150 mm Butterfly Valve Specifications and Applications for Industrial Use

Understanding the 150 mm Butterfly Valve Design, Functionality, and Applications

Butterfly valves are a pivotal component in modern fluid control systems, offering a reliable mechanism to regulate the flow of liquids and gases. Among the various sizes available, the 150 mm butterfly valve stands out for its versatility and efficiency. In this article, we will delve into the design, functionality, and applications of the 150 mm butterfly valve, highlighting its importance in various industries.

Design and Structure

The 150 mm butterfly valve features a simple yet effective design. It consists of a disc (the butterfly) that rotates around a central axis within the valve body. The disc is connected to a stem, which is actuated either manually or automatically through electric or pneumatic means. The valve's body is typically made from durable materials such as stainless steel, cast iron, or plastic, depending on the application and the fluid it will handle.

One of the key design elements of the butterfly valve is its compact size. The 150 mm diameter allows for installation in tight spaces, making it an ideal choice for various applications where space is at a premium. Additionally, the valve's lightweight nature reduces the structural load on piping systems and supports, leading to easier installation and maintenance.

Functionality

The primary function of the 150 mm butterfly valve is to regulate flow. When the valve is in the closed position, the disc is perpendicular to the flow direction, creating a tight seal that prevents leakage. As the disc rotates to an open position, it allows fluid to flow through the valve. The degree to which the valve is opened can be precisely controlled, offering excellent flow regulation.

Butterfly valves are known for their quick and easy operation, with a full open-to-close rotation typically taking less than a quarter turn (90 degrees). This feature is particularly beneficial in applications requiring rapid shut-off capabilities, such as in emergency situations where immediate action is necessary.

Moreover, due to their streamlined design, butterfly valves have low pressure drops compared to other valve types. This makes them suitable for applications where energy efficiency and flow rate optimization are critical considerations.

Applications

butterfly valve 150 mm

The versatility of the 150 mm butterfly valve makes it suitable for a wide range of applications across various industries

. Some of the most common applications include1. Water Treatment Plants In water supply and treatment systems, butterfly valves control the flow of water, ensuring efficient distribution and treatment processes.

2. Oil and Gas Butterfly valves handle crude oil and natural gas in pipelines, providing reliable flow control in demanding environments.

3. Chemical Processing The chemical industry often relies on 150 mm butterfly valves to regulate the flow of various corrosive substances, thanks to their resilient materials and effective sealing capabilities.

4. HVAC Systems In heating, ventilation, and air conditioning systems, these valves help manage airflow, contributing to energy efficiency and comfort in indoor environments.

5. Food and Beverage The sanitary design of certain butterfly valves allows them to be used in the food and beverage industry, ensuring safe and hygienic flow control.

Conclusion

The 150 mm butterfly valve is a crucial component in numerous industries, known for its compact design, efficient functionality, and versatility. Whether controlling water flow in treatment plants, regulating oil in pipelines, or managing airflow in HVAC systems, this type of valve plays an essential role in ensuring operational efficiency and safety. As industries continue to evolve and grow, the innovations surrounding butterfly valve technology, including automation and advanced materials, will further enhance their application scope, paving the way for more efficient fluid management solutions in the future.

In summary, understanding the characteristics and applications of the 150 mm butterfly valve is vital for engineers, project managers, and technicians alike, as it equips them with the knowledge necessary to select the right valve for their specific needs, ultimately leading to enhanced system performance and reliability.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

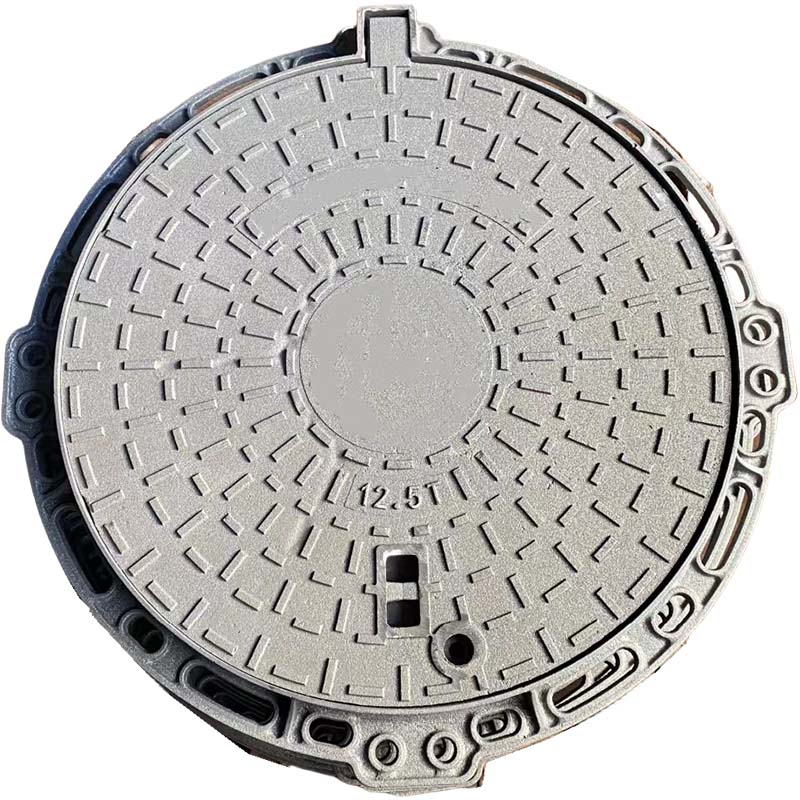

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025