PN16 Butterfly Valve Specifications and Applications for Fluid Control Systems

Understanding Butterfly Valve PN16 A Comprehensive Overview

Butterfly valves are essential components in various industrial applications, particularly in systems requiring the regulation and isolation of flow. One common specification within this range is the PN16 rating, which designates the pressure class of the valve. Understanding the significance of a PN16 butterfly valve, its design, applications, and advantages can help professionals select the right valve for their specific needs.

What is a Butterfly Valve?

A butterfly valve is a type of quarter-turn valve that uses a rotating disc to regulate flow. The valve is constructed with a circular body, a disc that pivots in the center, and an actuator. When the actuator turns the disc 90 degrees, it opens or closes the valve, allowing or stopping the flow of fluid through the pipeline. The streamlined design of butterfly valves makes them suitable for a variety of applications, as they can control large volumes of fluid with minimal pressure drop.

PN16 Specification Explained

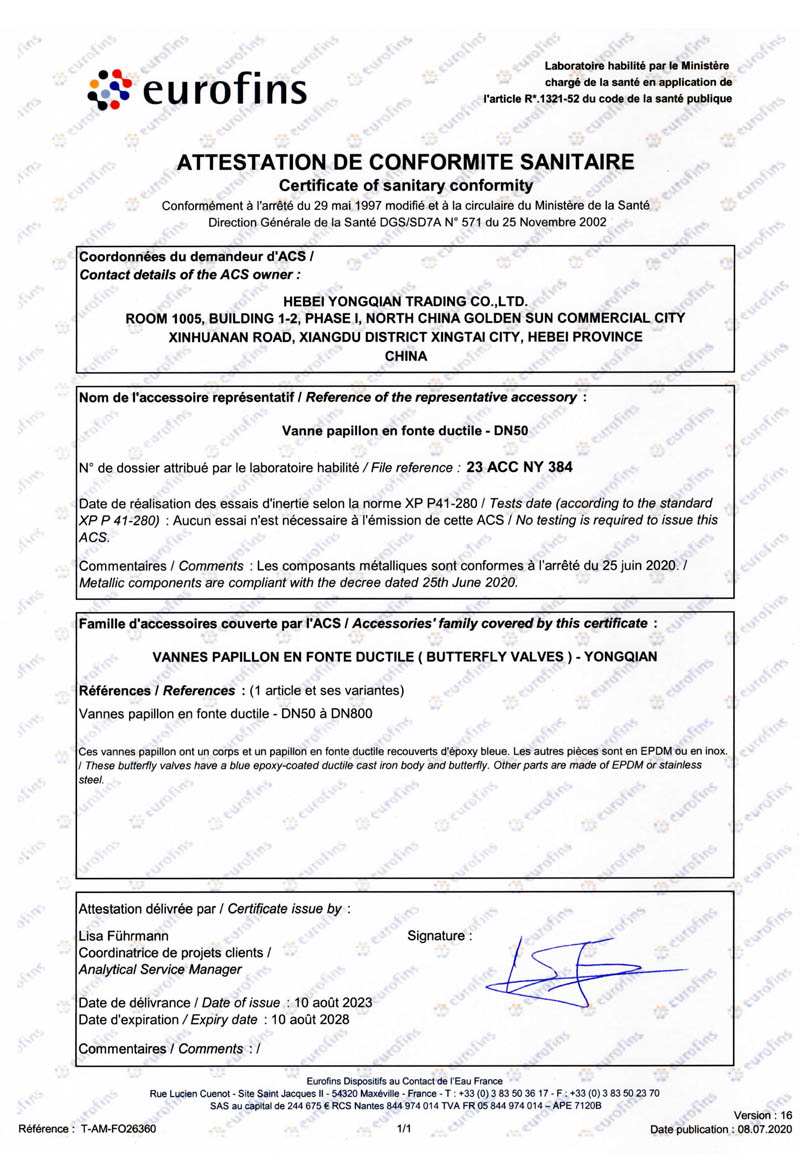

The PN in PN16 stands for Pressure Nominal, which indicates the valve's pressure rating. PN16 valves can operate safely at a maximum pressure of 16 bar (about 232 psi) at a standard temperature of 20°C (68°F). This certification implies that the butterfly valve is suitable for various applications, including water supply, sewage treatment, and fire protection systems.

Construction Features

A PN16 butterfly valve is typically manufactured from ductile iron, stainless steel, or other corrosion-resistant materials, depending on the application requirements. Key components include

1. Disc The disc is designed to be lightweight yet robust, allowing for quick operation. It can be made from different materials such as EPDM, nitrile, or PTFE, taking into account the flow medium.

2. Body The body of the valve is integral to its strength and durability. A PN16 rated body is designed to handle high pressures and is often coated for additional resistance to corrosion and wear.

3. Sealing Mechanism The sealing surface is crucial for preventing any leakage. Many butterfly valves come with elastomeric seals or can have a laminated PTFE seat for higher performance and longevity.

4. Actuation Butterfly valves can be manually operated or equipped with actuators, which may be electric, pneumatic, or hydraulic. The choice of actuation method depends on the operational requirements and constraints of the installation.

Applications

butterfly valve pn16

PN16 butterfly valves are versatile and widely used across various industries

- Water Treatment Plants These valves regulate water flow and isolate different sections of the treatment process. - Chemical Processing They are used for controlling the flow of aggressive chemicals due to their durable construction materials.

- Fire Protection Systems Butterfly valves play a crucial role in controlling water flow in sprinkler and fire suppression systems

.- Heating and Cooling Systems In HVAC applications, they help manage fluid flow for heating and cooling processes.

Advantages of Butterfly Valves

Butterfly valves offer several advantages

1. Space-Saving Design Due to their compact design, butterfly valves require less space compared to gate or globe valves.

2. Low Pressure Drop Their streamlined flow path allows for better flow characteristics, ensuring minimal pressure drop.

3. Quick Operation The quarter-turn operation enables swift opening and closing, making them ideal for processes requiring fast response times.

4. Cost-Effective Generally, butterfly valves are more cost-effective than many other valve types, both in initial costs and maintenance.

Conclusion

In summary, the PN16 butterfly valve is a reliable and versatile option for various industries needing flow control and isolation. Its design and pressure rating make it appropriate for demanding applications, while its features and benefits highlight its importance in efficient fluid management. When selecting a butterfly valve, it is crucial to consider the specific requirements of the application, including pressure, temperature, and the nature of the fluid, to ensure optimal performance and longevity of the valve.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025