High Efficiency Double Offset Butterfly Valve for Enhanced Performance and Reliability

High Performance Double Offset Butterfly Valve A Comprehensive Overview

In the realm of industrial fluid control, valves play a critical role in managing the flow of liquids and gases. Among these, the high-performance double offset butterfly valve has gained recognition for its efficiency, versatility, and reliability. This article delves into the design, functionality, applications, and advantages of the double offset butterfly valve, emphasizing its importance in modern engineering.

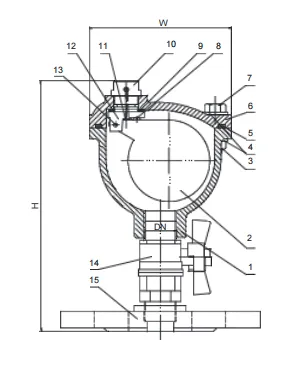

Design and Construction

The high-performance double offset butterfly valve is characterized by two key offsets the first is the offset of the valve shaft from the centerline of the disc, and the second is the offset of the disc from the valve body. This innovative design allows for a more efficient sealing mechanism compared to traditional concentric butterfly valves. The valve is generally constructed from high-quality materials such as stainless steel, carbon steel, or other alloys, making it suitable for various application environments, including high-pressure and high-temperature scenarios.

Functionality

The operation of a double offset butterfly valve is relatively straightforward. When the valve is fully closed, the disc makes contact with the seat, creating a tight seal that prevents leakage. As the valve is opened, the disc rotates around its axis, pivoting away from the seat. The double offset design minimizes the friction between the disc and the seat, which not only enhances the valve’s lifespan but also allows for smoother operation. This design feature ensures that the disc does not remain in contact with the seat during the full opening cycle, reducing wear and tear.

Applications

High-performance double offset butterfly valves are widely used across various industries, including oil and gas, water treatment, chemical processing, HVAC systems, and power generation. Their ability to provide reliable flow control makes them suitable for both on/off and throttling applications. Whether managing the flow of corrosive chemicals or controlling water distribution in municipal systems, these valves offer performance that meets stringent industry standards.

high performance double offset butterfly valve

Advantages

1. Low Pressure Drop One of the most significant advantages of the double offset butterfly valve is its design, which ensures minimal pressure drop across the valve. This feature is particularly crucial in systems where maintaining pressure is essential for operational efficiency.

2. Tight Sealing The unique sealing mechanism of the double offset design allows for a tight seal when the valve is closed. This feature significantly reduces leakage risk, making it ideal for applications involving hazardous or costly fluids.

3. Durability and Reliability Constructed from robust materials and designed to withstand harsh operating conditions, these valves are built for longevity. Their resistance to corrosion and wear ensures reliable performance over extended periods, contributing to lower maintenance costs.

4. Ease of Operation With various actuation options available, including manual, pneumatic, and electric, double offset butterfly valves offer flexibility in operation. This adaptability allows operators to integrate them easily into existing systems, enhancing overall productivity.

5. Compact Design The space-saving design of these valves is another notable benefit. They require less space compared to traditional gate or globe valves, making them suitable for installations where space is limited.

Conclusion

The high-performance double offset butterfly valve represents a significant advancement in valve technology, offering a robust solution for various fluid control applications. Its unique design features, combined with numerous advantages such as low pressure drop, tight sealing, and durability, make it an ideal choice for many industries. As technology continues to evolve, the demand for reliable and efficient fluid control solutions will only grow, and the double offset butterfly valve is well-positioned to meet these emerging needs. Whether in critical infrastructure or everyday industrial processes, this valve type proves its worth time and again, standing as a testament to engineering excellence in fluid management.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025