Electric Actuated Butterfly Valve for Precise Flow Control in Industrial Applications

Electric Control Butterfly Valve An Overview

The electric control butterfly valve is a critical component in many industrial applications, serving as a robust solution for regulating fluid flow with high efficiency and precision. This valve type is particularly favored in sectors where system automation and energy savings are paramount. This article explores the design, functionality, benefits, and applications of electric control butterfly valves, highlighting their significance in modern industrial systems.

Design and Functionality

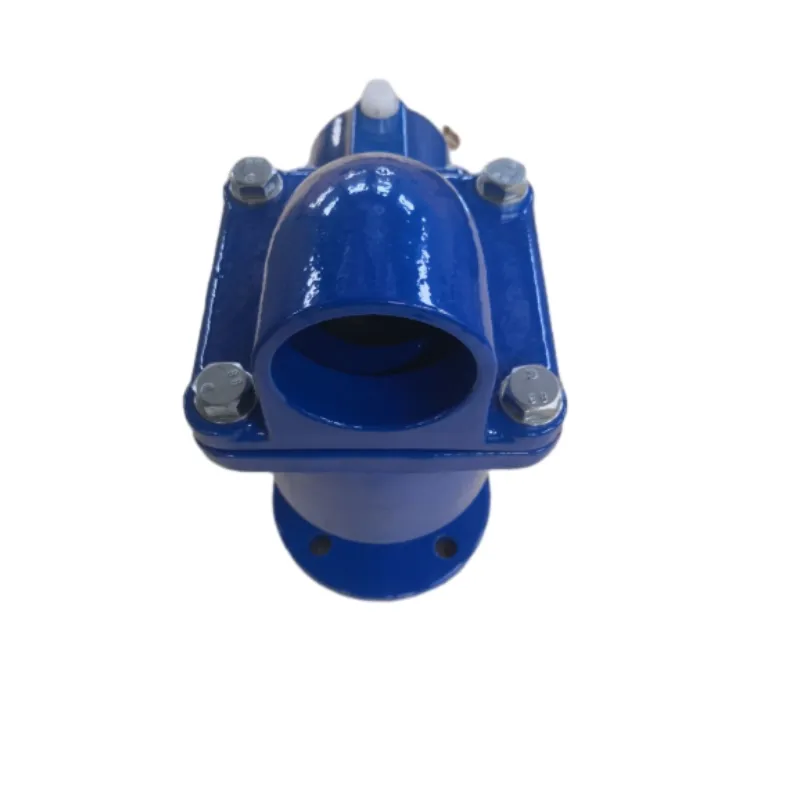

The electric control butterfly valve consists of a disc that rotates around a central axis to regulate flow. The valve is named after its disk's resemblance to a butterfly's wings when open. At the heart of its operation is an electric actuator, which transforms electrical energy into mechanical motion, allowing for precise control of the valve opening and closing.

One of the primary features of electric control butterfly valves is their ability to handle large volumes of fluid with minimal pressure drop. This efficiency results from their compact design and the streamlined flow path that minimizes turbulence. Furthermore, these valves can be constructed from various materials, including stainless steel, cast iron, and plastic, to suit different operational environments and media types, such as water, oil, and gas.

Advantages

The advantages of electric control butterfly valves are numerous, making them a preferred choice for many applications

1. Energy Efficiency Electric actuators can be integrated with control systems, allowing for automation that optimizes energy consumption. This helps reduce operational costs while enhancing overall system efficiency.

2. Precision Control Electric control valves provide accurate flow regulation, which is crucial in processes requiring specific operational parameters. This precision helps in maintaining product quality and process stability.

3. Quick Response Time The electric actuator ensures rapid valve operation, facilitating quick adjustments to changing system conditions. This responsiveness is vital in dynamic environments where immediate control over fluid flow is necessary.

4. Reduced Maintenance Unlike pneumatic or hydraulic systems, electric control butterfly valves require less maintenance. They are typically equipped with fewer moving parts, which reduces wear and tear and increases reliability in continuous operation.

electric control butterfly valve

5. Environmental Benefits The ability to control flow rates helps minimize waste and emissions, contributing to a greener operational footprint. The precise regulation of fluids also reduces the risk of spills or leaks.

Applications

Electric control butterfly valves find extensive applications across various industries

- Water and Wastewater Treatment These valves are crucial in managing water distribution systems and treatment processes, ensuring optimal flow rates and maintaining environmental standards.

- Power Generation In power plants, electric control butterfly valves manage steam and cooling water systems, playing a vital role in maintaining operational efficiency.

- Chemical Processing The ability to control corrosive or viscous fluids makes these valves a preferred choice in chemical manufacturing, where precise flow control is essential for reaction processes.

- Food and Beverage Industry Maintaining hygiene and preventing contamination are critical in this industry. Electric control butterfly valves are used to regulate flow in processing and packaging applications while adhering to strict sanitary standards.

- HVAC Systems These valves are employed in heating, ventilation, and air conditioning systems to control flow rates and temperatures, contributing to energy-efficient climate control solutions.

Conclusion

The electric control butterfly valve represents a significant advancement in fluid control technology, offering unparalleled efficiency and precision for various industrial applications. Its design, coupled with the robust functionality of electric actuators, makes it a reliable choice for industries seeking automation and improved operational efficiency. As industries continue to evolve and demand greater control over processes, the electric control butterfly valve will undoubtedly play a crucial role in shaping the future of fluid management systems. Embracing this technology not only leads to improved performance but also supports sustainability initiatives through responsible resource management.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025