Grooved Butterfly Valve Featuring Integrated Tamper Switch for Enhanced Control and Safety

Grooved Butterfly Valve with Tamper Switch A Comprehensive Overview

In industrial applications and modern plumbing, the integration of advanced components enhances both safety and efficiency. One such innovation is the grooved butterfly valve equipped with a tamper switch. Understanding the functionalities and benefits of this valve type can provide insights into its increasing popularity in various sectors.

What is a Grooved Butterfly Valve?

A grooved butterfly valve is designed to regulate and control the flow of fluids within a system. Its structure comprises a circular disc or blade that rotates 90 degrees to open or close the valve. The grooved aspect refers to the valve's connection method—the valve body is designed with grooves that enable a secure and leak-proof connection to pipes. This method streamlines installation, reduces the need for complex fittings, and minimizes potential leak points, making it an efficient choice for many industrial applications.

Functionality of the Tamper Switch

Incorporating a tamper switch within the butterfly valve adds a layer of safety and security that is essential in many industries. A tamper switch is a sensitive device that detects unauthorized access or interference with the valve mechanism. This switch provides an alert, ensuring that any attempts to manipulate or disable the valve are immediately communicated to the control system or the supervising personnel.

The inclusion of a tamper switch is particularly beneficial in critical applications where maintaining fluid integrity and system pressure is crucial, such as in chemical processing, water treatment, and fire protection systems. By using this technology, organizations can better protect their infrastructure and prevent costly spills or accidents.

Benefits of Using Grooved Butterfly Valves with Tamper Switches

grooved butterfly valve with tamper switch

1. Enhanced Safety The primary advantage of the tamper switch is the improved safety it offers. By monitoring the valve's status and detecting unauthorized access, it helps prevent potential system failures or hazardous situations.

2. Efficient Installation The grooved connection method simplifies installation and reduces labor costs. Installers can quickly connect the valve to existing piping systems without complicated joining techniques, resulting in reduced downtime.

3. Compact Design Butterfly valves are generally more compact compared to other valve types, allowing for space-saving installations. This feature is particularly valuable in environments where space is limited, such as in densely packed industrial settings.

4. Versatility Grooved butterfly valves are versatile and can be used in various applications—from water and wastewater management to HVAC systems. Their ability to handle different types of fluids, including clean water, slurries, and even gases, underscores their adaptability.

5. Cost-Effectiveness The combination of easy installation, low maintenance requirements, and reliable performance makes grooved butterfly valves with tamper switches a cost-effective choice for many businesses. Over time, these valves can lead to significant savings in maintenance and replacement costs.

Conclusion

As industries continue to evolve, the need for reliable and safe fluid control mechanisms becomes increasingly paramount. The grooved butterfly valve with a tamper switch exemplifies an innovative solution, combining efficient design with enhanced security features. By understanding the benefits and functionalities of these valves, organizations can make informed decisions about their fluid control systems, ultimately leading to improved operational efficiency and safety. Whether in manufacturing, water management, or fire protection, these technologically advanced valves are shaping the future of industrial fluid control.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

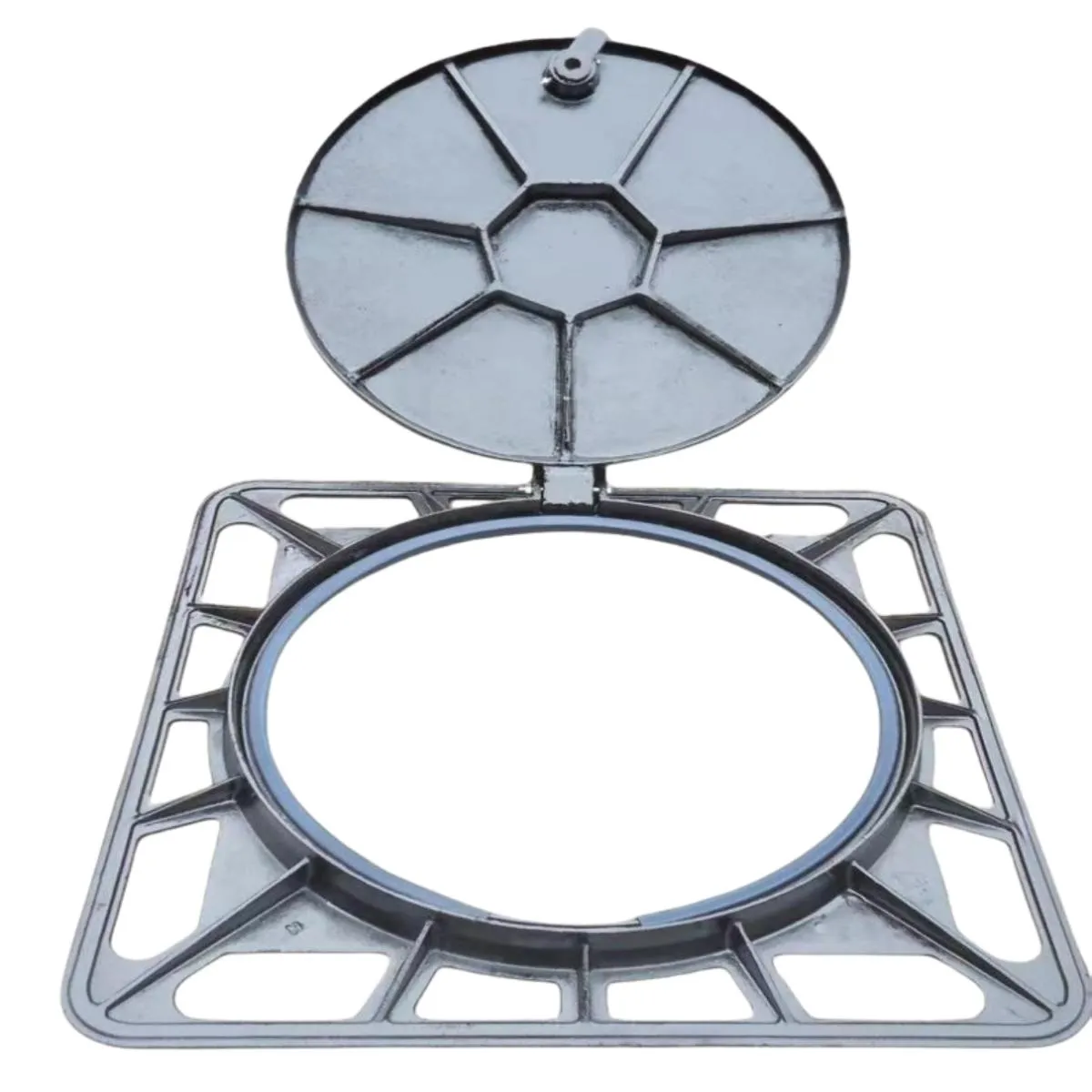

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025