butterfly valve dn300

Understanding the Butterfly Valve DN300 A Comprehensive Guide

The butterfly valve is a crucial component used in various industrial applications for regulating and controlling fluid flow. One of the notable sizes in the butterfly valve category is the DN300, which indicates a nominal diameter of 300 millimeters. This article aims to provide a comprehensive understanding of the DN300 butterfly valve, its construction, applications, advantages, and maintenance.

Construction of the Butterfly Valve DN300

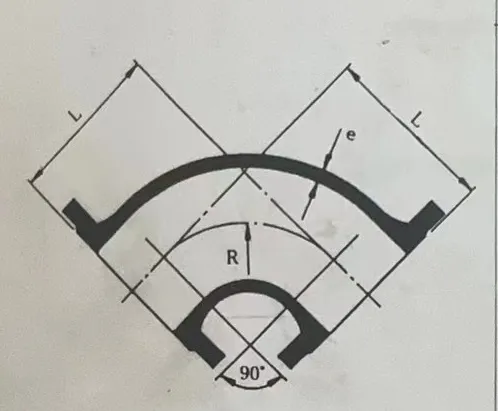

The butterfly valve features a simple design consisting of a disc, a shaft, and a body. The disc is mounted on a shaft and positioned within the valve body, which is typically made from materials like cast iron, stainless steel, or PVC, depending on the application. The key characteristic of the butterfly valve is its disc, which rotates about the shaft to either block or allow flow. When the disc is parallel to the flow, the valve is fully open; when perpendicular, it is fully closed. The DN300 designation signifies that the valve has an opening diameter of 300 mm, making it suitable for various industrial applications.

Applications of Butterfly Valve DN300

The DN300 butterfly valve is widely utilized in industries such as water supply, wastewater treatment, chemical processing, and oil and gas. These valves are ideal for handling large volumes of liquids and gases, making them essential in systems where efficient flow control is crucial. In water treatment plants, for instance, DN300 butterfly valves help regulate the flow of water through pipelines, ensuring that the plant operates effectively. In the chemical industry, these valves manage the flow of various fluids, helping to maintain optimal conditions for chemical reactions.

Advantages of the Butterfly Valve DN300

butterfly valve dn300

One of the main advantages of the DN300 butterfly valve is its compact design, which allows for easy installation in tight spaces. Additionally, these valves offer quick operation, requiring only a quarter turn to open or close fully. This speed is beneficial in emergency situations where rapid flow control is essential. Another significant advantage is the reduced pressure drop across the valve, which contributes to energy savings and enhances overall system efficiency.

Durability is another key feature of the DN300 butterfly valve. With proper material selection, these valves can withstand high pressures and temperatures, making them suitable for challenging environments. Furthermore, the simplicity of their design leads to lower maintenance costs, as there are fewer parts that can wear out or fail.

Maintenance of Butterfly Valve DN300

While the DN300 butterfly valve is designed for durability and low maintenance, regular inspection is necessary to ensure optimal performance. Users should check for signs of wear on the disc and seals, as well as any signs of corrosion on the valve body. Lubricating the shaft periodically can also prevent stiffness and ensure smooth operation.

Additionally, it’s important to monitor the actuator, whether it is manual or automated, to confirm that it is functioning correctly. Regular maintenance not only extends the lifespan of the valve but also ensures reliable operation, which is critical in any industrial process.

Conclusion

In summary, the butterfly valve DN300 is a vital instrument in various industrial applications, providing efficient flow control and reliable performance. Its compact design, quick operation, and durability make it a favored choice among engineers and operators alike. By understanding its construction, applications, advantages, and maintenance practices, users can significantly enhance their operational efficiency and ensure the longevity of their systems. Investing in quality butterfly valves like the DN300 ultimately contributes to improved productivity and reduced operational costs in the long run.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025