8 inch PVC butterfly valve for efficient fluid control and durable performance in various applications

The 8% PVC Butterfly Valve A Comprehensive Overview

In the world of fluid control systems, valves are essential components used to regulate flow and pressure. Among various types of valves, the butterfly valve stands out for its simplicity, effectiveness, and versatility. One notable variant is the 8% PVC butterfly valve, which has gained popularity across various industries due to its unique characteristics and advantages.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn valve that uses a circular disc or butterfly to control the flow of fluid. When the valve is closed, the disc blocks the flow path, while rotating it a quarter turn opens the passage, allowing fluid to flow freely. Butterfly valves are popular because they are lightweight, have a compact design, and can be operated quickly, making them ideal for applications where speed and reliability are crucial.

Understanding PVC Material

PVC, short for polyvinyl chloride, is a widely used thermoplastic known for its strength, durability, and resistance to corrosive substances. This makes PVC an excellent material choice for various applications, especially in environments where metal valves might corrode or fail. In the context of butterfly valves, PVC offers a cost-effective solution without compromising performance. The 8% PVC butterfly valve refers to a specific design or model that utilizes PVC in its construction, making it lighter and more durable than traditional metal counterparts.

Features of the 8% PVC Butterfly Valve

1. Corrosion Resistance One of the most significant advantages of PVC valves is their resistance to chemical corrosion. This feature makes them suitable for transporting aggressive fluids often found in chemical processing, wastewater management, and agricultural applications.

2. Lightweight Design The use of PVC reduces the overall weight of the butterfly valve. This characteristic is particularly beneficial in installations where weight is a concern, such as in overhead piping systems or when transporting heavy valves to job sites.

8 inch pvc butterfly valve

3. Cost-Effectiveness Compared to metal valves, PVC butterfly valves are typically more affordable, making them an attractive option for budget-conscious projects. Additionally, their durability translates to lower maintenance and replacement costs over time.

4. Ease of Operation The design of the butterfly valve allows for quick opening and closing mechanisms. This feature is crucial in applications where precise flow control is necessary, ensuring efficient system performance.

5. Versatility The 8% PVC butterfly valve is versatile enough for various applications, including water treatment plants, HVAC systems, and irrigation systems. Its capacity to handle different types of fluids makes it suitable for diverse industries.

Applications

The applications for an 8% PVC butterfly valve are wide-ranging. In the water treatment industry, for instance, these valves are used to regulate the flow of water during various treatment processes. They are also commonly found in residential and commercial plumbing systems, where they control the flow of potable and wastewater.

In manufacturing, where precise flow control is necessary, the 8% PVC butterfly valve can be integrated into production lines, ensuring that materials and chemicals are transported efficiently. Agricultural applications, such as irrigation systems, benefit from the durability and resistance of PVC to corrosive fertilizers and pesticides.

Conclusion

The 8% PVC butterfly valve is an essential component in modern fluid control systems, offering a unique combination of lightweight construction, corrosion resistance, and cost-effectiveness. Its versatility makes it suitable for a broad spectrum of applications, from water treatment to industrial processes. As industries continue to seek innovative solutions for fluid management, the adoption of PVC butterfly valves is likely to grow, reinforcing their importance in the realm of valves and flow control technologies. By understanding the features and benefits of the 8% PVC butterfly valve, engineers and project managers can make informed decisions that enhance the efficiency and longevity of their systems.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

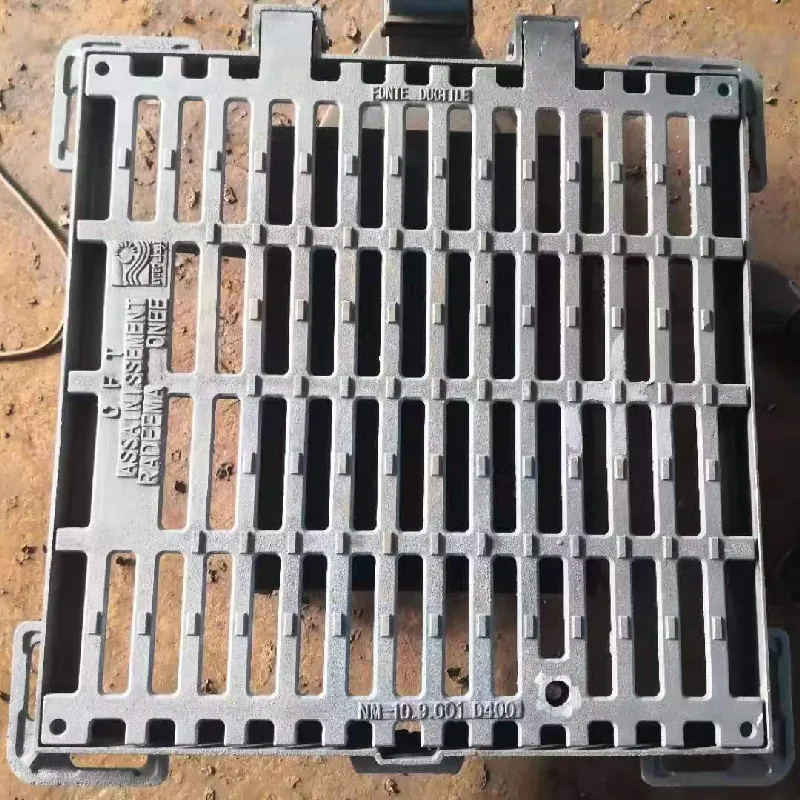

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025