Feb . 11, 2025 04:42

Back to list

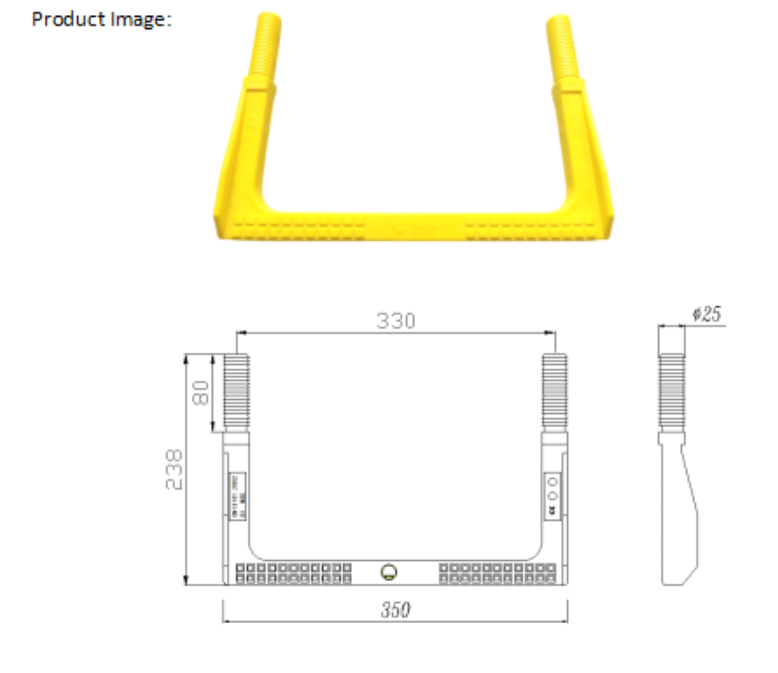

round gully grid

Round gully grid covers are an essential component of modern infrastructure, providing both functional and safety benefits. These covers are ubiquitous in urban settings, where they protect drainage systems and prevent debris from clogging waterways. Their technical design and material composition cater to specific environmental and usage demands, making them versatile and invaluable in our daily lives.

The expertise involved in the creation and implementation of round gully grid covers lies with civil engineers and manufacturers. Civil engineers assess the specific needs of an area, considering factors like climate, traffic load, and urban planning requirements. Meanwhile, manufacturers utilize cutting-edge technology and rigorous testing to produce grid covers that meet stringent safety and quality standards. Authoritativeness in the field of round gully grid covers is established through adherence to international standards, such as those outlined by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). Compliance with these standards ensures that the covers are reliable and safe for public use. Additionally, many manufacturers contribute to research and development in the field, collaborating with academic institutions and industry leaders to innovate new materials and designs. Trustworthiness is built through proven performance over time. Many urban planners and municipalities provide case studies and testimonials that highlight the successful deployment of these covers in various environments. For instance, cities that have implemented comprehensive gully cover systems report a marked reduction in flood incidents and maintenance costs. Trust is also instilled through transparent supply chains; responsible manufacturers ensure traceability of materials and compliance with ethical production practices. In conclusion, round gully grid covers are a testament to engineering excellence, combining functionality, safety, and durability. They stand as a pillar of modern infrastructure, supported by a foundation of experience, expertise, authoritativeness, and trustworthiness. Their continued evolution promises greater resilience and adaptability in the face of changing urban demands, underscoring their importance in safeguarding cities and communities worldwide.

The expertise involved in the creation and implementation of round gully grid covers lies with civil engineers and manufacturers. Civil engineers assess the specific needs of an area, considering factors like climate, traffic load, and urban planning requirements. Meanwhile, manufacturers utilize cutting-edge technology and rigorous testing to produce grid covers that meet stringent safety and quality standards. Authoritativeness in the field of round gully grid covers is established through adherence to international standards, such as those outlined by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). Compliance with these standards ensures that the covers are reliable and safe for public use. Additionally, many manufacturers contribute to research and development in the field, collaborating with academic institutions and industry leaders to innovate new materials and designs. Trustworthiness is built through proven performance over time. Many urban planners and municipalities provide case studies and testimonials that highlight the successful deployment of these covers in various environments. For instance, cities that have implemented comprehensive gully cover systems report a marked reduction in flood incidents and maintenance costs. Trust is also instilled through transparent supply chains; responsible manufacturers ensure traceability of materials and compliance with ethical production practices. In conclusion, round gully grid covers are a testament to engineering excellence, combining functionality, safety, and durability. They stand as a pillar of modern infrastructure, supported by a foundation of experience, expertise, authoritativeness, and trustworthiness. Their continued evolution promises greater resilience and adaptability in the face of changing urban demands, underscoring their importance in safeguarding cities and communities worldwide.

Latest news

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025