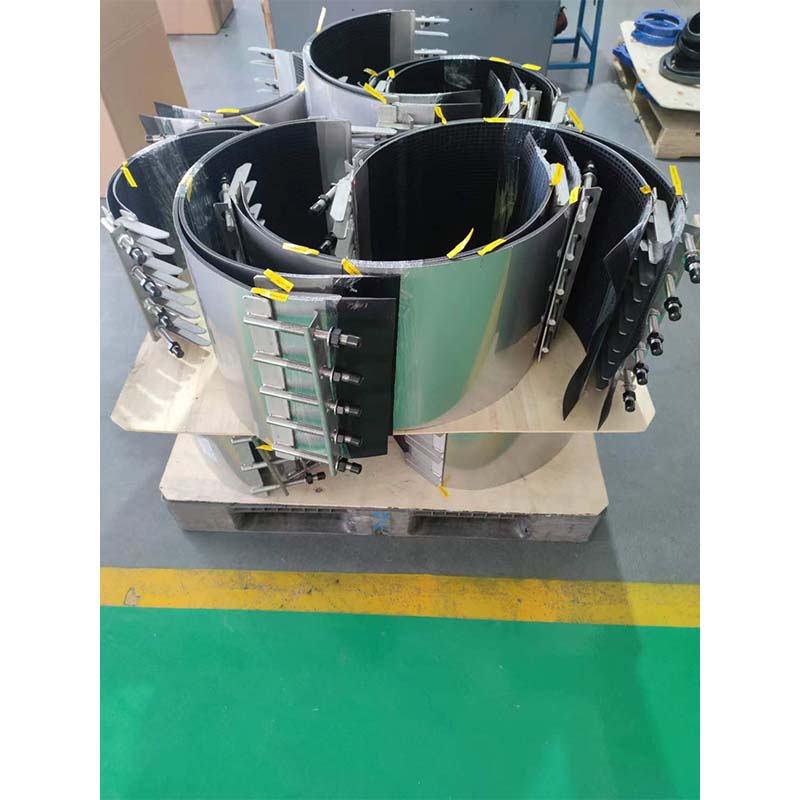

gate valve with nipple

Understanding the Gate Valve with Nipple A Comprehensive Overview

Gate valves are critical components in piping systems, widely used in various industrial applications for controlling fluid flow. Among the different configurations of gate valves, those featuring a nipple connection have gained popularity due to their versatility and reliable performance. This article delves into the specifics of gate valves with nipples, their functionality, advantages, and applications.

What is a Gate Valve?

A gate valve is a type of valve that opens and closes by raising or lowering a gate-like mechanism. Unlike other valves, such as globe valves or ball valves, gate valves provide minimal resistance to fluid flow when fully opened, making them ideal for on/off service rather than throttling. They are often used in applications where a straight-line flow of fluid and low pressure drop is essential.

Understanding the Nipple Connection

A nipple in plumbing and piping refers to a short piece of pipe, usually with male threads on both ends, used to connect two female pipe fittings. In the context of gate valves, a nipple provides a robust way to attach the valve to adjacent piping, ensuring a secure and leak-proof connection. The integration of a nipple into a gate valve design enhances its functionality and installation versatility, especially in tight spaces.

Design and Construction

Gate valves with nipples are typically constructed from durable materials such as stainless steel, carbon steel, or ductile iron, making them suitable for high-pressure and high-temperature applications. The choice of material depends on the specific requirements of the application, including the type of fluid being handled, temperature, and pressure conditions.

These valves may come with various types of nipples, including threaded and welded options. Threaded nipples allow for easy installation and disassembly, making maintenance more convenient. On the other hand, welded nipples can provide a more permanent and secure connection, reducing the risk of leaks.

Advantages of Gate Valves with Nipple Connections

1. Low Flow Resistance One of the primary advantages of gate valves is their ability to provide nearly unrestricted flow when fully open. This is crucial in processes that require high flow rates.

gate valve with nipple

3. Ease of Installation The nipple connection simplifies the installation process, reducing labor costs and time. Both threaded and welded nipple options can accommodate various installation needs.

4. Versatility These gate valves are versatile in that they can be used in a variety of applications, from water supply systems to oil and gas industries, thus appealing to a wide range of sectors.

5. Durability Built with robust materials, gate valves with nipples offer longevity and reliable performance under demanding conditions, minimizing the frequency of replacements and repairs.

Applications

Gate valves with nipple connections are used across numerous industries and applications, including

- Water Supply Systems Given their ability to handle high volumes of water with minimal resistance, these valves are standard in municipal water systems. - Oil and Gas In this sector, the ability to maintain pressure and ensure leak-proof connections is paramount, making gate valves with nipples ideal.

- Chemical Processing These valves can withstand corrosive fluids and high temperatures, making them suitable for various chemical handling applications.

- Power Generation In power plants, gate valves are used in cooling systems and feedwater lines, where efficiency and reliability are crucial.

Conclusion

In summary, gate valves with nipples represent a vital component in modern piping systems, providing essential features such as low flow resistance, ease of installation, and durability. Their widespread use across different industries underscores their importance in facilitating efficient fluid control. Whether in municipal water systems, oil and gas applications, or chemical processing, understanding the advantages and functionalities of gate valves with nipple connections can enhance operational efficiency and safety in various industrial environments.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025