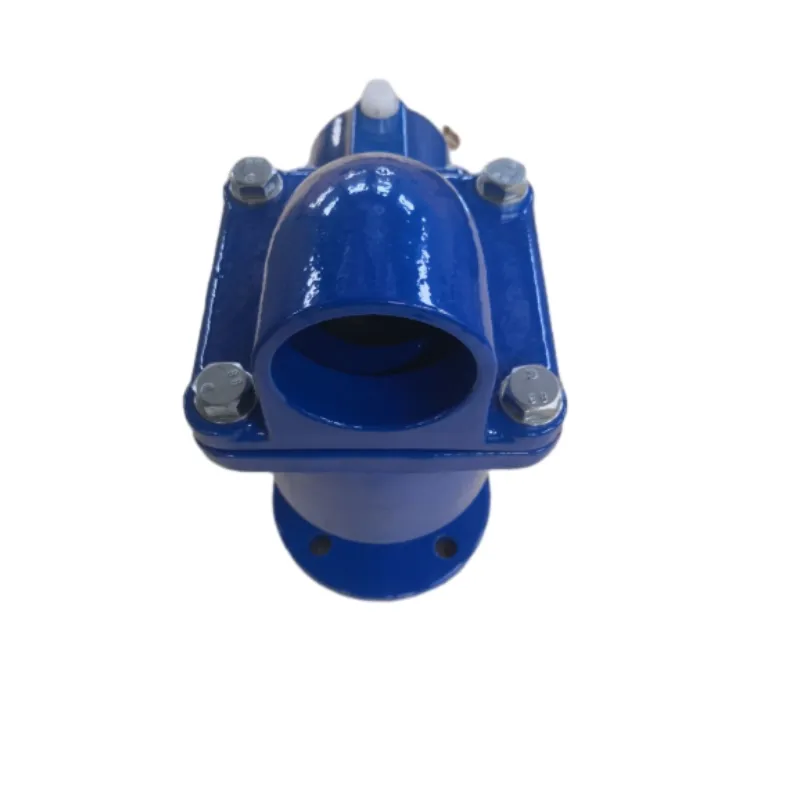

air and vacuum relief valve

Understanding Air and Vacuum Relief Valves Essential Components for Fluid Management

Air and vacuum relief valves play a critical role in various fluid management systems, ensuring that pipelines and tanks operate efficiently without risking damage due to pressure imbalances. These valves are essential for maintaining the integrity of systems that transport liquids and gases, particularly in industries such as water treatment, oil and gas, and chemical manufacturing.

The Function of Air and Vacuum Relief Valves

Air and vacuum relief valves serve two primary functions they allow air to enter a system to prevent vacuum conditions and enable the release of excess pressure to maintain optimal operating conditions. In fluid transport systems, especially those dealing with liquids, pressure imbalances can lead to significant problems.

When liquid is transported through a pipeline, it can create a vacuum if there is a sudden drop in flow. This vacuum can cause the pipe to collapse, which can lead to leaks or rupture. Conversely, if excessive pressure builds up within a system (due to thermal expansion, for example), it can cause catastrophic failures. The relief valve mitigates these risks by regulating air pressure, ensuring the system can maintain a balanced environment.

Types of Air and Vacuum Relief Valves

There are different types of air and vacuum relief valves, each designed for specific applications

1. Air Relief Valves These valves are designed to allow air to enter the system when a vacuum condition is detected. They open automatically to equalize pressure and close once the normal atmospheric pressure is restored.

2. Vacuum Relief Valves Conversely, vacuum relief valves open to release air and prevent vacuum conditions. This is vital in applications where liquids could potentially create a vacuum during transport or storage.

3. Combination Valves Some valves are designed to perform both functions, allowing for air intake and vacuum relief management within one unit. This dual function can simplify installation and maintenance while providing comprehensive pressure management.

Key Considerations When Selecting Air and Vacuum Relief Valves

air and vacuum relief valve

When selecting the appropriate air and vacuum relief valve for a specific application, several factors must be considered

1. System Requirements Understanding the operational conditions, including the types of fluids handled and pressure ranges, is crucial. This ensures that the selected valve can withstand the environmental demands.

2. Flow Capacity The valve must have an adequate flow capacity to handle the expected volume of air or liquid during operational fluctuations.

3. Material Compatibility The materials of the valve should be compatible with the fluids it will come into contact with to avoid corrosion or degradation over time.

4. Installation Location The installation environment can affect the valve's performance. Outdoor installations may require additional protective measures against weather and environmental factors.

5. Maintenance Needs Consider how easy the valve is to maintain. Valves that require frequent servicing can lead to increased downtime and operational costs.

The Importance of Regular Maintenance

Just like any other component in a fluid transport system, air and vacuum relief valves require regular maintenance to ensure continued functionality. Neglecting maintenance can lead to valve failure, resulting in potential operational disruptions, costly repairs, and even environmental hazards. Routine checks should include inspections for wear and tear, ensuring moving parts are operational, and verifying that seals are intact.

Conclusion

Air and vacuum relief valves are indispensable in maintaining the safety and efficiency of fluid management systems. Their ability to manage pressure fluctuations helps prevent catastrophic failures while ensuring the continuous flow of liquids. By understanding their functions, types, and selection criteria, industry professionals can make informed decisions that enhance the longevity and reliability of their systems. Regular maintenance of these valves further ensures that they function optimally, safeguarding operations against the potential perils of pressure imbalances.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025