Brass Air Release Valve - Durable & Efficient Solutions

The Importance of Brass Air Release Valves in Fluid Systems

Brass air release valves play a critical role in managing fluid systems, particularly in water and wastewater applications. These small yet essential components are designed to expel trapped air from pipelines, ensuring the efficient and safe operation of various systems. Understanding their function, benefits, and applications can provide valuable insights for engineers and operators alike.

What is a Brass Air Release Valve?

A brass air release valve is a mechanical device installed at high points in a pipeline. Its primary function is to release any accumulated air that can hinder fluid flow. Air entrapment can create several issues such as reduced flow efficiency, increased pressure on the pipeline, and even potential system failure. By automatically venting air from the system, these valves help maintain optimal performance.

Benefits of Brass Construction

Brass is an ideal material for air release valves due to its durability and resistance to corrosion. Unlike plastic or other metals, brass can withstand high temperatures and pressures typically associated with fluid systems. Its robust nature ensures a longer lifespan, reducing the need for frequent replacements. Additionally, brass offers excellent sealing capabilities, minimizing the risk of leaks and enhancing overall system reliability.

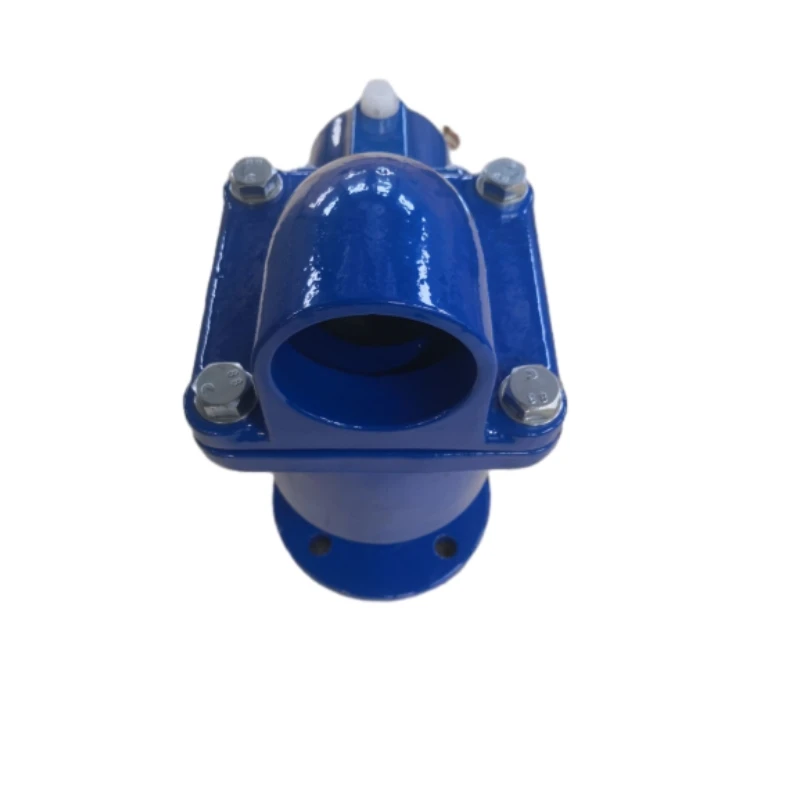

brass air release valve

Applications in Various Industries

Brass air release valves are widely used across various industries. In municipal water supply systems, they help manage pressure and prevent water hammer—a pressure surge that can cause severe damage to pipes. In HVAC systems, they allow for the removal of air pockets that can disrupt the heating or cooling cycle. Furthermore, in agricultural irrigation, these valves ensure that water flows smoothly to crops, maximizing efficiency and yield.

Installation and Maintenance Considerations

Proper installation of brass air release valves is crucial for their performance. They should be placed at strategic high points within the piping system to ensure effective air removal. Regular maintenance is also important; operators should check the valves periodically for signs of wear or malfunction. By ensuring that these valves are functioning correctly, operators can prevent costly downtime and repairs.

Conclusion

In summary, brass air release valves are vital components in fluid systems, offering significant benefits such as enhanced efficiency and system reliability. Their robust construction and ability to prevent air entrapment make them indispensable in various applications, from municipal water supplies to agricultural irrigation. As the demand for efficient fluid management continues to grow, the role of brass air release valves will remain critical in ensuring optimal performance across multiple industries. Whether for new installations or retrofits, investing in high-quality brass air release valves is a smart decision for any fluid system engineer or operator.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025