manual relief valve

Understanding Manual Relief Valves Function, Design, and Importance

Manual relief valves are crucial components in various industrial applications, designed to manage the pressure within systems and ensure safe operation. Unlike automatic relief valves, which operate without human intervention, manual relief valves require an operator to open or close them, allowing direct control over the pressure release process. This article will explore the function, design, and significance of manual relief valves in modern engineering.

Functionality of Manual Relief Valves

The primary function of a manual relief valve is to prevent system overpressure, which can cause equipment damage, pose safety hazards, and lead to costly downtimes. These valves facilitate the immediate release of excess pressure, ensuring that the system operates within its designated pressure limits.

In specific situations, operators must intervene to relieve pressure manually, such as during maintenance or when an unexpected pump surge occurs. By enabling a controlled release, manual relief valves safeguard equipment and personnel while maintaining optimal system performance.

Design Aspects

Manual relief valves come in various designs and configurations, tailored to meet specific operational requirements. Key design features include

1. Body Construction The material of the valve body must be compatible with the fluid being controlled. Common materials include stainless steel, brass, and various alloys that can withstand high pressure and corrosive environments.

2. Actuation Mechanism The valve has a lever or handwheel that allows the operator to manually open or close the valve. This simple mechanism provides direct feedback to the operator and ensures effective pressure management.

3. Size and Flow Rate Manual relief valves are designed to accommodate different sizes and flow rates, depending on the application's needs. Choosing the right size is crucial for maintaining proper system functionality and safety.

manual relief valve

4. Sealing and Pressure Settings The sealing mechanisms within the valve must be reliable to prevent leaks during operation. Additionally, the pressure settings should be adjustable to accommodate various operational parameters.

5. Safety Features Many manual relief valves are equipped with safety features such as pressure gauges that provide real-time feedback on system pressure. These features enhance operator awareness and contribute to safe operations.

Importance in Industry

The significance of manual relief valves can be seen across multiple industrial sectors, including manufacturing, oil and gas, chemical processing, and power generation. In these industries, the consequences of pressure imbalances can be catastrophic, leading to equipment failure, environmental spills, and even loss of life.

1. Safety Compliance Regulations in many industries mandate the use of pressure-relief devices. Manual relief valves help companies adhere to safety standards, minimizing liability and fostering a culture of safety.

2. Operational Efficiency By allowing operators to manage pressure levels effectively, manual relief valves contribute to operational efficiency. They help maintain optimal conditions within systems, reducing the risk of unexpected shutdowns and ensuring consistent production levels.

3. Maintenance and Troubleshooting Manual relief valves play a critical role during maintenance and troubleshooting. They enable technicians to safely release pressure and perform necessary repairs without risking injuries or damage to the system.

4. Cost-Effectiveness While manual relief valves require initial investment and regular maintenance, they ultimately save costs by preventing damage to systems and minimizing downtime. A well-maintained manual relief valve can enhance the longevity and efficiency of the equipment.

Conclusion

In summary, manual relief valves are essential components that provide crucial safety and operational benefits across various industries. Their ability to manage pressure manually allows for flexibility in operation and maintenance, protecting both personnel and equipment. Understanding the functionality and design of these valves is vital for engineers and operators alike, ensuring that they are integrated effectively into safety protocols and operational practices. As industries continue to evolve, the role of manual relief valves will remain significant, contributing to safer and more efficient manufacturing processes.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

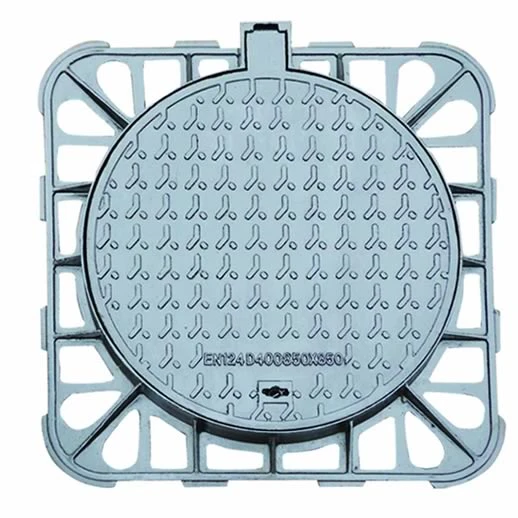

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025