ball valve butterfly valve

Ball Valve vs. Butterfly Valve A Comprehensive Comparison

When it comes to controlling the flow of liquids and gases in various applications, two popular types of valves often come into consideration ball valves and butterfly valves. Each of these valves has its unique attributes, advantages, and limitations, making them suitable for different scenarios. In this article, we will explore the characteristics of both types of valves, helping you make an informed decision for your specific needs.

Design and Structure

Ball Valve Ball valves are designed with a hollow, perforated, and pivoting ball that allows or blocks the flow of fluid. The ball is positioned within the valve body, with the flow passing through an orifice in the center. When the valve handle is turned, the ball rotates 90 degrees to either open or close the flow path. This simple yet effective design minimizes turbulence and pressure drops.

Butterfly Valve Butterfly valves, on the other hand, utilize a flat circular disc that rotates around a central axis to control flow. The disc is mounted on a shaft and, when turned, either blocks or allows fluid to pass by creating a path through the valve body. Butterfly valves are usually lighter and more compact compared to ball valves, making them suitable for applications where space is limited.

Flow Control and Efficiency

Ball Valve One of the primary advantages of ball valves is their ability to provide a tight seal. When fully opened, a ball valve offers minimal resistance to flow, allowing for a smooth and uninterrupted passage. This makes ball valves ideal for applications requiring full flow or shut-off capabilities, such as in gas and liquid systems under high pressure.

Butterfly Valve While butterfly valves are efficient in regulating flow, they are not as effective at providing tight seals as ball valves. The flow path through a butterfly valve can cause turbulence, especially when partially opened, which can lead to pressure drops. However, they are particularly well suited for throttling applications and large-diameter piping systems due to their lower cost and lightweight construction.

Cost Considerations

ball valve butterfly valve

When it comes to pricing, butterfly valves tend to be more economical than ball valves. The manufacturing process for butterfly valves is simpler, and their lightweight design can result in lower installation costs, especially for large-scale applications. However, ball valves offer superior performance and durability, which may justify the higher initial investment in certain high-pressure or critical applications.

Applications

Ball valves are commonly used in industries where a fast shut-off is necessary, such as oil and gas, chemical processing, and water treatment. Their ability to withstand high pressures and temperatures makes them suitable for a variety of demanding environments.

Butterfly valves are frequently employed in applications involving large volumes of fluid, such as wastewater treatment, HVAC systems, and food processing. Their compact design and ease of operation make them a popular choice in situations where space is a constraint.

Maintenance and Longevity

Both ball valves and butterfly valves require regular maintenance to ensure optimal performance. Ball valves typically have fewer moving parts, which can reduce maintenance needs. They are also less prone to wear and tear due to their sealing mechanism. Butterfly valves, while more susceptible to wear due to the disc's constant contact with the flow, can be easier to access for repairs or replacements.

Conclusion

In summary, the choice between a ball valve and a butterfly valve largely depends on the specific application and requirements. Ball valves excel in providing tight shut-off and are ideal for high-pressure situations, whereas butterfly valves are favored for their compact design and cost-effectiveness in large-scale applications. Understanding the distinctions between these two types of valves can guide you in selecting the right valve for your project, ensuring efficient flow control and operational success. Whether you prioritize performance, cost, or application suitability, both ball valves and butterfly valves hold important places in the world of fluid management.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

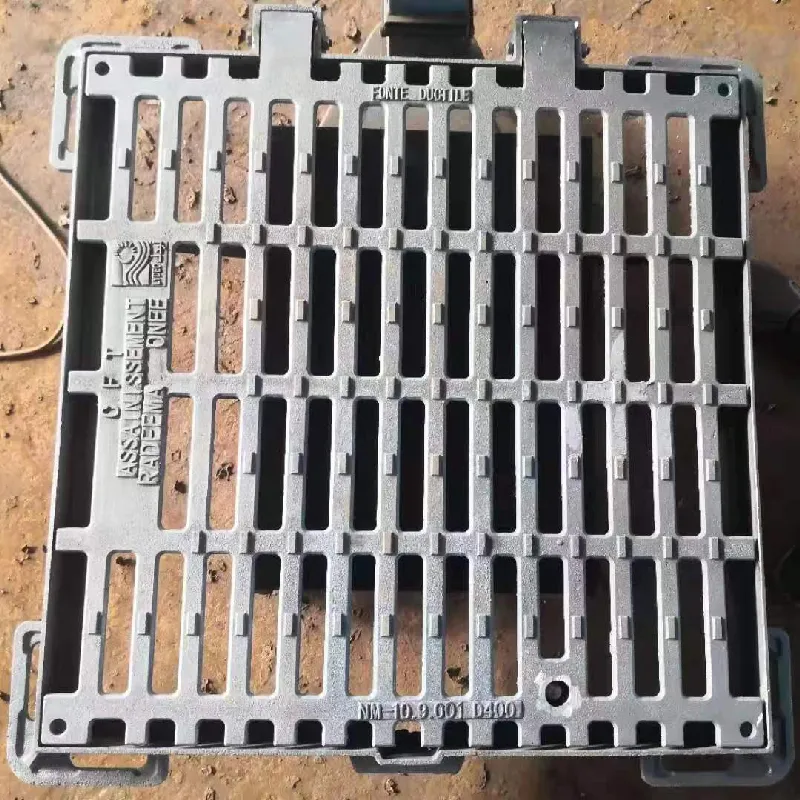

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025