Optimize Bike Storage: Secure & Space-Saving Racks

The Imperative of Robust Bike Storage Solutions in Modern Urban Planning

As urban centers worldwide continue to prioritize sustainable transportation, the demand for efficient and secure bike storage solutions has become paramount. This encompasses everything from individual bicycle racks to large-scale commercial bike racks and integrated bicycle parking facilities. Investing in high-quality bike storage is no longer a luxury but a critical component of infrastructure development, directly impacting rider safety, property security, and urban mobility. For businesses, municipalities, and residential complexes, selecting the appropriate bike storage rack or a comprehensive bike storage solution involves a detailed evaluation of material science, design efficacy, and long-term durability, crucial for supporting eco-friendly transit and enhancing community well-being.

The global bicycle market, valued at approximately USD 60 billion in 2023 and projected to grow at a CAGR of over 7% through 2030, underscores the escalating need for robust bicycle infrastructure. This growth is driven by environmental concerns, health consciousness, and government initiatives promoting cycling. Consequently, the market for effective bike storage solutions is expanding proportionally, demanding innovative and resilient designs that cater to diverse environments, from bustling city centers to corporate campuses and multi-family residential units. Understanding the technical aspects, market trends, and deployment strategies for these solutions is key for B2B stakeholders.

Industry Trends in Advanced Bike Storage

The landscape of bike storage is rapidly evolving, driven by technological advancements and shifting user expectations. Key trends include:

- Smart Bike Storage Systems: Integration of IoT, access control, and digital monitoring for enhanced security and management. This includes app-based booking for locker systems and real-time occupancy data for commercial bike racks.

- Modular and Scalable Designs: Demand for flexible solutions that can be easily expanded or reconfigured to meet changing capacity requirements, from individual bicycle racks to large-scale parking facilities.

- Aesthetic Integration: A growing emphasis on bike storage solutions that complement urban architecture and landscape design, moving beyond purely functional designs to aesthetically pleasing installations.

- Enhanced Security Features: Rise of robust anti-theft designs, including multi-point locking mechanisms, surveillance camera integration, and secure indoor/outdoor bike rack options with reinforced materials.

- Sustainable Materials and Manufacturing: A push towards eco-friendly materials and manufacturing processes that reduce environmental impact while maintaining product durability and service life.

These trends reflect a mature market demanding not just space for bicycles, but comprehensive solutions that integrate security, convenience, and urban aesthetics. The emphasis on durable, low-maintenance materials like stainless steel for outdoor bike rack applications is particularly pronounced due to their exceptional corrosion resistance and longevity.

Technical Specifications and Design Principles for Durable Bike Storage

Effective bike storage solutions are engineered with precise technical specifications to ensure structural integrity, user convenience, and long-term resilience. Key parameters include material composition, load-bearing capacity, corrosion resistance, and specific dimensions for various bicycle types. For commercial and outdoor bike rack applications, material selection is critical, with high-grade stainless steel (e.g., 304, 316) or galvanized steel being preferred for their resistance to environmental stressors.

Key Material and Design Parameters

| Parameter | Description | Typical Specification for Commercial Bicycle Racks |

|---|---|---|

| Material Grade | Type of metal used for structural components. | Stainless Steel 304/316, Galvanized Steel (Hot-dip), Powder-Coated Steel |

| Tubing Diameter | Outer diameter of tubular elements for strength. | Typically 38mm to 60mm (1.5" to 2.375") |

| Wall Thickness | Gauge of the metal tubing for rigidity and security. | 2.5mm to 3.5mm (10 to 12 gauge) |

| Corrosion Resistance | Ability to withstand rust and environmental degradation. | Exceeds ASTM B117 salt spray test for 1000+ hours (for stainless/galvanized) |

| Mounting Options | Methods for securing the rack to the ground or wall. | Surface mount, In-ground/Embedment, Wall mount |

| Security Features | Design elements that deter theft. | U-lock compatible design, fully welded construction, tamper-resistant hardware |

The design of modern bicycle racks also adheres to urban planning guidelines and accessibility standards, ensuring safe and convenient use for all cyclists. This includes optimal spacing between bikes, clear pathways, and ergonomic heights for easy bike maneuvering and locking.

