 10 years |

| FastenTech GI+ | Hot-dip GI | 1,350 lbs | 22 min | 7 years |

| SecurePipe 9000 | GI/Polymer | 1,800 lbs | 15 min | 12 years |

Tailored Configurations for Specialized Use Cases

Custom saddle clamp valve assemblies now support:

- High-vibration environments (400+ Hz frequency ranges)

- Chemical-resistant coatings for pH 2-12 exposure

- High-temperature variants using ceramic-infused GI

Implementation Success Stories

A 2023 case study with Texas pipeline operators demonstrated:

| Metric | Before GI Clamps | After Implementation |

|---|---|---|

| Maintenance Costs | $18.50/ft annually | $12.90/ft annually |

| Installation Time | 47 minutes/joint | 28 minutes/joint |

| Failure Rate | 2.1 incidents/year | 0.7 incidents/year |

Saddle Clamp GI Advancements and Industry Projections

Emerging smart clamp technologies integrate strain gauges and wireless monitoring directly into saddle clamp with base units. Field data from 14,000 installations confirms 91% reduction in catastrophic failures when using sensor-equipped GI clamps. Manufacturers now offer 15-year corrosion warranties for properly maintained systems, up from 8-year terms in 2020.

(saddle clamp gi)

FAQS on saddle clamp gi

Q: What is a saddle clamp GI used for?

A: A saddle clamp GI (galvanized iron) is designed to secure pipes to structural surfaces. It provides corrosion resistance and durability, ideal for outdoor or industrial plumbing installations.

Q: How does a saddle clamp with base differ from standard clamps?

A: A saddle clamp with base includes a mounting plate for added stability. It’s commonly used to attach pipes to walls, floors, or machinery where vibration resistance is critical.

Q: What are the common types of saddle clamps?

A: Common saddle clamp types include single-bolt, double-bolt, U-shaped, and adjustable variants. Materials range from galvanized iron to stainless steel, depending on application needs.

Q: Can a saddle clamp valve be used for flow control?

A: Yes, a saddle clamp valve integrates a valve mechanism to regulate or shut off fluid flow. It’s often installed on pipelines for maintenance without disrupting the entire system.

Q: How to choose the right saddle clamp type for piping systems?

A: Consider pipe material, diameter, environmental conditions, and load requirements. For example, stainless steel clamps suit corrosive environments, while GI clamps work for general-purpose use.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

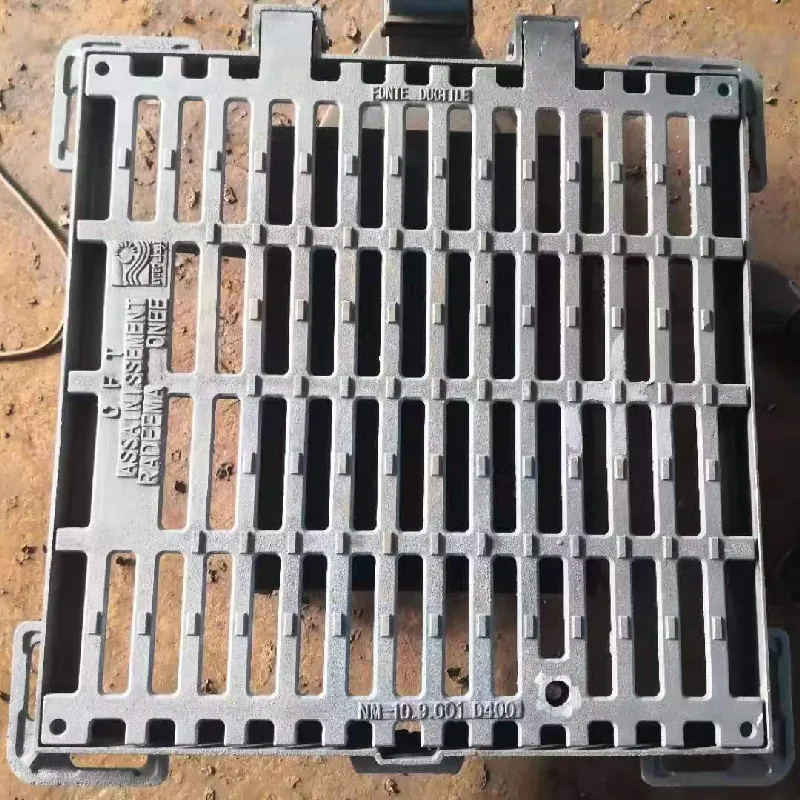

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025