Metal-to-metal seated butterfly valves for reliable industrial applications and performance optimization

Metal-to-Metal Seated Butterfly Valves An Overview

Butterfly valves are crucial components in various industrial processes, often used to control the flow of fluids in a piping system. Among the different types of butterfly valves, metal-to-metal seated butterfly valves stand out due to their durability, reliability, and suitability for high-pressure applications. This article discusses the features, applications, advantages, and considerations regarding metal-to-metal seated butterfly valves.

Features of Metal-to-Metal Seated Butterfly Valves

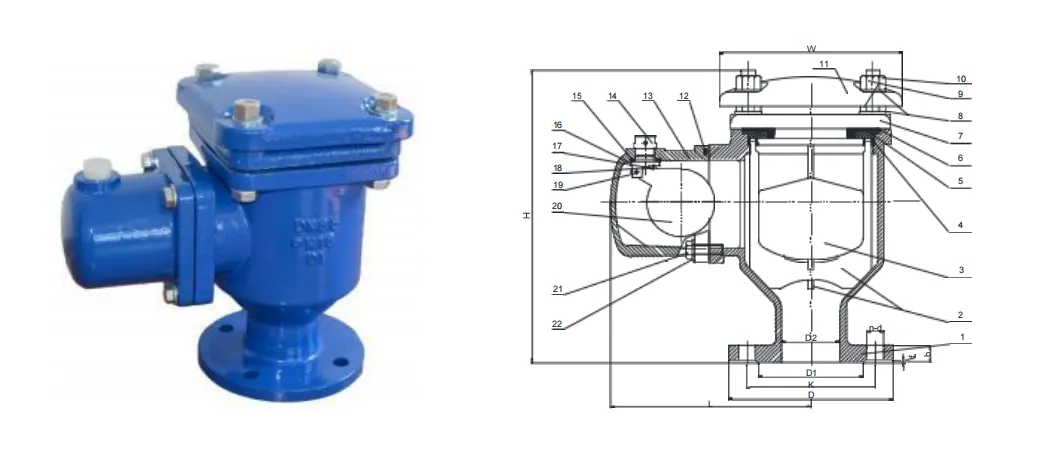

Metal-to-metal seated butterfly valves feature a disc that rotates around a shaft. When the valve is closed, the disc seats tightly against a metal surface, creating a seal that prevents flow. The contact between the metal surfaces allows these valves to handle higher temperatures and pressures compared to their soft-seated counterparts. Typically, the body of these valves is made from robust materials such as carbon steel, stainless steel, or alloy steels, which enhance their performance and longevity.

One significant feature of metal-to-metal seated valves is their ability to handle a diverse range of fluids, including corrosive and abrasive materials. The design also minimizes the risk of leakage, ensuring efficient and safe operation in various industrial applications.

Applications of Metal-to-Metal Seated Butterfly Valves

These valves are widely used across multiple industries, including

1. Oil and Gas Industry Metal-to-metal seated butterfly valves are prevalent in the oil and gas sector due to their ability to handle high pressures and corrosive environments.

2. Chemical Processing In chemical plants, these valves ensure reliable flow control and sealing of hazardous materials.

3. Water Treatment They are often employed in water treatment facilities for regulating water flow, where durability and resistance to corrosive elements are essential.

4. Power Generation The thermal power sector utilizes these valves in steam and water applications, where high temperature and pressure resistance is required.

5. Mining In mining operations, the ability to handle slurries, abrasives, and viscous fluids makes these valves particularly useful.

Advantages of Metal-to-Metal Seated Butterfly Valves

1. Durability The metal-to-metal seating provides superior strength and resistance to wear and tear, allowing for longer service life even in demanding conditions.

metal to metal seated butterfly valves

2. High Pressure and Temperature Resistance These valves can operate efficiently in high-pressure and high-temperature environments, making them suitable for extreme industrial applications.

3. Reduced Maintenance The robust design and materials reduce the need for frequent maintenance, resulting in lower operational costs.

4. Leak Tightness The precision engineering of metal-to-metal seating ensures minimal leakage, which is critical in industries dealing with hazardous substances.

5. Versatility Available in various sizes and configurations, these valves can be customized to fit specific application needs.

Considerations When Choosing Metal-to-Metal Seated Butterfly Valves

While metal-to-metal seated butterfly valves offer numerous advantages, certain considerations should be accounted for during selection

1. Operating Conditions Assessing the specific operating conditions such as pressure, temperature, and the nature of the fluid is essential for ensuring compatibility.

2. Sizing Proper sizing is crucial for achieving optimal performance. An undersized valve may lead to pressure drops, while an oversized valve may result in inefficient flow control.

3. Cost While initial costs may be higher compared to other valve types, the long-term savings from reduced maintenance and replacement costs should be considered.

4. Installation Proper installation is crucial for maximizing the performance and lifespan of the valve. Consulting with experienced professionals during installation can ensure that the valve functions as intended.

5. Regulatory Compliance In many industries, valves must meet specific regulatory standards. It's critical to ensure that the selected butterfly valve complies with relevant industry standards.

Conclusion

Metal-to-metal seated butterfly valves are a robust and reliable solution for controlling fluid flow in various industrial applications. Their durability, high-pressure resistance, and low maintenance make them an excellent choice for challenging environments. For industries requiring efficient, leak-tight solutions, investing in quality metal-to-metal seated butterfly valves can lead to significant operational benefits and cost savings over time.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025