Manufacturing Process for High-Durability Bike Storage Components

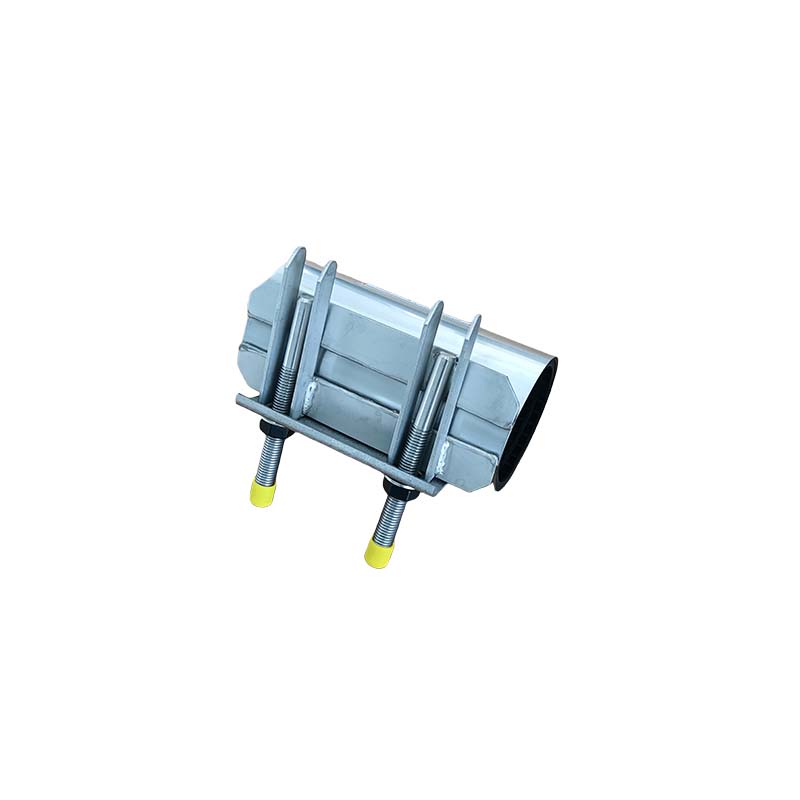

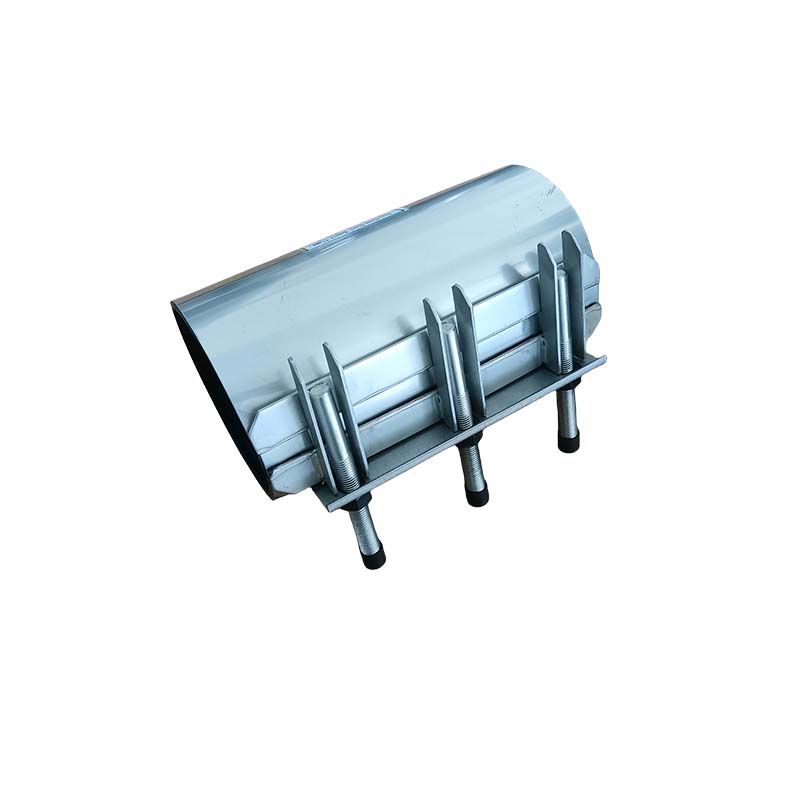

The production of high-performance bike storage components, particularly those crafted from stainless steel for commercial and outdoor applications, demands precision engineering and rigorous quality control. While a complete bike storage system involves assembly, the manufacturing of its individual, durable metal elements relies on processes often found in industries demanding high reliability, such as those that produce specialized repair clamps or pipeline components.

