Innovative Full Circle Repair Clamp for Efficient Pipe Maintenance and Leak Prevention

Understanding Full Circle Repair Clamps A Comprehensive Overview

In the world of piping and plumbing, the integrity of systems is crucial for ensuring seamless operations. Whether found in residential plumbing, industrial applications, or municipal water systems, the need for reliable and effective repair solutions has led to the innovation of full circle repair clamps. These tools are essential for addressing a variety of challenges faced by piping systems.

A full circle repair clamp is designed specifically to provide a robust solution for repairing damaged pipes without the need for extensive disassembly or replacement. Unlike traditional methods that often require cutting out sections of the pipe, these clamps allow for a quick and efficient way to restore function to a compromised system.

Design and Functionality

The design of a full circle repair clamp typically consists of a solid metal band that encircles the entire circumference of the pipe. The clamp is equipped with bolts or screws that secure it in place, compressing the damaged section to create a watertight seal. This design not only reinforces the structure of the pipe but also prevents leaks, which can be detrimental to both the environment and the operational efficiency of any system.

One of the key features of a full circle repair clamp is its versatility. It can be utilized on various pipe materials, including cast iron, PVC, and steel, making it a popular choice across multiple industries. Additionally, these clamps come in various sizes to accommodate different pipe diameters, ensuring a perfect fit for virtually any repair scenario.

Benefits of Full Circle Repair Clamps

1. Speed and Convenience Full circle repair clamps are designed for quick installation, allowing repairs to be made in a fraction of the time it would take with more traditional methods. This rapid response is critical in minimizing downtime, particularly in industrial settings where production can be adversely affected by leaks or breaks.

full circle repair clamp

2. Cost-Effectiveness Utilization of full circle repair clamps can lead to significant cost savings. By avoiding the need for extensive pipe replacement or the labor-intensive process of cutting and welding, businesses can allocate resources more efficiently. Additionally, the long-lasting nature of these clamps means that they provide a reliable solution with minimal ongoing maintenance costs.

3. Reduced Disruption Traditional repair methods often require significant disruption to the surrounding environment, which can lead to additional costs and complications. Full circle repair clamps, however, require minimal excavation or demolition, allowing for repairs to be made with minimal interruption to the surrounding infrastructure.

4. Environmentally Friendly By repairing rather than replacing, full circle repair clamps contribute to a more sustainable approach in managing piping systems. This practice reduces waste and conserves materials, aligning with modern sustainability initiatives.

Applications of Full Circle Repair Clamps

Full circle repair clamps are employed in a wide array of applications. In municipal water systems, they are used to quickly fix leaks or breaks in water mains, ensuring that communities have access to uninterrupted water supply. In industrial settings, these clamps can be utilized in manufacturing processes where pipes frequently experience wear and tear. Additionally, they are commonly used in residential plumbing for swift repairs, thereby avoiding costly water damage.

Conclusion

In conclusion, full circle repair clamps represent a significant advancement in the maintenance and repair of piping systems. Their ability to provide quick, efficient, and cost-effective repairs helps ensure the longevity and reliability of plumbing infrastructures. As industries continue to seek solutions that enhance operational efficiency while minimizing costs and environmental impact, the full circle repair clamp will undoubtedly remain an invaluable tool in the realm of pipe repair. With ongoing innovations and improvements in design, these clamps are poised to play a critical role in the future of plumbing and piping maintenance.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

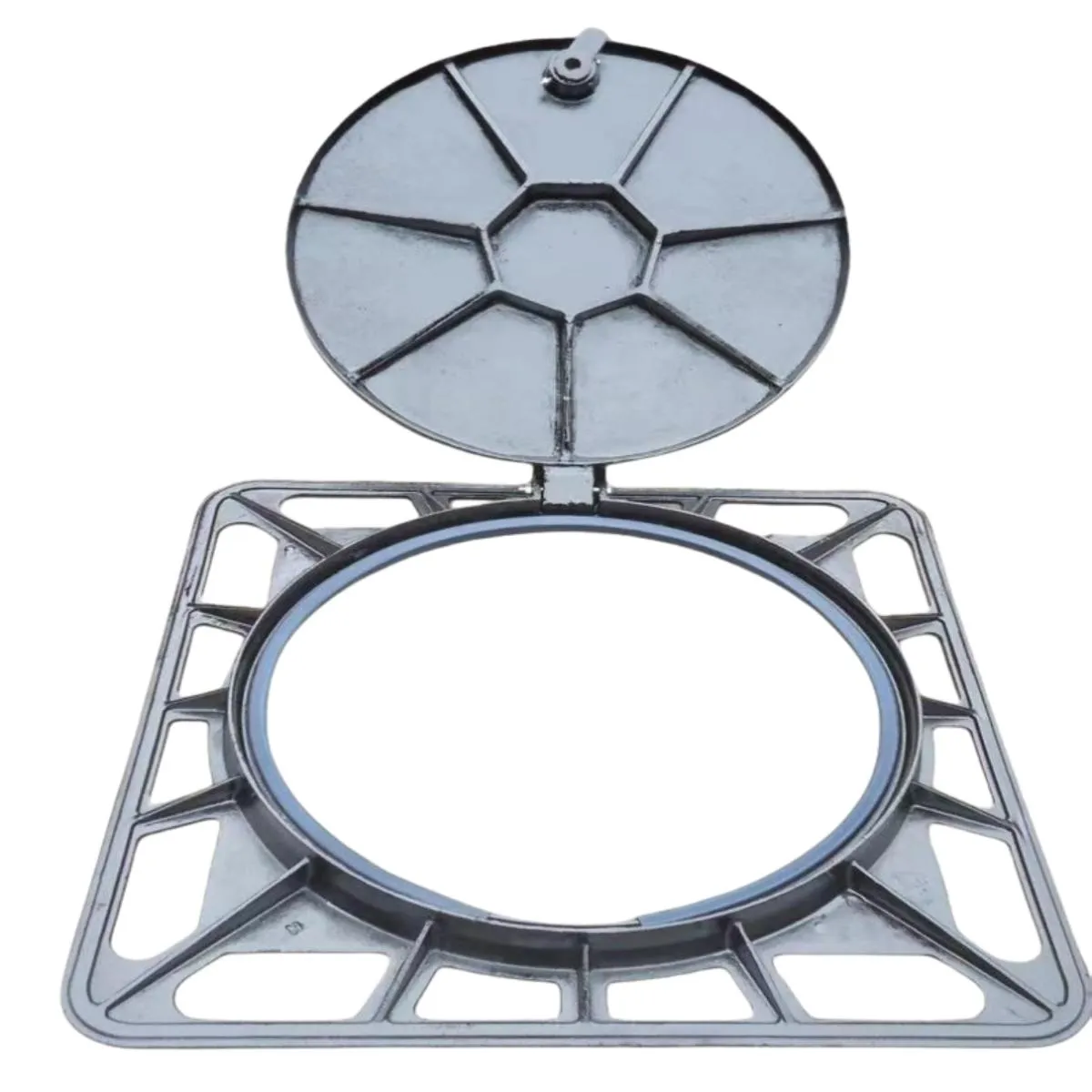

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025