butterfly valve ss316

Understanding the Butterfly Valve A Focus on SS316 Material

Butterfly valves are a type of quarter-turn valve widely used in various industries for regulating flow. They are known for their simplicity, compact design, and efficiency in controlling large volumes of fluid. Among the many materials used for these valves, SS316, or stainless steel 316, stands out as a preferred choice due to its excellent corrosion resistance and durability, making it an ideal option for a wide range of applications.

What is a Butterfly Valve?

A butterfly valve consists of a rotating disk or vane that is positioned in the center of the pipe. When the handle or actuator is turned, the disk rotates on a shaft, either completely opening or closing the flow path. This design allows for a minimal pressure drop when the valve is open, which is particularly beneficial in systems requiring a steady flow.

With low manufacturing costs and ease of installation, butterfly valves are popular in various sectors including water treatment, chemical processing, oil and gas, and food and beverage industries. Their versatility and reliability make them indispensable tools in fluid control systems.

Advantages of SS316 Butterfly Valves

1. Corrosion Resistance SS316 stainless steel is an alloy that includes molybdenum, providing superior resistance to corrosion when compared to other stainless steels, such as SS304. This characteristic is particularly important in industries dealing with harsh chemicals or seawater, where corrosion can lead to structural failures and costly repairs.

2. High-Temperature Resistance SS316 can withstand relatively high temperatures, making it suitable for applications involving steam or other high-temperature fluids. The ability to maintain integrity at elevated temperatures further enhances the reliability of butterfly valves made from this material.

butterfly valve ss316

3. Mechanical Strength The mechanical properties of SS316 provide excellent strength and durability, allowing for the design of thinner valves without sacrificing performance. This results in lighter and more manageable equipment, which is an advantage for installation and maintenance.

4. Hygienic Properties SS316 is widely used in food and pharmaceutical industries due to its hygienic properties. The smooth surface finish of stainless steel minimizes the risk of bacteria accumulation, ensuring that the flow of products remains uncontaminated.

5. Versatility Butterfly valves made from SS316 can be used in various applications ranging from water supply systems to chemical processing plants. Their ability to handle different media, including gases and liquids, adds to their versatility.

Application and Installation Considerations

When selecting SS316 butterfly valves, it is important to consider the specific requirements of the application. Factors such as temperature, pressure, and the type of fluid being handled can influence the performance of the valve. Proper installation is also crucial; butterfly valves should be positioned correctly to ensure optimal operation. Usually, they are installed in a horizontal position, but depending on the system design, vertical installations can also be feasible.

Moreover, regular maintenance checks are essential to ensure the longevity and effective operation of butterfly valves. This includes inspecting seals and actuators, as well as monitoring for any signs of wear or corrosion.

Conclusion

In summary, SS316 butterfly valves represent a reliable and efficient solution for fluid control across industrial applications. Their exceptional corrosion resistance, strength, and hygienic properties make them an ideal choice, especially in challenging environments. As industries continue to evolve, the demand for such durable and effective components will only grow, making SS316 butterfly valves a staple in the world of fluid dynamics. Whether in chemical processing or water management, the butterfly valve remains an essential element in the effective control of fluid systems.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

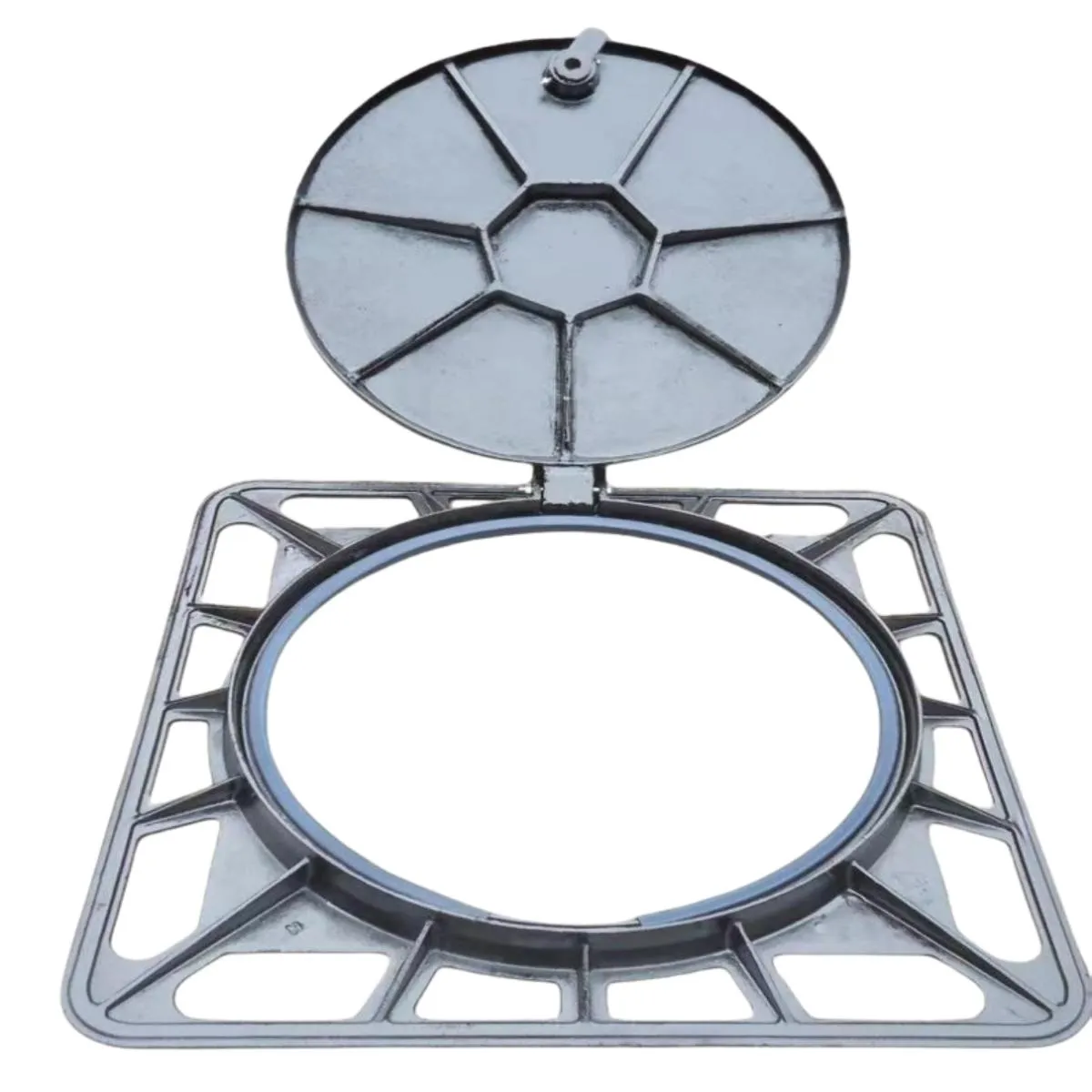

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025