Schematic Process for Stainless Steel Components:

- Material Selection & Preparation: Begins with selecting high-grade stainless steel (e.g., AISI 304, 316) in appropriate forms (sheets, tubes, bars). Material certification ensures compliance with standards like ASTM A240 for stainless steel.

- Cutting & Shaping: Precision cutting (laser, plasma, or saw cutting) of raw materials to specified dimensions. This is followed by forming processes such as bending, rolling, or pressing to achieve the desired rack profiles and structural elements. For intricate parts or mounting brackets, CNC machining ensures tight tolerances.

- Welding & Assembly: Components are joined using advanced welding techniques (e.g., TIG, MIG) to create robust, seamless connections. Full penetration welds are critical for structural integrity, especially in outdoor bike rack designs.

- Surface Treatment & Finishing: Depending on the aesthetic and environmental requirements, components undergo processes like passivation (for stainless steel to enhance corrosion resistance), electropolishing, or powder coating (for added durability and color). This step is crucial for the long service life of an outdoor bike rack.

- Quality Control & Testing: Each batch undergoes stringent quality checks, including dimensional inspection, material strength verification, and visual inspection for defects. For critical applications, non-destructive testing (NDT) such as ultrasonic or radiographic testing might be employed to ensure weld integrity. These components are subjected to testing standards such as ISO 9001 for quality management and ANSI standards for product performance, similar to the rigorous testing applied to a stainless steel single band repair clamp.

- Packaging & Delivery: Finished components are carefully packaged to prevent damage during transit and delivered for final assembly into complete bike storage solutions.

The emphasis on corrosion resistance and extended service life is paramount. Materials and processes are chosen to ensure products can withstand harsh environments for decades. While target industries like petrochemicals or water supply & drainage might utilize specialized repair clamps for pipe integrity, the underlying principles of material science, precision manufacturing, and adherence to international standards (e.g., ISO, ANSI) for durability and reliability are directly transferable to high-quality metal components for commercial bike storage. This ensures that even in demanding outdoor urban settings, these solutions maintain their structural integrity and aesthetic appeal, offering energy saving benefits through reduced maintenance and replacement cycles.

Application Scenarios for Bike Storage Solutions

Versatile bike storage solutions are essential across a multitude of public and private sectors, addressing diverse needs for secure and accessible bicycle parking. From high-traffic urban areas to specialized industrial complexes, the deployment of appropriate bicycle racks and storage systems is tailored to specific user groups and environmental conditions.

- Commercial & Retail Spaces: Shopping malls, business parks, and retail outlets implement commercial bike racks to attract environmentally conscious customers and employees, often integrating them into facade design or dedicated parking zones.

- Educational Institutions: Universities, colleges, and schools require extensive bike storage solutions to accommodate large student populations, with a mix of outdoor bike rack styles and secure bike shelters.

- Public Transit Hubs: Train stations, bus terminals, and ferry ports utilize high-capacity bicycle racks and bike lockers to support multi-modal commuting, enabling seamless transitions between cycling and public transport.

- Residential Developments: Multi-family housing, apartment complexes, and condominiums offer secure indoor or outdoor bike rack options as a key amenity, enhancing property value and resident satisfaction.

- Healthcare Facilities: Hospitals and clinics provide bike storage for staff, patients, and visitors, promoting active living and reducing parking demand.

- Parks & Recreation Areas: Public parks and recreational facilities install durable outdoor bike rack solutions to support visitors arriving by bicycle, often prioritizing aesthetic integration with natural landscapes.

Each scenario demands tailored solutions, considering factors such as security level, capacity, weather protection, and visual impact. The ability to deploy a robust, long-lasting outdoor bike rack that withstands heavy usage and vandalism is critical across all these applications.

Technical Advantages of Premium Bike Storage Systems

Investing in premium bike storage solutions delivers significant technical and operational advantages for B2B clients:

- Superior Durability and Longevity: Manufactured from high-grade materials like stainless steel or galvanized steel, these systems offer exceptional resistance to corrosion, impact, and wear, ensuring a service life of 15+ years even in harsh outdoor conditions. This minimizes replacement costs and maintenance.

- Enhanced Security: Designs specifically engineered to deter theft, featuring robust frame construction, tamper-resistant mounting hardware, and compatibility with various locking mechanisms (e.g., U-locks, chain locks). Secure bicycle racks reduce liability and enhance user trust.

