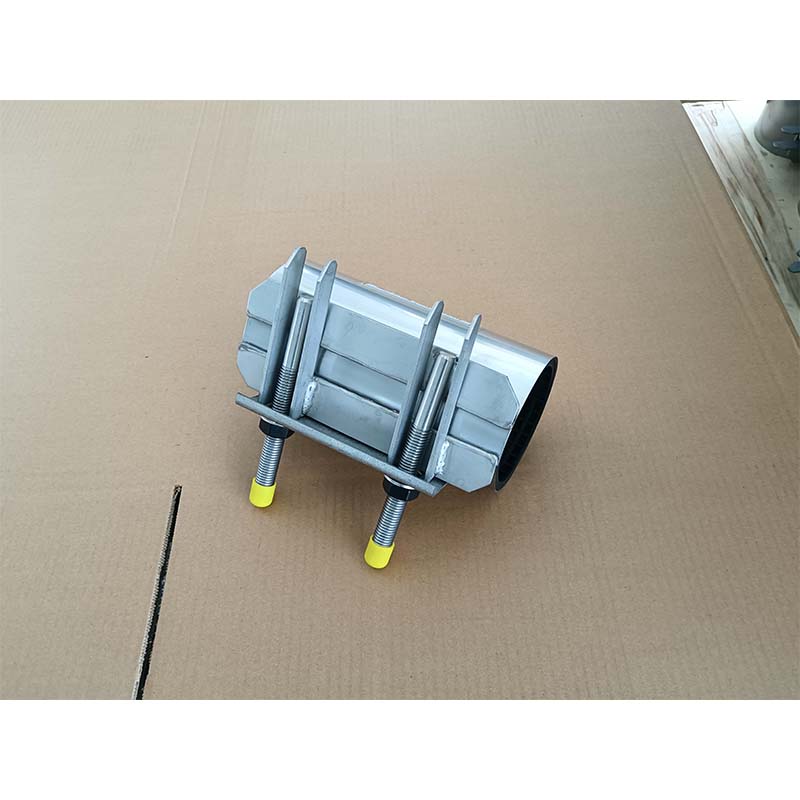

actuator operated butterfly valve

Actuator Operated Butterfly Valve An Overview

Butterfly valves are essential components in various industries, serving as effective flow control devices. Among the different types of butterfly valves, actuator operated butterfly valves stand out due to their automation capabilities, enhancing operational efficiency and reliability. This article delves into the features, benefits, and applications of actuator operated butterfly valves, providing a comprehensive understanding of their significance in modern industrial processes.

Understanding Butterfly Valves

A butterfly valve consists of a rotating disc or a vane that regulates the flow of fluid through a pipe. The design is characterized by its simplicity, which contributes to its lightweight and compact structure. When the disc is rotated a quarter turn, it either blocks the flow or allows it to pass through, making it an efficient mechanism for managing fluid flow. However, the introduction of actuators takes the functionality of butterfly valves to an advanced level.

What is an Actuator?

An actuator is a device that converts energy into mechanical motion. In the context of butterfly valves, actuators can be pneumatic, electric, or hydraulic, enabling automated control of the valve's position. This automation enhances the responsiveness of the valve, allowing for precise control of flow rates and improved safety protocols.

Benefits of Actuator Operated Butterfly Valves

1. Increased Efficiency Actuator operated butterfly valves can be integrated into automated systems, minimizing the need for manual operation. This reduces labor costs and enhances efficiency, especially in processes that require frequent adjustments.

2. Precision Control Actuators allow for fine-tuning of the valve position, ensuring that fluid flow is managed with high accuracy. This precision is crucial in processes where specific flow rates are necessary for optimal performance.

3. Remote Operation Actuator operated butterfly valves can be accessed remotely, facilitating control from a distance. This feature is particularly beneficial in hazardous environments where manual intervention may pose safety risks.

4. Quick Response Times The rapid actuation capability of these valves allows for swift adjustments, making them suitable for dynamic processes that require immediate response to changing conditions.

actuator operated butterfly valve

5. Reduced Wear and Tear By minimizing manual operation, the wear on valve components is significantly reduced, extending the valve's lifespan and reducing maintenance costs.

6. Versatility These valves can be used across a wide range of applications, including water treatment, chemical processing, HVAC systems, and oil and gas industries, making them versatile choices for industrial needs.

Applications of Actuator Operated Butterfly Valves

Actuator operated butterfly valves are employed in various settings due to their efficiency and reliability. Some prominent applications include

- Water and Wastewater Treatment These valves play a crucial role in controlling the flow of water and sludge, maintaining system balance and ensuring effective treatment processes.

- Chemical Processing In chemical plants, actuator operated butterfly valves manage the flow of corrosive substances, contributing to safety and efficiency in the manufacturing process.

- Food and Beverage Industry These valves are used for controlling flow rates during the production and processing of food products, ensuring compliance with safety standards.

- Oil and Gas In the oil and gas sector, these valves are integral in regulating flow in pipelines, helping to maintain safety and operational efficiency.

- HVAC Systems In heating, ventilation, and air conditioning, actuator operated butterfly valves are utilized to control airflow and optimize energy consumption.

Conclusion

Actuator operated butterfly valves represent a vital element in modern industrial applications, combining the benefits of traditional butterfly valve design with the advanced capabilities offered through automation. Their ability to deliver efficiency, precision, and remote operation has made them indispensable in numerous sectors. By integrating these valves into automated systems, industries can enhance productivity, reduce operational costs, and improve overall safety, positioning actuator operated butterfly valves as a key component in the future of fluid management.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025