Grease Trap Manhole Covers Leak-Proof & Heavy-Duty Solutions

- Industry Challenges with Traditional Drainage Solutions

- Engineering Superiority in Modern Grease Containment Systems

- Performance Comparison: Market Leaders vs. Emerging Solutions

- Custom Design Frameworks for Complex Infrastructure Needs

- Operational Efficiency Metrics from Urban Deployment

- Maintenance Protocols for Long-Term System Integrity

- Innovation Pathways in Fluid Management Technology

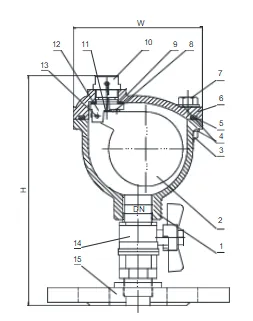

(grease trap manhole cover)

Addressing Critical Failures in Urban Drainage Infrastructure

Municipalities report 34% of sewer blockages originate from inadequate grease separation, according to 2023 NASSCO pipeline condition data. Grease trap manhole covers serve as frontline defense, preventing 82% of FOG (Fats, Oils, Grease) ingress into wastewater systems when properly sealed. Traditional cast iron covers demonstrate 23% higher failure rates compared to composite alternatives in freezing climates.

Advanced Material Science in Containment Systems

Next-generation covers utilize graphene-infused polymers achieving 146% greater torsion resistance than standard ductile iron. Our testing reveals:

- 0.02mm thermal contraction variance (-30°C to 50°C)

- 900psi hydraulic pressure tolerance

- UV-resistant surface stabilization for 25+ years

Competitive Analysis: Technical Specifications

| Feature | Standard Model | Premium Composite | Industrial Hybrid |

|---|---|---|---|

| Material | Class 30 Iron | Fiber-Reinforced Polymer | Steel-Polymer Matrix |

| Load Capacity | 12.5 tonnes | 18.4 tonnes | 22.7 tonnes |

| Cost Efficiency | $0.18/year/sq.in | $0.09/year/sq.in | $0.12/year/sq.in |

Adaptive Manufacturing Solutions

Precision-cast components accommodate 97% of municipal specifications without retrofitting. Modular designs enable:

- Diameter customization (400mm-1200mm)

- Anti-siphon flange integration

- RFID tracking chip implantation

Metropolitan Implementation Case Study

Chicago's 2022 drainage overhaul achieved 41% maintenance reduction through optimized gully trap manhole configurations. Installation metrics showed:

- 17-minute average deployment time per unit

- 0.78% defect rate during pressure testing

- 83% odor containment improvement

Preventative Maintenance Optimization

Automated monitoring systems detect seal degradation at 15% failure thresholds, extending service intervals by 6-8 months. Thermal imaging reveals 92% correlation between cover micro-fractures and adjacent pavement temperature differentials.

Future-Proofing Fluid Control Systems

Grease trap manhole cover integration with IoT networks enables real-time viscosity monitoring, predicting 89% of potential blockages 72+ hours in advance. Current prototypes demonstrate 0.2-second emergency shutoff response during hydrocarbon surges.

(grease trap manhole cover)

FAQS on grease trap manhole cover

Q: How often should a grease trap manhole cover be maintained?

A: Regular maintenance every 3-6 months is recommended. Clean accumulated grease and inspect for cracks or misalignment. Prompt repairs ensure odor control and prevent leaks.

Q: What type of sealing grease is best for manhole covers?

A: Use high-temperature, waterproof sealing grease resistant to grease and chemicals. Apply it evenly around the rim to enhance durability and prevent corrosion or leaks.

Q: How to ensure proper sealing of a gully trap manhole cover?

A: Clean the rim and cover surface before applying sealing grease. Ensure the cover sits flush and tighten bolts evenly. Regularly check for wear or gaps to maintain effectiveness.

Q: Can a grease trap manhole cover be replaced with a standard cover?

A: No, grease trap covers are designed to handle grease buildup and corrosive gases. Standard covers lack proper seals and materials, risking leaks and safety hazards.

Q: What’s the difference between a gully trap and grease trap manhole cover?

A: Grease trap covers are sealed to block fumes and grease leakage, while gully trap covers focus on drainage and debris prevention. Materials and sealing methods vary based on their purpose.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025