Operating Principles of Pneumatically Controlled Butterfly Valves Explained

The Working Principle of Pneumatic Actuated Butterfly Valves

Pneumatic actuated butterfly valves are essential components in many industrial applications, serving as flow control devices that can precisely regulate the passage of liquids and gases. Their design combines mechanical simplicity with effective performance, making them a favored choice in various sectors, including water treatment, oil and gas, food processing, and chemical manufacturing.

Understanding the Butterfly Valve

At its core, a butterfly valve consists of a circular disc or plate—referred to as the 'butterfly'—which rotates around a shaft. The valve is typically housed within a cylindrical body. When the valve is closed, the disc is positioned perpendicular to the flow direction, blocking the passage. When the valve opens, the disc rotates to a parallel position, allowing fluid to flow through. This mechanical simplicity enables rapid opening and closing, making butterfly valves an efficient solution for flow regulation.

The Role of Pneumatic Actuators

Pneumatic actuators serve as the driving force for butterfly valves. These devices use compressed air to create motion. The actuator is connected to the valve stem, and when air is introduced into the actuator, it expands to create movement that turns the valve disc. The incorporation of pneumatic technology allows for quick response times and precise control, which is particularly valuable in processes requiring frequent adjustments or tight regulatory measures.

How It Works

The basic operation of a pneumatic actuated butterfly valve can be broken down into several key steps

1. Air Supply The system requires a source of compressed air. This air should be filtered, regulated, and lubricated to prevent contamination and ensure smooth operation.

pneumatic actuated butterfly valve working

2. Actuation When the control system signals that the valve should either open or close, compressed air is directed into the actuator. The air pressure forces a diaphragm or piston within the actuator to move.

3. Rotation of the Disc This linear motion is converted into rotary motion via a mechanism within the actuator—typically a link connecting the actuator to the valve stem. As the air pressure builds or is released, the valve disc rotates. For opening, the disc turns to a horizontal position; for closing, it turns back to a vertical position.

4. Flow Regulation Depending on the desired flow rate, the angle of the disc can be finely adjusted, enabling varying degrees of openness. Thus, pneumatic actuated butterfly valves can achieve not only full open and closed positions but also intermediate stages for modulating flow.

5. Return to Position Once the desired adjustment is made and air pressure is controlled, the actuator remains at the required position until signaled again. Pneumatic systems can be configured to fail to a safe position in case of an air loss, adding a layer of safety in critical applications.

Advantages and Applications

One of the primary advantages of pneumatic actuated butterfly valves is their efficiency. They require minimal space, have fewer moving parts, and are generally lighter than other valve types, making installation and maintenance easier. Additionally, they can handle a range of pressures and temperatures, which broadens their application scope.

In industries like water treatment, these valves are used for regulating flow rates in treatment processes. In the oil and gas sector, they manage the flow of hydrocarbons through pipelines. They are also found in HVAC systems to control airflow, ensuring optimal energy use and comfort in building environments.

Conclusion

Pneumatic actuated butterfly valves represent a blend of simplicity and efficiency, making them invaluable in numerous industrial applications. Their reliable mechanism and quick actuation capabilities provide unmatched control over fluid dynamics, ensuring that processes run smoothly and efficiently. As industries continue to evolve and embrace automation, the demand for such versatile and effective flow control solutions will undoubtedly increase.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

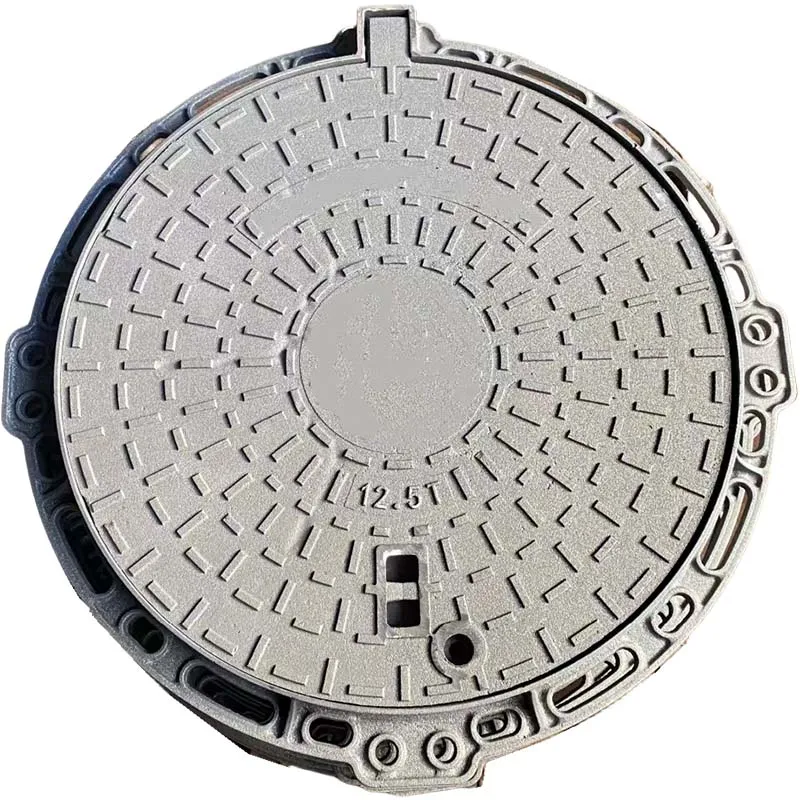

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025