Gate Valve Price—Want Bulk Discounts, Fast Shipping, OEM?

When people ask about gate valve price, they usually want a quick number. To be honest, it depends—on standards, pressure class, coatings, lead time, even exchange rates. And here’s the twist: the total cost of a pipeline is heavily influenced by companion valves too, like air release valves that quietly prevent surge and energy loss. I’ve seen projects save more by choosing the right air release valve than shaving a few dollars off a gate valve.

Market trends and what really moves pricing

Raw material volatility (ductile iron, stainless), fusion-bonded epoxy (FBE) costs, stricter testing (EN 12266-1), and project certification needs all nudge numbers up or down. Lead-time premiums are real. Digital documentation and third‑party inspection? Also a factor. Surprisingly, freight sometimes swings the final figure more than the hardware.

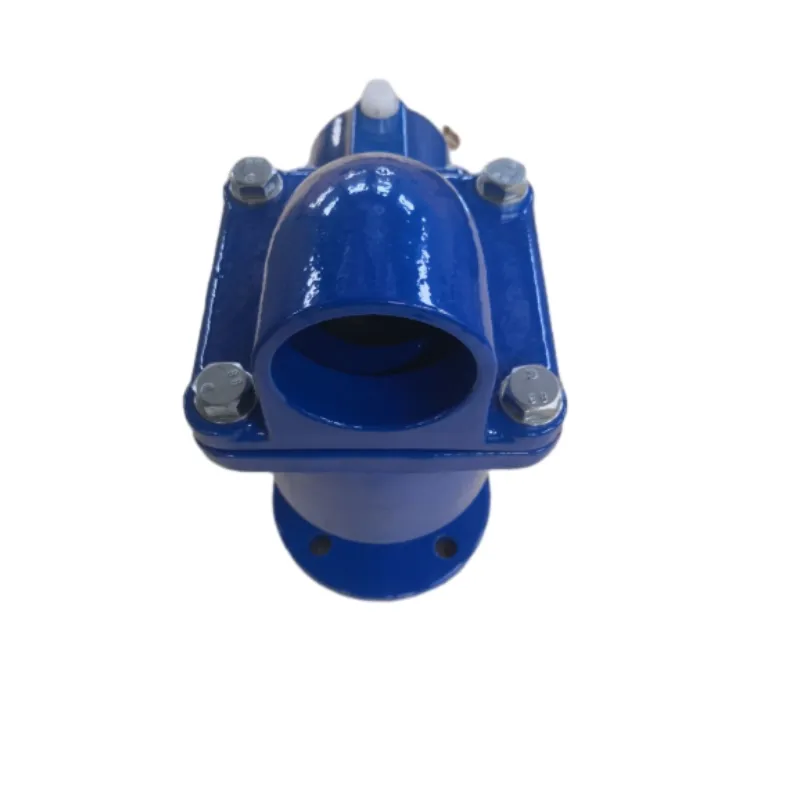

Spotlight: Double Orifice Air Release Valve (cost saver in disguise)

Origin: Room 1005, Building 1-2, Phase I, North China Golden Sun Commercial City, Xinhuanan Road, Xiangdu District, Xingtai City, Hebei Province, China. Designed to EU standards and coated inside-out with FBE, it’s built for municipal water lines and neutral oils. It’s not a gate valve, sure, but it often reduces pump energy and burst incidents—cutting lifecycle cost, which is why I bring it up in any gate valve price talk.

| Design | EN 1074-4:2000; Flange EN 1092-2:1997 |

| Testing | EN 12266-1:2012; Shell 25 kgf/cm²; Seat 18 kgf/cm² |

| Working Pressure | 16 kgf/cm² (≈ PN16) |

| Media | Water, neutral oil |

| Coating | 100% fusion‑bonded epoxy (internal/external) |

| Fasteners | SS304/316 optional |

| Service Life | 10–20 years in treated water (real‑world may vary) |

Manufacturing and QA flow (short version)

Materials (DI body, brass/SS internals) → precision machining → orifice pairing → FBE coating → assembly with SS304/316 fasteners (on request) → hydrostatic shell and seat tests per EN 12266‑1 → documentation pack → crating. Every stage has traceability; I’ve seen test reports stamped with actual pressures, which buyers appreciate.

Use cases and outcomes

Municipal trunk mains, irrigation risers, industrial cooling loops, even neutral oil transfer. One coastal utility added double‑orifice vents every 800 m on a PN16 ductile‑iron line; line breaks dropped 40% and pumping kWh fell ≈3%—small on paper, big on the bill. Many customers say the payback sneaks up within a year.

| Vendor | Origin | Standards | Customization | Lead Time | Price Level |

|---|---|---|---|---|---|

| HBYQ Metal (Double Orifice) | Hebei, China | EN 1074‑4, EN 1092‑2, EN 12266‑1 | FBE, SS304/316, flange options | 3–6 weeks (≈) | Lower‑mid |

| EU Brand A (Gate/Air) | EU | EN/AWWA mixes | High (docs heavy) | 6–10 weeks | High |

| India Maker B (Gate) | India | EN 1074/ISO variants | Moderate | 4–8 weeks | Mid |

Customization pointers

- SS304/316 bolts/nuts/washers for coastal or chlorinated water.

- FBE thickness matched to ISO 12944 corrosivity class.

- Orifice sizing tuned for transient control; add isolation cocks.

Quick pricing guidance (FOB, indicative)

- DN100 PN16 ductile iron gate valve: mid two‑digit to low three‑digit USD; real‑world varies with docs and coatings.

- DN50–DN100 double‑orifice air release valve: often lower than gate valves and pays back via energy and burst reduction.

- Drivers of gate valve price: diameter, PN rating, FBE quality, SS hardware, certification set, MOQ, Incoterms.

Customer feedback? It seems that utilities favor valves that arrive with clean EN 12266‑1 test sheets and consistent FBE finish. Fewer installation surprises, fewer call‑outs later.

Authoritative citations

- EN 1074‑4:2000 – Valves for water supply systems: Air valves.

- EN 1092‑2:1997 – Flanges and their joints: Cast iron flanges.

- EN 12266‑1:2012 – Industrial valves: Testing of metallic valves.

- ISO 12944 – Paints and varnishes: Corrosion protection of steel structures.

-

Durable & Safe 600mm Round Drain Covers | HBYQ Metal SolutionsNewsNov.25,2025

-

Comprehensive Guide to Square to Round Recessed Drain Cover 500mm | Durable & Efficient Drainage SolutionsNewsNov.24,2025

-

Round to Square Manhole Cover – Adaptive Infrastructure Solutions for Modern CitiesNewsNov.24,2025

-

Square to Round Recessed Drain Cover 450mm – Durable & Efficient Drainage SolutionsNewsNov.23,2025

-

Durable Round Inspection Chamber Covers for Urban and Industrial Use | HBYQ MetalNewsNov.23,2025

-

Square to Round Recessed Drain Cover | Durable & Adaptable Drain SolutionsNewsNov.22,2025

-

Durable Square to Round Recessed Drain Cover 300mm | Reliable Drain SolutionsNewsNov.22,2025