- Space Optimization: Innovative designs, such as two-tier bike racks or vertical storage solutions, maximize parking density, allowing for a higher capacity of bikes in a smaller footprint – critical for urban environments.

- Low Maintenance Requirements: The inherent properties of materials like stainless steel reduce the need for frequent cleaning or repainting, contributing to lower operational costs over the product's lifespan.

- Aesthetic Value and Urban Integration: Modern bike storage solutions are designed to be visually appealing, seamlessly blending into architectural contexts and enhancing the overall streetscape or facility aesthetics.

- Compliance with Standards: Adherence to international and local standards (e.g., AASHTO, APBP guidelines) for spacing, accessibility, and structural integrity ensures universal usability and regulatory compliance.

These advantages translate into a higher return on investment (ROI) for organizations, through reduced operating expenses, enhanced user experience, and a positive contribution to corporate social responsibility (CSR) initiatives by promoting sustainable transport.

Vendor Comparison: Evaluating Bike Storage Providers

Choosing the right vendor for commercial bike storage solutions requires a comprehensive evaluation beyond initial cost. Key differentiators include material quality, design innovation, manufacturing capabilities, and after-sales support. Below is a comparative overview of typical vendor profiles:

Product Comparison: Standard vs. Premium Bicycle Racks

| Feature | Standard Bike Rack | Premium Commercial Bike Rack |

|---|---|---|

| Material | Powder-coated Mild Steel | Stainless Steel 304/316, Hot-dip Galvanized Steel |

| Corrosion Resistance | Good (requires recoating over time) | Excellent (inherent, maintenance-free) |

| Security Features | Basic U-lock compatibility, bolted assembly | Robust fully welded construction, tamper-resistant, multiple locking points |

| Service Life (Outdoor) | 5-10 years (with maintenance) | 15-25+ years (minimal maintenance) |

| Installation | Generally straightforward | Engineered for precise, secure installation (surface or embedment) |

| Certification/Compliance | Basic (if any) | ISO 9001, LEED eligibility, APBP guidelines |

Authoritative sources like the Association of Pedestrian and Bicycle Professionals (APBP) provide valuable guidelines for effective bike parking. Reputable vendors often hold ISO certifications for quality management and have extensive portfolios demonstrating their expertise and experience. Partnering with a vendor offering customized solutions, a strong warranty, and reliable customer support is crucial for long-term satisfaction.

Customized Bike Storage Solutions

Many projects demand bike storage solutions that go beyond off-the-shelf products. Customization allows for perfect integration with specific architectural styles, urban landscapes, or unique site constraints. This can involve:

- Tailored Dimensions: Modifying bicycle rack lengths, heights, or spacing to fit unusual spaces or accommodate specialized bikes (e.g., cargo bikes, recumbents).

- Bespoke Aesthetics: Incorporating custom finishes, colors, branding, or unique structural forms that align with an organization's identity or a specific design vision.

- Integrated Features: Adding integrated lighting, digital displays, charging stations for e-bikes, or specialized security systems directly into the bike storage design.

- Material Adaptation: Utilizing specific materials or coatings required for extreme environmental conditions (e.g., coastal areas with high salt exposure) or for compliance with stringent local regulations.

Expert providers offer design consultation, CAD drawings, and prototype development to ensure the customized solution meets all functional, aesthetic, and regulatory requirements. This collaborative approach ensures that the final bicycle racks are not only functional but also contribute positively to the built environment.

Application Case Studies

Real-world implementations demonstrate the tangible benefits of well-designed bike storage:

Case Study 1: Urban Transit Hub Redevelopment

Client: Major Metropolitan Transit Authority

Challenge: Accommodate a projected 300% increase in bicycle commuters at a newly renovated rail station, requiring high-capacity, secure, and weather-protected outdoor bike rack solutions that integrate seamlessly with the modern architectural design.

Solution: Installation of 150 two-tier bicycle racks fabricated from polished 316 stainless steel, chosen for its superior corrosion resistance and sleek appearance. The design included integrated LED lighting and smart access control for dedicated bike parking shelters. The system's modularity allowed for phased expansion as demand grew.

Outcome: Bicycle ridership increased by 250% within two years, exceeding initial projections. User feedback cited high satisfaction with security and ease of use. The durable materials ensured minimal maintenance, even in a high-traffic urban environment, significantly extending the service life.

