Feb . 10, 2025 10:41

Back to list

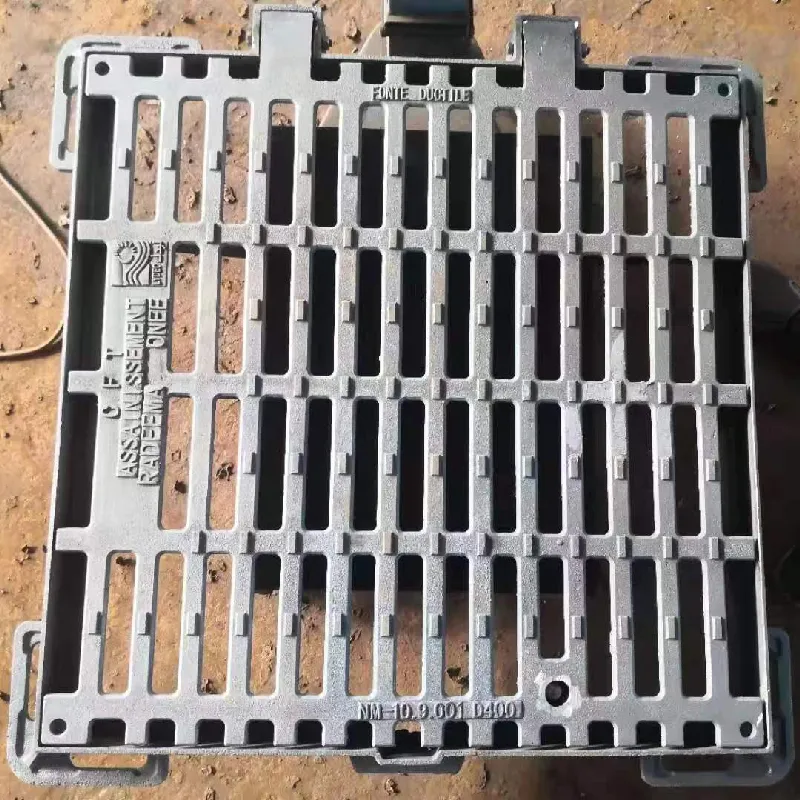

cast iron gully trap price

The landscape of acquiring high-quality plumbing systems often requires a noteworthy consideration of materials and cost, leading many to search for budget-friendly yet durable solutions. Among these, the cast iron gully trap shines as a reliable choice, not only for its effectiveness but also for its affordability. When diving into purchasing cast iron gully traps, it is crucial to have an in-depth understanding of the prices associated with these essential plumbing components, ensuring that investment aligns with both quality demands and budgetary constraints.

Location significantly impacts price, considering shipping costs and regional pricing strategies that are a result of logistical considerations. An analysis of local market conditions should thus be part of the purchasing strategy. In urban centers where supply chains are more efficient, prices might be more competitive compared to remote areas where access to such materials is limited. Another key consideration is the environmental aspect and sustainability credentials of the product. Manufacturers who engage in eco-friendly practices may offer products slightly more expensive owing to ethical production processes, yet appeal to businesses and consumers aiming to reduce their environmental footprint. Lastly, effective planning for installation costs alongside the primary material cost provides a comprehensive understanding of the financial requirements, ensuring no hidden fees disrupt the budget. Involving professional installation services promises optimal placement and reduces the risk of future issues, an investment into long-term savings. To conclude, while the initial price of cast iron gully traps can vary based on quality, brand reputation, and location, it is imperative for consumers to prioritize quality, compliance with industry standards, and sustainable practices. An informed purchase roots itself not merely in cost but in the assurance of superior performance, compliance with environmental standards, and the promise of longevity. By making such considered investments, consumers ensure that their systems are not only built to last but also contribute positively to the integrity of their infrastructure.

Location significantly impacts price, considering shipping costs and regional pricing strategies that are a result of logistical considerations. An analysis of local market conditions should thus be part of the purchasing strategy. In urban centers where supply chains are more efficient, prices might be more competitive compared to remote areas where access to such materials is limited. Another key consideration is the environmental aspect and sustainability credentials of the product. Manufacturers who engage in eco-friendly practices may offer products slightly more expensive owing to ethical production processes, yet appeal to businesses and consumers aiming to reduce their environmental footprint. Lastly, effective planning for installation costs alongside the primary material cost provides a comprehensive understanding of the financial requirements, ensuring no hidden fees disrupt the budget. Involving professional installation services promises optimal placement and reduces the risk of future issues, an investment into long-term savings. To conclude, while the initial price of cast iron gully traps can vary based on quality, brand reputation, and location, it is imperative for consumers to prioritize quality, compliance with industry standards, and sustainable practices. An informed purchase roots itself not merely in cost but in the assurance of superior performance, compliance with environmental standards, and the promise of longevity. By making such considered investments, consumers ensure that their systems are not only built to last but also contribute positively to the integrity of their infrastructure.

Latest news

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025