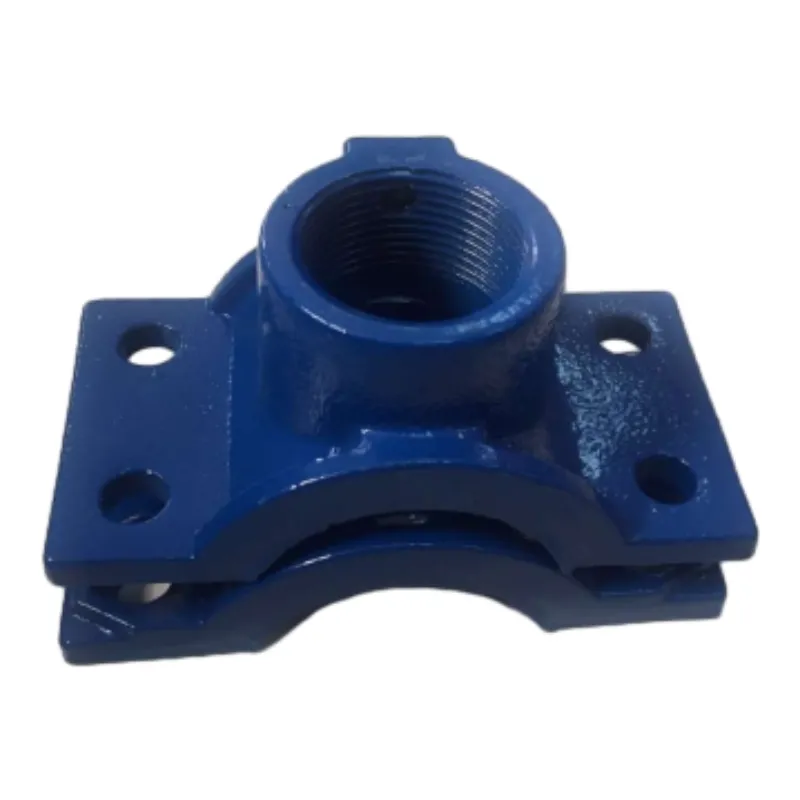

pump air release valve

The Importance and Functionality of Pump Air Release Valves

In various industries, the efficient operation of pumping systems is crucial. Whether it be in water treatment facilities, agricultural irrigation systems, or industrial processes, pumps are designed to move fluids effectively. However, one common issue faced in these systems is the entrapment of air, which can hinder performance and efficiency. This is where pump air release valves (ARVs) come into play. These devices are essential components of fluid transport systems, ensuring optimal operation and safeguarding the equipment involved.

What are Pump Air Release Valves?

Pump air release valves are specialized valves that automatically discharge trapped air from pipelines and pump systems. When a liquid is being pumped, air pockets can form in the pipeline, leading to a phenomenon known as cavitation. Cavitation occurs when the pressure in the fluid drops below the vapor pressure, causing the fluid to vaporize and form bubbles. When these bubbles collapse, they can create shockwaves that can damage pump impellers and other components, leading to costly repairs and down-time in operations.

How Do Pump Air Release Valves Work?

Pump air release valves operate on a simple principle they allow air to escape from the system while preventing the loss of liquid. These valves are typically mounted at high points of a pipeline, where air is likely to accumulate. When air reaches the valve, it opens to release the trapped gas. As soon as the liquid reaches the valve, it closes automatically, effectively sealing the system and preventing leaks.

Most air release valves are equipped with a float mechanism that senses the level of liquid in the valve. When air is present, the float drops, allowing the valve to open. Once the air is expelled and liquid is detected, the float rises, causing the valve to close again. This automatic operation ensures that air is vented without the need for manual intervention, which can be crucial in maintaining continuous flow.

The Benefits of Using Pump Air Release Valves

pump air release valve

1. Improved Efficiency By eliminating trapped air, ARVs ensure that pumps operate at their designed efficiency. This prevents loss of pump performance, reducing energy consumption and operational costs.

2. Extended Equipment Life By preventing cavitation and other air-related issues, these valves help minimize wear and tear on pumps and associated machinery. This can lead to longer service life and decreased maintenance costs.

3. Enhanced Safety Air pockets can create dangerous situations, especially in high-pressure systems. By using pump air release valves, operators can mitigate risks associated with pressure buildups and potential system failures.

4. Reliable Operation The automatic nature of ARVs means that systems can run continuously without requiring constant monitoring for air accumulation. This reliability is crucial for essential services like water treatment and irrigation.

5. Versatility Pump air release valves are available in various sizes and materials, making them suitable for a wide range of applications, from small residential systems to large industrial operations.

Conclusion

In summary, pump air release valves are vital components in ensuring the smooth operation of fluid transport systems. They effectively manage air accumulation, protect against cavitation, and enhance the operational efficiency of pumps. As industries continue to prioritize efficiency and safety, the importance of integrating ARVs into pumping systems cannot be overstated.

By understanding the role and benefits of pump air release valves, operators can make informed decisions about their pumping systems, leading to more reliable and efficient processes. In a world where resource management and operational integrity are critical, these valves represent a simple yet effective solution to a common problem, ultimately contributing to the success of various applications across multiple sectors.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025