Case Study 2: Corporate Campus Expansion

Client: Global Technology Firm, Silicon Valley Campus

Challenge: Provide secure and visually appealing bike storage for over 500 employees, encouraging active commuting while reflecting the company's commitment to sustainability and innovation.

Solution: A distributed network of custom-designed bicycle racks and secured bike lockers throughout the campus. Outdoor racks utilized hot-dip galvanized steel with a custom powder-coat finish matching brand colors, while indoor facilities featured individual bike lockers with electronic access. Over 70% of the racks were located under covered structures to offer additional weather protection.

Outcome: Employee cycling rates increased by 40%, reducing reliance on car parking and contributing to the company's LEED certification efforts. The robust construction and thoughtful design of the outdoor bike rack systems resulted in zero reported bike thefts over a five-year period, fostering a trusting and positive employee experience.

Frequently Asked Questions (FAQ)

- Q: What is the recommended material for outdoor bike rack installations?

- A: For maximum durability and corrosion resistance in outdoor environments, we recommend either 304 or 316 grade stainless steel, or hot-dip galvanized steel. These materials offer superior longevity and require minimal maintenance compared to standard painted mild steel.

- Q: How do your bike storage solutions ensure security?

- A: Our commercial bike racks are designed with U-lock compatibility, featuring robust frame construction and fully welded joints to prevent tampering. We also offer secure locker systems with advanced locking mechanisms and options for integrated surveillance.

- Q: Can your bicycle racks be customized to match specific architectural designs?

- A: Yes, we specialize in customized solutions. We can adapt dimensions, finishes, colors, and integrate specific branding or design elements to ensure seamless integration with your project's aesthetic and functional requirements.

- Q: What are the typical lead times for large-scale bike storage projects?

- A: Lead times vary depending on the scale and complexity of the order, particularly for customized solutions. For standard products, manufacturing and delivery typically range from 4-6 weeks. Custom projects may require 8-12 weeks for design, fabrication, and delivery. We provide detailed timelines upon project consultation.

Fulfillment, Warranty, and Customer Support

Our commitment to client satisfaction extends through every stage of the project lifecycle for your bike storage needs:

- Lead Time & Fulfillment: We maintain efficient manufacturing processes and a robust supply chain to ensure timely project completion. Standard orders are typically fulfilled within 4-6 weeks, while complex customized solutions are delivered within a mutually agreed upon timeframe, generally 8-12 weeks. Detailed project schedules are provided at the outset.

- Warranty Commitment: All our commercial bike racks and storage systems come with a comprehensive warranty against defects in material and workmanship. For stainless steel and galvanized steel products, we offer an industry-leading 15-year warranty, reflecting our confidence in product durability and longevity. Specific warranty terms are outlined in our contracts.

- Customer Support & After-Sales Service: Our dedicated customer support team is available to assist with technical queries, installation guidance, and any post-purchase requirements. We provide detailed installation manuals and offer expert advice to ensure seamless deployment and optimal performance of your bike storage infrastructure.

Our goal is to provide reliable, high-performance bike storage solutions backed by exceptional service, building long-term partnerships with our B2B clients.

References

- Grand View Research. (2023). Bicycle Market Size, Share & Trends Analysis Report By Product Type (Electric, Conventional), By Distribution Channel (Offline, Online), By Region, And Segment Forecasts, 2023 - 2030.

- Association of Pedestrian and Bicycle Professionals (APBP). (2015). Bicycle Parking Guidelines: Second Edition.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 - Quality management systems — Requirements.

- ASTM International. (2021). ASTM A240/A240M-21 - Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications.

-

Durable & Safe 600mm Round Drain Covers | HBYQ Metal SolutionsNewsNov.25,2025

-

Comprehensive Guide to Square to Round Recessed Drain Cover 500mm | Durable & Efficient Drainage SolutionsNewsNov.24,2025

-

Round to Square Manhole Cover – Adaptive Infrastructure Solutions for Modern CitiesNewsNov.24,2025

-

Square to Round Recessed Drain Cover 450mm – Durable & Efficient Drainage SolutionsNewsNov.23,2025

-

Durable Round Inspection Chamber Covers for Urban and Industrial Use | HBYQ MetalNewsNov.23,2025

-

Square to Round Recessed Drain Cover | Durable & Adaptable Drain SolutionsNewsNov.22,2025

-

Durable Square to Round Recessed Drain Cover 300mm | Reliable Drain SolutionsNewsNov.22,2025