DIN 125 Butterfly Valve Specifications and Applications for Fluid Control Systems

Understanding the Butterfly Valve DN125 A Comprehensive Overview

The butterfly valve is a crucial component utilized in various industrial processes, particularly in the regulation and control of fluid flow. Among its various sizes, the DN125 butterfly valve has gained notable attention due to its versatility and efficiency. This article explores the functionality, applications, advantages, and considerations associated with the DN125 butterfly valve.

What is a Butterfly Valve?

A butterfly valve operates on a simple mechanism using a rotating disc to control the flow of fluid. When the valve is closed, the disc is perpendicular to the flow, effectively blocking it. Conversely, when the valve is opened, the disc rotates parallel to the flow, allowing maximum passage of fluid. This design enables quick opening and closing, making it an efficient choice for many applications.

Specifications of DN125 Butterfly Valve

The DN in DN125 stands for Diameter Nominal, which refers to the valve's nominal diameter of 125 millimeters. This size is suitable for a range of piping systems in various industries including water supply, HVAC systems, and process engineering. Typically, DN125 butterfly valves are available in different materials such as cast iron, stainless steel, and plastic, allowing for compatibility with a wide variety of fluids, from water to chemical solvents.

Applications of DN125 Butterfly Valves

The applications of DN125 butterfly valves are extensive

. They are widely used in1. Water Treatment Plants These valves help control the flow of water throughout the treatment process, ensuring the efficient operation of various machinery and systems. 2. HVAC Systems In heating, ventilation, and air conditioning systems, DN125 butterfly valves are crucial for regulating air and fluid flow, contributing to energy efficiency and temperature control.

3. Agricultural Irrigation Butterfly valves manage water flow in irrigation systems, facilitating effective water management for crop production. 4. Chemical Processing The DN125 size allows for the handling of different chemical fluids, essential for industries involved in chemical manufacturing and those that require precise fluid control.

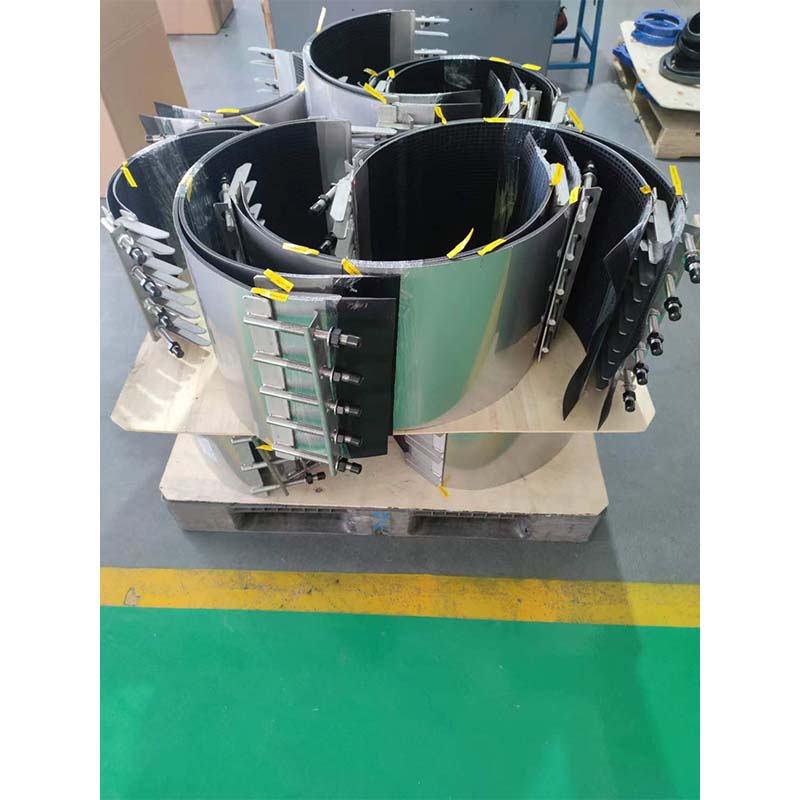

butterfly valve dn125

Advantages of DN125 Butterfly Valves

One of the most significant advantages of using DN125 butterfly valves is their compact design. They can fit into tight spaces where traditional valves might not be appropriate. Additionally, their lightweight design makes installation and maintenance easier.

Another benefit is the low pressure drop across the valve, which enhances system efficiency. Due to their simple construction, they also require low maintenance and can endure high flow rates, making them cost-effective over time.

Considerations When Choosing a DN125 Butterfly Valve

When selecting a DN125 butterfly valve, several factors should be considered

1. Material Selection Depending on the fluid being handled, appropriate materials should be chosen to prevent corrosion and ensure longevity. 2. Pressure Rating It’s essential to ensure that the selected valve can handle the maximum pressure of the system to avoid failures.

3. Actuation Type Butterfly valves can be manually operated or automated. For larger systems, pneumatic or electric actuators might be more suitable, providing efficiency and control.

4. Flow Characteristics Understanding the flow requirements can help in selecting the right valve design, whether for on-off control or throttling applications.

Conclusion

In conclusion, the DN125 butterfly valve is an extremely valuable component for various industrial applications, offering a combination of versatility, efficiency, and cost-effectiveness. By understanding its functionality, advantages, and considerations, engineers and technicians can make informed decisions when integrating these valves into fluid control systems. As industries continue to innovate and evolve, butterfly valves, including the DN125 model, will undoubtedly remain pivotal in advancing fluid-handling technologies.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025