ductile iron covers and frames price

The Rising Trend in Ductile Iron Covers and Frames Prices

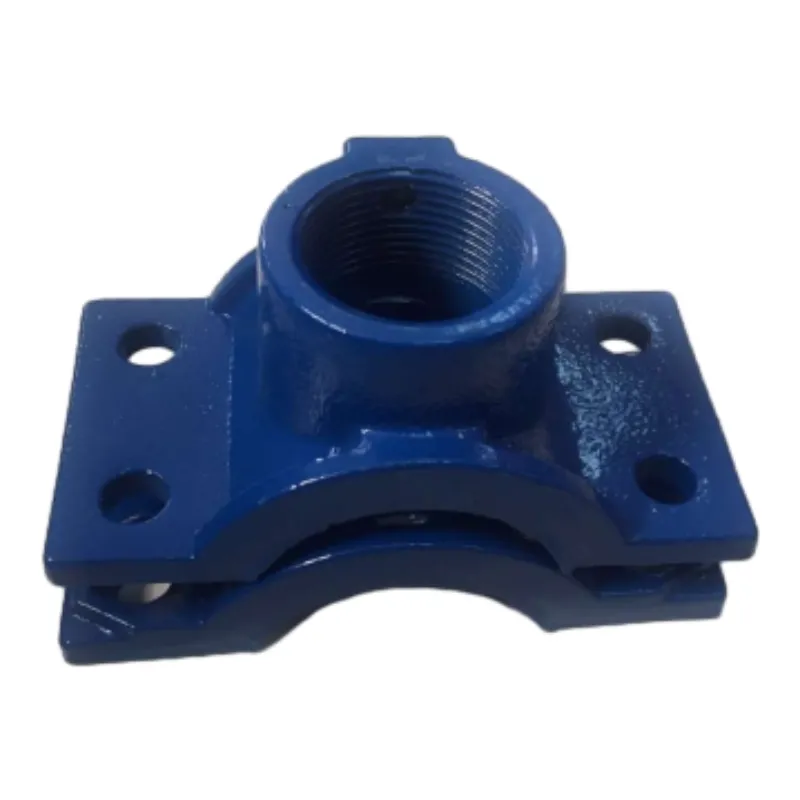

In recent years, the construction and infrastructure sectors have seen a notable shift in the materials chosen for various projects. Among these materials, ductile iron has emerged as a preferred option for manufacturing covers and frames used in roadways, manholes, and other utilities. The increasing demand for durable, resilient, and cost-effective solutions has consequently influenced the price dynamics of ductile iron covers and frames.

Ductile iron is an alloy with enhanced mechanical properties, making it ideal for components that require high strength and durability. Its superior resistance to corrosion, impact, and fatigue distinguishes it from traditional cast iron, thus justifying its growing popularity in a variety of applications. The lifecycle of ductile iron products often exceeds several decades, which is particularly appealing for municipalities and contractors looking to minimize long-term costs associated with repairs and replacements.

The Rising Trend in Ductile Iron Covers and Frames Prices

Additionally, the demand-supply dynamics within regional markets can greatly affect pricing. As urbanization and infrastructure development accelerate in many parts of the world, the demand for ductile iron covers and frames has surged. Cities are investing in new road systems, utilities, and drainage systems, all of which require high-quality materials. As demand continues to outpace supply in certain regions, manufacturers may find themselves compelled to adjust prices upward.

ductile iron covers and frames price

The manufacturing costs associated with ductile iron products also contribute to their pricing. Advances in production technology have created opportunities for increased efficiency and reduced waste, potentially leading to lower prices. However, manufacturers must also contend with rising energy costs, labor expenses, and regulatory compliance, all of which can further influence the final cost passed on to consumers.

Market trends also have an impact on ductile iron cover and frame prices. The construction industry is increasingly embracing sustainable practices and materials. As more growth-focused municipalities aim for environmentally-friendly solutions, ductile iron manufacturers are adapting by investing in greener production processes. While this shift may initially raise production costs, it may lead to long-term savings, influencing overall market prices for ductile iron products.

Additionally, competition among manufacturers can lead to fluctuations in pricing. As more companies enter the market, they may engage in competitive pricing strategies to gain market share. This could lead to lower prices in certain segments, especially if companies are willing to absorb some costs for a period. However, as manufacturers begin to establish their brand and reputation based on quality, prices may stabilize or increase as they emphasize the value of premium products.

The increased implementation of government regulations and standards in construction and safety can also affect prices. As municipalities enforce stricter guidelines for road safety and infrastructure integrity, manufacturers may need to enhance their products' quality, potentially resulting in higher production costs that are then reflected in pricing.

In conclusion, the pricing of ductile iron covers and frames is influenced by a complex interplay of raw material costs, demand-supply dynamics, manufacturing expenses, market trends, and competitive pressures. For consumers, understanding these factors can provide insights into the fluctuating market landscape and assist in making informed purchasing decisions. As the construction industry continues to evolve, the significance of cost-effective, durable materials like ductile iron will remain paramount, ensuring its place as a key player in infrastructure development globally.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025