Galvanised Step Irons: Anti-Slip, Corrosion-Resistant?

What’s Changing With galvanised step irons in 2025

If you work around drainage or sewer assets, you know the humble step iron is anything but trivial. And lately, the market’s been shifting—more composite encapsulation, tighter testing, quicker lead times. I’ve been visiting yards and site crews, and—honestly—there’s a clear preference for hi‑vis encapsulated steel. It’s tough, visible, and predictable underfoot.

Industry trend snapshot

Utilities are standardizing on galvanised step irons with polypropylene encapsulation to cut corrosion and improve visibility in low-light chambers. Interestingly, specifiers are pushing for documented salt-spray and slip tests, not just “galvanized—tick.” And real talk: crews like rungs that don’t chew up boots and feel grippy when it’s wet.

What they’re made of (and why it matters)

- Core material: low-carbon steel (Q235/ASTM A36 range) for ductility under impact.

- Coating: hot-dip galvanizing per ISO 1461 / ASTM A123—zinc layer ≈70–85 µm in typical production; real-world may vary by job.

- Encapsulation: hi‑vis polypropylene overmould—UV-stabilized, chamfered edges, aggressive tread texture.

- Finish: serrated/knurled top for wet grip; closed ends to resist debris buildup.

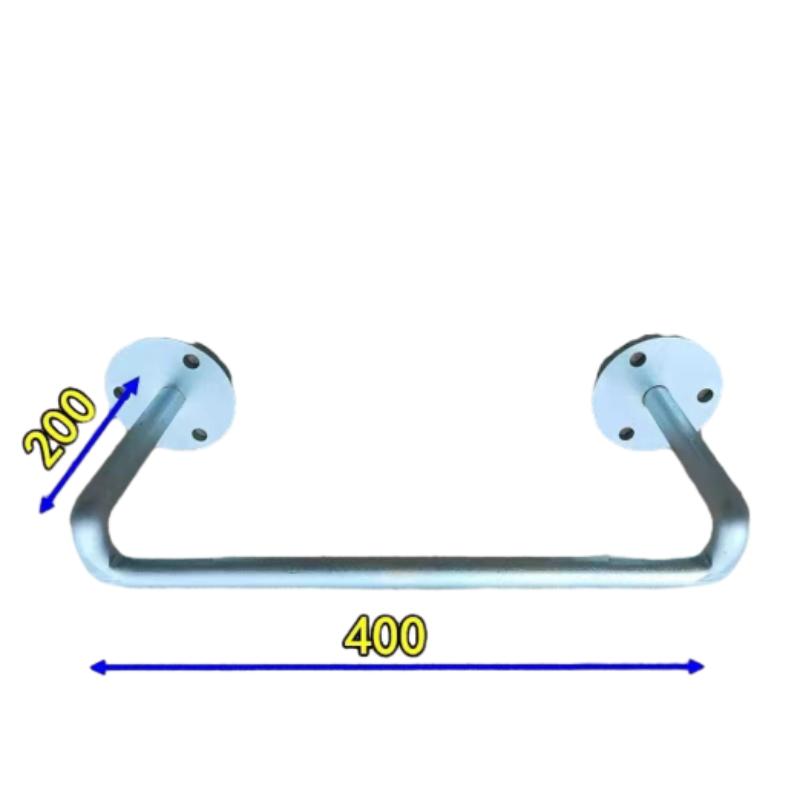

Core specs (typical)

| Item | Specification (≈ values; project specs prevail) |

| Bar diameter | 12–16 mm steel core, encapsulated to ~25–30 mm tread thickness |

| Clear tread width | 260–300 mm common; center spacing to client drawing |

| Load rating | ≥2.5 kN vertical, ≥1.5 kN transverse (per BS EN 13101 test methods) |

| Zinc coating | Hot-dip, target 70–85 µm; ISO 1461 / ASTM A123 compliant |

| Service life | ≈25–50 years depending on soil chemistry and effluent exposure |

| Install options | Cast-in sockets or chemical anchors (M12 typical) |

| Compliance | BS EN 13101; galvanizing to ISO 1461/ASTM A123; corrosion testing to ISO 9227 |

How they’re built (process flow)

- Cut and bend steel bar to jigged geometry; weld end tabs where specified.

