MDPE Pipe Repair Solutions for Quick and Effective Infrastructure Maintenance and Management

MDPE Pipe Repair Clamps A Comprehensive Overview

In the field of plumbing and civil engineering, the integrity of pipeline systems is crucial for ensuring the efficient delivery of water and other fluids. One common type of pipeline material is Medium-Density Polyethylene (MDPE), known for its durability, flexibility, and resistance to various chemicals. However, just like any material, MDPE pipes can develop leaks or suffer from damages due to environmental factors or mechanical impacts. In such instances, the use of MDPE pipe repair clamps becomes essential for quick and effective repairs.

Understanding MDPE Pipes

MDPE pipes are widely used for gas and water distribution systems, primarily because of their robust nature and ability to withstand pressures and temperature variations. They are lightweight, making transportation and installation easier compared to traditional materials such as steel or concrete. However, factors like ground movement, installation errors, or external forces can lead to pipe failures, necessitating efficient repair methods.

What Are MDPE Pipe Repair Clamps?

MDPE pipe repair clamps are specialized devices designed to provide a temporary or permanent solution for damaged MDPE pipes. They work by surrounding the damaged area and applying pressure to seal the leak, preventing further fluid loss and reducing the risk of environmental contamination. These clamps come in various sizes and configurations to accommodate different pipe diameters and damage types.

Types of MDPE Pipe Repair Clamps

1. Standard Repair Clamps Typically made from stainless steel, these clamps are bolted around the pipe to provide a secure seal. They are effective for small cracks or pinhole leaks.

2. Split Repair Clamps These can be installed without needing to remove the damaged section of the pipe. They are particularly useful in situations where access is limited.

3. Heavy-Duty Clamps Designed for larger leaks or more substantial pipe damage, these clamps can handle significant pressure and strain, making them ideal for industrial applications.

mdpe pipe repair clamp

4. Flexible Repair Clamps These clamps consist of a flexible rubber material that conforms to the shape of the pipe, providing a tight seal even in instances where the pipe has deformed.

Installation Process

Installing an MDPE pipe repair clamp is relatively straightforward but requires attention to detail. Here are the general steps involved

1. Assess the Damage Before applying a clamp, inspect the pipe thoroughly to determine the extent of the damage.

2. Clean the Area Clear any dirt, debris, or corrosion from the damaged section to ensure a proper seal.

3. Choose the Correct Size Clamp Selecting the right clamp size is critical for effective sealing. Measure the diameter of the pipe and choose a compatible clamp model.

4. Position and Secure the Clamp Place the clamp over the damaged area and tighten it according to the manufacturer's instructions. Ensure that it evenly distributes pressure around the pipe.

5. Test the Repair After installation, re-pressurize the pipe and check for leaks to confirm the effectiveness of the repair.

Conclusion

MDPE pipe repair clamps are invaluable tools in maintaining the functionality of pipeline systems. Their effectiveness in sealing leaks and preventing further damage provides an economical and efficient solution for both temporary and permanent repairs. With a variety of clamp types available, it is essential to choose the right one based on the specific requirements of the repair situation. Timely repairs using MDPE pipe repair clamps not only extend the life of the pipeline but also contribute to ensuring the safety and reliability of water and gas distribution systems.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

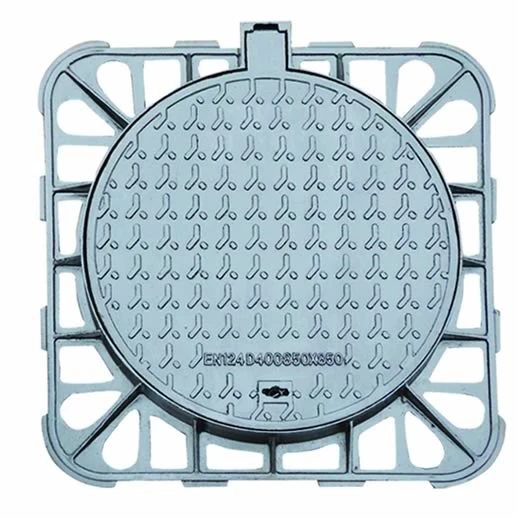

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025