Butterfly Valve with Positioner - Precision Control for Fluid Systems

Understanding Butterfly Valves with Positioners

Butterfly valves play a crucial role in various industrial applications due to their simple design, ease of use, and cost-effectiveness. These valves are designed to regulate the flow of fluids within a pipeline and are particularly favored for their quick operation and compact size. When paired with a positioner, butterfly valves can achieve enhanced performance and precision in flow control.

Understanding Butterfly Valves with Positioners

Adding a positioner to a butterfly valve system elevates its functionality significantly. A valve positioner adjusts the valve's position in response to control signals from a control system. This combination allows for precise control over the opening and closing of the valve, ensuring that the desired flow rate is maintained accurately. This level of control is essential in applications where consistent flow is critical to operational efficiency and safety.

butterfly valve with positioner

In industrial settings, a typical positioner operates using a feedback loop. It receives signals from sensors indicating the current flow rate or the valve's position. If there is a discrepancy between the desired and actual position, the positioner adjusts the valve accordingly. This dynamic adjustment capability greatly enhances the operational reliability of systems where flow variations can lead to process disruptions.

The advantages of using butterfly valves with positioners are manifold. Firstly, the responsiveness of the valve to changes in process conditions minimizes the risk of overpressure and enhances safety in the system. Secondly, the precise control provided by the positioner leads to improved energy efficiency since the system can operate at optimal flow rates. Additionally, the simplicity of the butterfly valve design means that maintenance is generally less complex and less expensive than other types of valves.

However, the integration of valve positioners also requires careful consideration during design and implementation. Selecting the right positioner involves assessing the specific operational conditions, including the type of media being controlled, temperature, and pressure ranges. Furthermore, compatibility between the positioner and the valve must be ensured to maximize effectiveness.

In conclusion, butterfly valves coupled with positioners represent a powerful solution for managing fluid flow in various industries. The synergy between the valve’s design and the positioner’s control capabilities allows for enhanced precision, efficiency, and safety. As industries continue to advance technologically, the application of butterfly valves with integrated positioners will likely grow, making them increasingly integral to modern process control systems. When choosing such a system, it is essential to consider the specific needs of your application to achieve the best results and ensure operational success.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

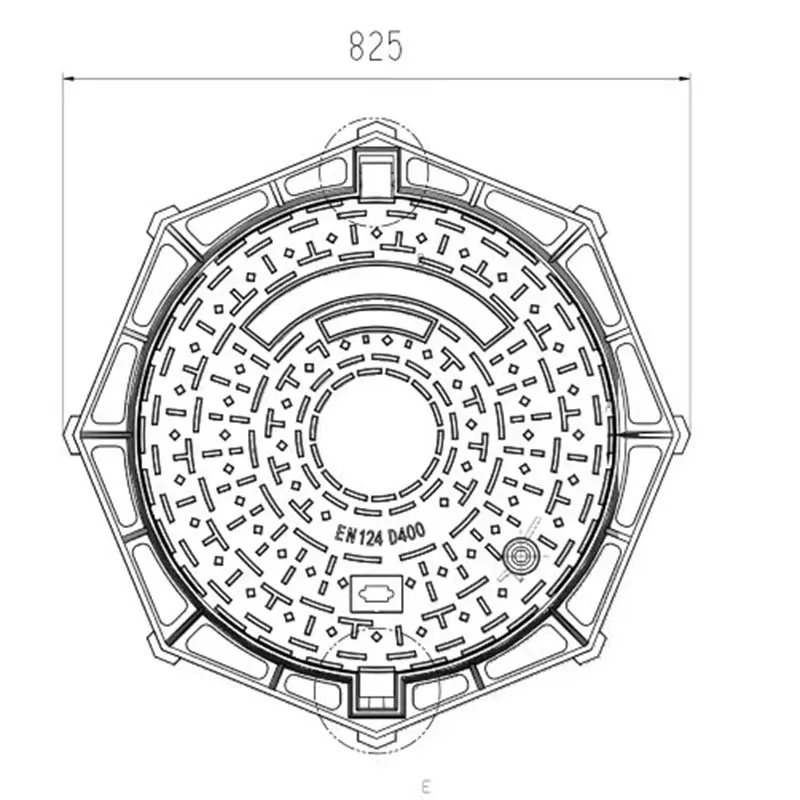

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025