butterfly valve with pneumatic actuator and positioner

The Butterfly Valve with Pneumatic Actuator and Positioner An Overview

Butterfly valves are widely used in various industries due to their simple design, compact size, and efficiency in controlling the flow of fluids. When paired with a pneumatic actuator and a positioner, these valves offer enhanced performance and precision in flow control applications. This article explores the functionality and benefits of butterfly valves equipped with pneumatic actuators and positioners.

A butterfly valve consists of a disc that pivots around an axis to regulate flow. When the valve is fully open, the disc is aligned parallel to the flow, allowing maximum fluid passage. Conversely, when closed, the disc obstructs the flow. This simple mechanism makes butterfly valves ideal for on-off and throttling applications. Their lightweight construction allows for easy installation and maintenance, making them a popular choice across industries such as water treatment, pharmaceuticals, and chemical processing.

The integration of a pneumatic actuator further improves the operational efficiency of butterfly valves. Pneumatic actuators utilize compressed air to produce mechanical motion, allowing for rapid and precise valve operations. This feature is particularly beneficial in applications requiring quick response times. With a pneumatic actuator, the butterfly valve can be opened or closed in seconds, facilitating optimal flow control and reducing system response times.

butterfly valve with pneumatic actuator and positioner

In addition to providing actuation, incorporating a positioner into the system enables even finer control over the valve's position. A positioner is an instrument that ensures the valve reaches and maintains the desired position according to the control signal received from the automation system. This is crucial in scenarios where flow rates need to be adjusted dynamically based on process requirements. The positioner's feedback mechanism allows for continuous monitoring and adjustment, ensuring accuracy and stability in flow control.

One of the significant advantages of using a butterfly valve with a pneumatic actuator and positioner is the reduction of energy costs. The efficient design of butterfly valves means that less energy is required to operate them compared to other types of valves, such as gate or globe valves. Furthermore, the quick actuation capabilities of pneumatic systems minimize energy consumption during operation.

Safety is another important consideration. Pneumatic actuators can fail in a safe position, which is vital for critical processes. This inherent safety feature makes butterfly valves with pneumatic actuation an excellent choice for systems where reliable shut-off is essential.

In conclusion, butterfly valves equipped with pneumatic actuators and positioners offer a practical solution for effective flow control in various industrial applications. Their efficiency, quick actuation, and precision control not only enhance operational capabilities but also lead to cost savings and improved safety. As industries continue to evolve, the demand for such advanced valve systems is expected to rise, underscoring their significance in modern industrial automation.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

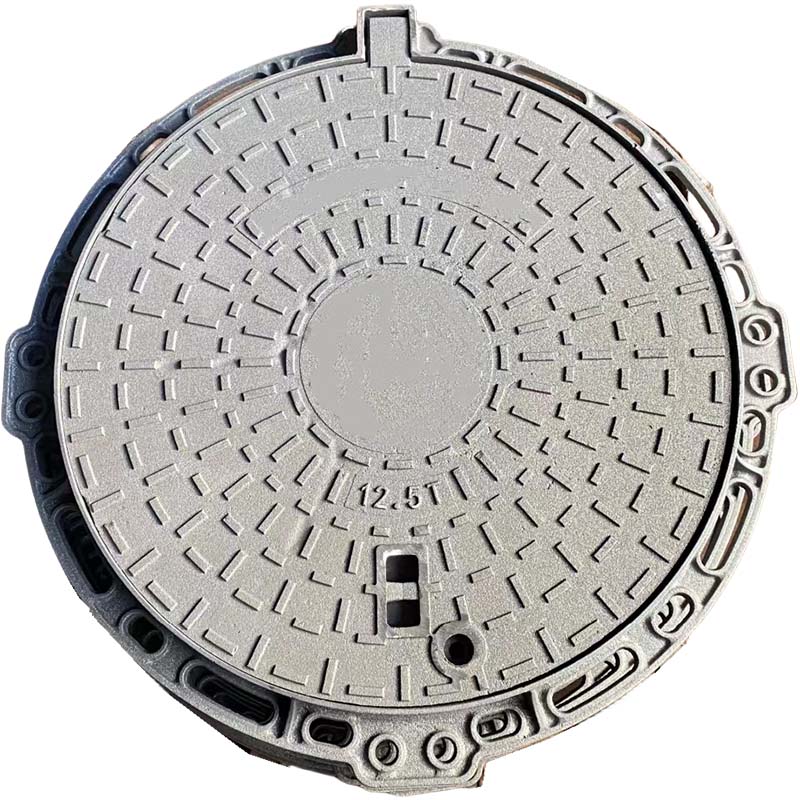

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025