Exploring the Benefits and Applications of Butterfly Ball Valves in Fluid Systems

The Butterfly Ball Valve An Overview

The butterfly ball valve is a vital component in modern fluid control systems, offering a unique blend of functionality, efficiency, and ease of operation. This valve is designed to regulate the flow of liquids and gases in various industrial processes, and its robust construction and design make it a popular choice in countless applications, from water treatment to chemical processing.

At the core of the butterfly ball valve is its distinctive mechanism, which combines the features of a traditional ball valve and a butterfly valve. Unlike a standard ball valve that utilizes a spherical closure element to control flow, the butterfly ball valve employs a disc-shaped closure that rotates around a central axis. When the handle is turned, the disc opens or closes the flow path, allowing for quick and efficient control. This design ensures minimal pressure drop across the valve, contributing to energy savings in system operations.

One of the primary advantages of the butterfly ball valve is its versatility

. It can handle a wide range of flow rates and pressure levels, making it suitable for various industries, including oil and gas, water management, and HVAC systems. The compact design of the valve also means it requires less space than traditional valve designs, making it ideal for installations in confined areas.butterfly ball valve

In terms of materials, butterfly ball valves are available in various options, including stainless steel, carbon steel, and plastic, enabling customization based on the specific needs of the application. The choice of material influences factors such as durability, resistance to corrosion, and overall service life. For instance, stainless steel valves are preferred in environments where they may be exposed to aggressive chemicals or high levels of humidity.

The operation of the butterfly ball valve is straightforward. It can be actuated manually, using a lever or wheel, or mechanically, employing electric or pneumatic actuators for automation. Automated systems often enhance efficiency and provide better flow control, especially in large-scale industrial operations where precision is crucial. Additionally, the position of the valve can be monitored using sensors, ensuring optimal performance and safety.

Safety is another significant consideration when using butterfly ball valves. They are designed to feature a fail-safe mechanism, ensuring that in the event of a power failure or mechanical malfunction, the valve will either fully open or close, preventing unintended flow. This safety feature, combined with proper maintenance and regular inspections, contributes to the reliable operation of systems that utilize butterfly ball valves.

In conclusion, the butterfly ball valve stands out as an efficient and effective solution for controlling fluid flow in a wide array of applications. Its unique design, combined with material versatility and ease of operation, makes it a preferred choice among engineers and procurement professionals. As industries continue to evolve and prioritize efficiency and safety, the butterfly ball valve is likely to remain a key player in the realm of fluid control technology, adapting to meet the demands of the future.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

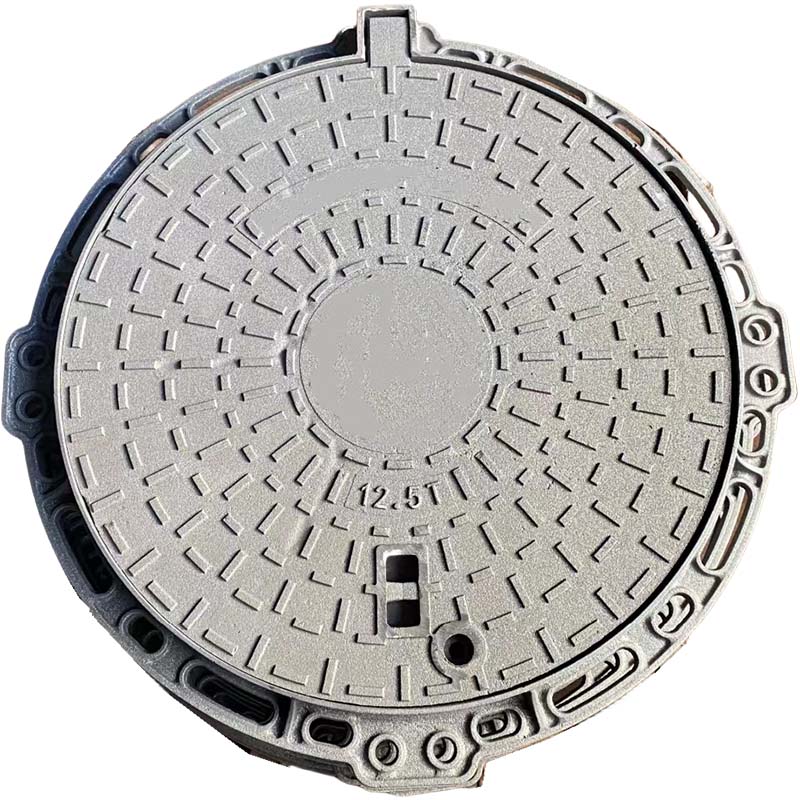

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025