- Hot-dip galvanize; verify zinc thickness using magnetic gauge (per ISO 1461).

- Injection overmould polypropylene; inspect adhesion and encapsulation coverage.

- Proof-load testing per BS EN 13101; visual and slip-tread verification.

- Optional salt-spray exposure (ISO 9227) for QA sampling; document results.

- Packed in pairs or bundles with lot traceability—useful when councils audit.

Where they’re used

Municipal stormwater pits, sewer manholes, wastewater plants, utility vaults, irrigation channels, and inspection chambers in industrial estates. Crews often tell me galvanised step irons with hi‑vis skins cut search time underground—small but real safety win.

Vendor landscape (quick comparison)

| Vendor | Coating standard | MOQ | Lead time | Customization | Certs | Warranty |

| HB YQ Metal (Hebei, China; Room 1005, Building 1-2, Xinhuanan Rd, Xingtai) | ISO 1461 / ASTM A123 | ≈200 pcs | 2–4 weeks | Sizes, colors, logo, sockets | EN 13101 test report | 12–24 months |

| Regional Foundry A | ISO 1461 | ≈100 pcs | 1–3 weeks | Limited colors | In-house QA | 12 months |

| Importer B | ASTM A123 (declared) | ≈500 pcs | 4–6 weeks | By batch | Supplier CoC | 6–12 months |

Real-world notes and mini case studies

A NSW council swapped legacy painted rungs for galvanised step irons with orange skins across 180 pits; crews reported faster visual checks and fewer rust streaks after 12 months. In a coastal treatment plant upgrade, the contractor requested extra zinc (≈100 µm target) after ISO 9227 salt-spray benchmarking—slightly pricier, but maintenance said it was “cheap insurance.”

Customization tips

Ask for shop drawings with hole centers and embed depth, confirm color (hi‑vis orange or yellow), and specify the galvanizing standard on PO lines. If you expect aggressive H2S, consider thicker zinc and more frequent QA sampling.

Installer feedback: “Pre-drilled templates saved hours; encapsulation didn’t crack under hammer taps,” one foreman told me. Not scientific, but it tracks with what I’ve seen.

Certifications, testing, and service life

- Design and proof-load per BS EN 13101 (steps for underground manholes).

- Galvanizing verified to ISO 1461 or ASTM A123, with thickness reports.

- Optional corrosion qualification via ISO 9227 salt spray (QA sampling).

- Typical life: ≈25–50 years; soil pH, chlorides, and abrasion are the big variables.

References

- BS EN 13101: Steps for underground manholes — Design, requirements and testing.

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

- ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings.

- ISO 9227: Corrosion tests in artificial atmospheres — Salt spray tests.

-

Square to Round Recessed Drain Cover 600mm – Durable and Efficient Drainage SolutionsNewsNov.20,2025

-

Durable Sewer Covers Round for Safe and Efficient Urban Infrastructure | HBYQ MetalNewsNov.19,2025

-

Durable 500mm Round Inspection Chamber Covers for Global Infrastructure NeedsNewsNov.19,2025

-

Comprehensive Guide to Storm Drain Cover Round: Design, Trends & Global InsightsNewsNov.18,2025

-

Durable and Innovative Round Drain Cover Solutions for Modern InfrastructureNewsNov.18,2025

-

Durable Round Manhole Cover Solutions for Modern InfrastructureNewsNov.18,2025

-

Manhole Cover Circle: Essential Guide to Durable, Safe & Smart Urban SolutionsNewsNov.17,2025