Jan . 26, 2025 01:44

Back to list

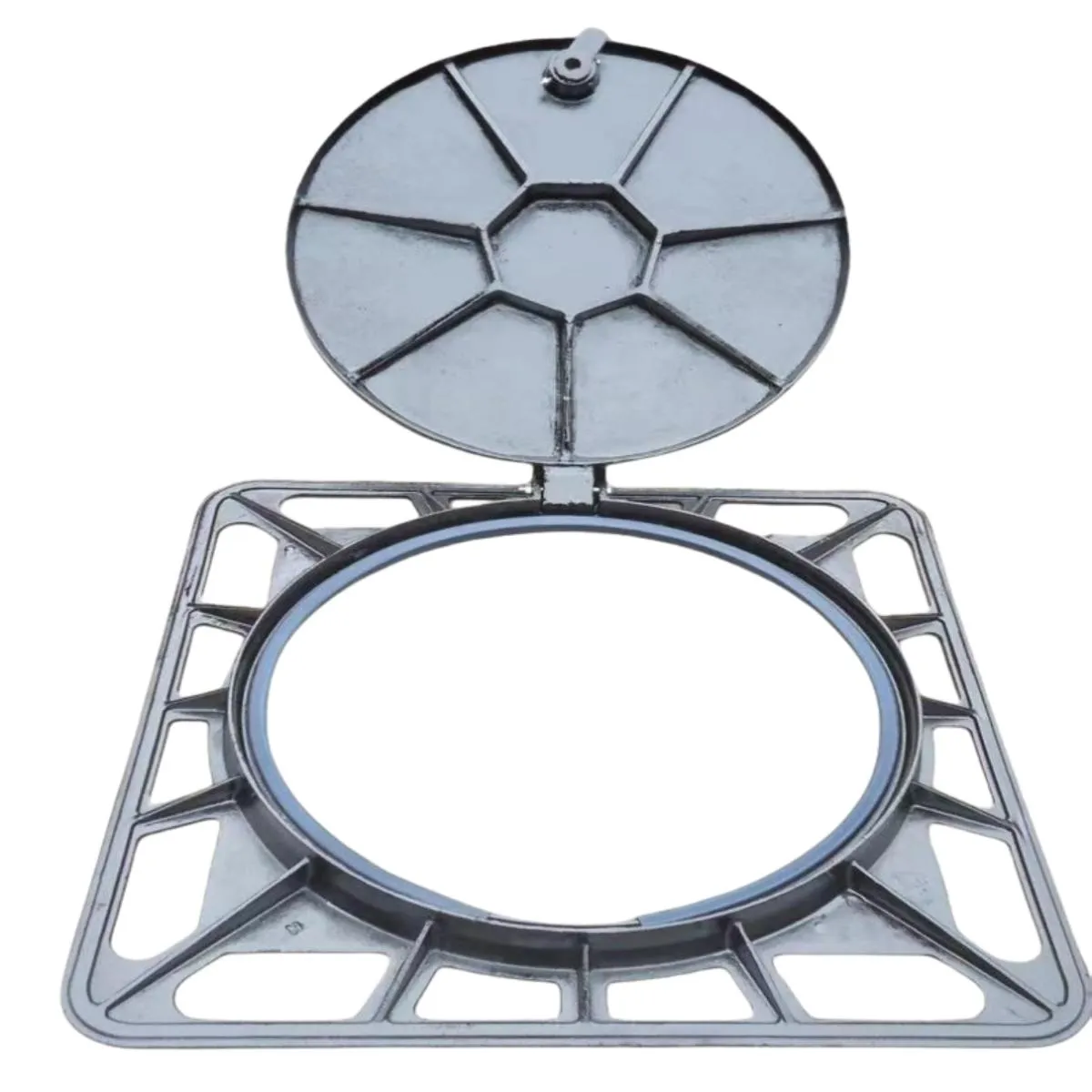

Galvanized Mild Steel Trench Road Gully Grate & frame C250 Standard

The gully grid drain cover, often overlooked in the grand scheme of urban infrastructure, serves as a silent yet essential guardian of our cities' drainage systems. This seemingly modest component plays a crucial role in ensuring our roadways, sidewalks, and public spaces remain free from flooding and water accumulation. The expertise behind its design and installation reflects a high level of engineering and urban planning sophistication.

