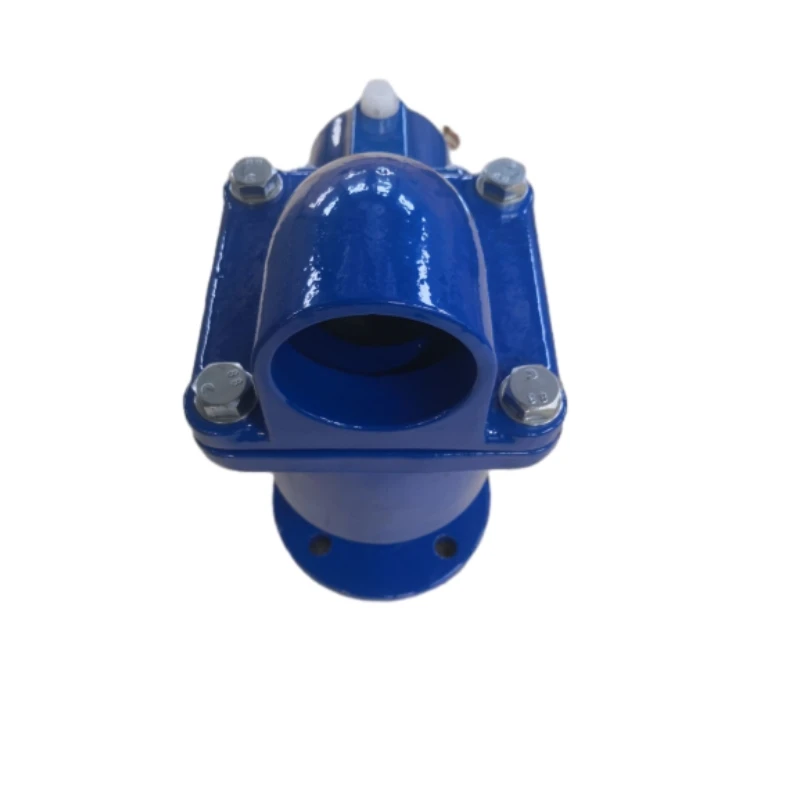

check valve butterfly

Check Valve Butterfly A Key Component in Fluid Control

In the world of fluid dynamics and control systems, the check valve butterfly emerges as a pivotal component, playing a crucial role in the management of fluid flow. Used primarily in piping systems, these valves are designed to prevent backflow while allowing forward flow, ensuring efficiency and safety in various applications.

A check valve butterfly combines the functionalities of a traditional check valve and a butterfly valve. While a standard check valve is typically used to prevent backflow in pipelines, the butterfly aspect of this design introduces unique advantages. The butterfly valve mechanism utilizes a rotating disc to regulate flow, which allows for quick and efficient control. This feature is particularly beneficial in systems where space is constrained, as butterfly valves typically require less physical space than other valve types.

One of the primary benefits of a check valve butterfly is its ability to handle large volumes of fluid with minimal pressure drop

. This characteristic is essential in many industrial applications, such as water supply systems, chemical processing, and HVAC systems. A low-pressure drop is crucial because it reduces energy consumption and enhances the overall efficiency of the system.check valve butterfly

Moreover, the design of the check valve butterfly allows for rapid response times. In dynamic environments where fluid flow can change suddenly, this swift response helps maintain the integrity of the system and prevents potential damage caused by backflow. Consequently, industries that rely on precise fluid control, such as oil and gas, pharmaceuticals, and food and beverage production, increasingly adopt these valves in their operations.

Material choice is another important aspect of check valve butterfly design. Manufacturers typically offer these valves in various materials, including stainless steel, ductile iron, and plastic, to cater to different environmental conditions and fluid types. For instance, stainless steel valves are ideal for corrosive liquids, while plastic options may be more suitable for non-corrosive applications.

Installation and maintenance of check valve butterfly systems are relatively straightforward, which further adds to their appeal. With proper installation, these valves can function effectively for years with minimal wear and tear. Regular inspections, cleaning, and prompt repairs when necessary can extend the lifespan of these valves, ensuring that they continue to perform optimally.

In conclusion, the check valve butterfly represents an innovative solution in fluid handling. Its combination of backflow prevention and efficient flow control makes it a strategic choice for numerous industries. As technology continues to evolve, these valves will likely see even broader applications, further solidifying their importance in fluid dynamics and control systems.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025