When selecting a drain cover for a specific application, consider environmental factors, anticipated load, installation site characteristics, and local weather patterns. Regions with heavy rainfall or snowfall, for example, may require covers with anti-slip surfaces or enhanced drainage efficiency. Coastal areas might prioritize corrosion-resistant materials to combat the effects of saltwater. Consulting with an experienced civil engineer or urban planner is advisable to ensure that the chosen solution is both effective and sustainable. In practical terms, installing a gully grid drain cover involves intricate coordination. The installation team must assess the subsurface conditions, verifying that there are no underlying obstructions or vulnerabilities that might undermine the drain cover during extreme weather conditions. A precise fit is essential, as any misalignment could result in compromised drainage efficiency or increased maintenance demands. Authoritativeness in the industry is often demonstrated by market leaders who produce gully grid drain covers. Companies with decades of experience typically offer superior design and innovation, as well as a depth of knowledge in meeting diverse urban infrastructure challenges. Their extensive research and development efforts are pivotal in advancing this niche of urban development, introducing new materials and technologies that enhance both performance and environmental sustainability. Moreover, maintaining public safety and infrastructure integrity underlines the importance of installing reliable drain covers. An unfit or poorly installed drain cover could pose hazards such as trip and fall accidents, infrastructure damage, or flood risks. Regular maintenance checks, timely replacements, and adherence to safety guidelines play a vital role in upholding the longevity and functionality of these vital urban assets. In conclusion, the gully grid drain cover is far more than a mere utility component; it is an embodiment of engineering prowess, urban planning expertise, and manufacturing excellence. While the public may take these underground guardians for granted, the professionals behind their production and installation understand their substantial impact on enhancing urban living conditions. Trust in their dependability and commitment to quality ensures that cities function smoothly, no matter the weather or urban demand.

When selecting a drain cover for a specific application, consider environmental factors, anticipated load, installation site characteristics, and local weather patterns. Regions with heavy rainfall or snowfall, for example, may require covers with anti-slip surfaces or enhanced drainage efficiency. Coastal areas might prioritize corrosion-resistant materials to combat the effects of saltwater. Consulting with an experienced civil engineer or urban planner is advisable to ensure that the chosen solution is both effective and sustainable. In practical terms, installing a gully grid drain cover involves intricate coordination. The installation team must assess the subsurface conditions, verifying that there are no underlying obstructions or vulnerabilities that might undermine the drain cover during extreme weather conditions. A precise fit is essential, as any misalignment could result in compromised drainage efficiency or increased maintenance demands. Authoritativeness in the industry is often demonstrated by market leaders who produce gully grid drain covers. Companies with decades of experience typically offer superior design and innovation, as well as a depth of knowledge in meeting diverse urban infrastructure challenges. Their extensive research and development efforts are pivotal in advancing this niche of urban development, introducing new materials and technologies that enhance both performance and environmental sustainability. Moreover, maintaining public safety and infrastructure integrity underlines the importance of installing reliable drain covers. An unfit or poorly installed drain cover could pose hazards such as trip and fall accidents, infrastructure damage, or flood risks. Regular maintenance checks, timely replacements, and adherence to safety guidelines play a vital role in upholding the longevity and functionality of these vital urban assets. In conclusion, the gully grid drain cover is far more than a mere utility component; it is an embodiment of engineering prowess, urban planning expertise, and manufacturing excellence. While the public may take these underground guardians for granted, the professionals behind their production and installation understand their substantial impact on enhancing urban living conditions. Trust in their dependability and commitment to quality ensures that cities function smoothly, no matter the weather or urban demand.

Latest news

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025