Optimizing Flow Control with 48 Percent Butterfly Valve Design and Application

Understanding the 48% Butterfly Valve A Key Component in Fluid Control

In the realm of fluid control, valves play a critical role in regulating flow and pressure in various systems. Among the various types of valves, the butterfly valve has gained significant popularity due to its efficient design and versatility. This article delves into the intricacies of the butterfly valve, particularly focusing on the 48% butterfly valve, exploring its construction, applications, advantages, and maintenance considerations.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn valve that uses a rotating disc to control the flow of fluid. When the valve is closed, the disc is positioned perpendicular to the flow, effectively blocking it. Conversely, when the valve is open, the disc is parallel to the flow, allowing for unrestricted fluid passage. This simple yet effective mechanism makes butterfly valves suitable for a wide range of applications, particularly in large-scale systems where quick operation and minimal pressure drop are essential.

The 48% Butterfly Valve Design

The term 48% butterfly valve often refers to a specific design or application specification. This designation may indicate that the valve has a particular size or a design element that optimally allows 48% of the flow area to be utilized. The construction of a butterfly valve typically includes a disc, a stem, and a body. The disc is the primary component responsible for flow regulation, while the body houses the entire assembly. The 48% designation ensures that the valve effectively manages fluid flow in systems that require precise control without significant turbulence or pressure loss.

Applications of the 48% Butterfly Valve

The versatility of the 48% butterfly valve makes it suitable for various industries, including

1. Water Treatment Butterfly valves are often employed in water treatment plants to control the flow of water through various stages of purification and distribution.

2. Chemical Processing In chemical plants, these valves help manage corrosive fluids and gases, allowing for controlled processing and mixing.

3. HVAC Systems In heating, ventilation, and air conditioning systems, butterfly valves regulate airflow, ensuring optimal temperature and efficiency.

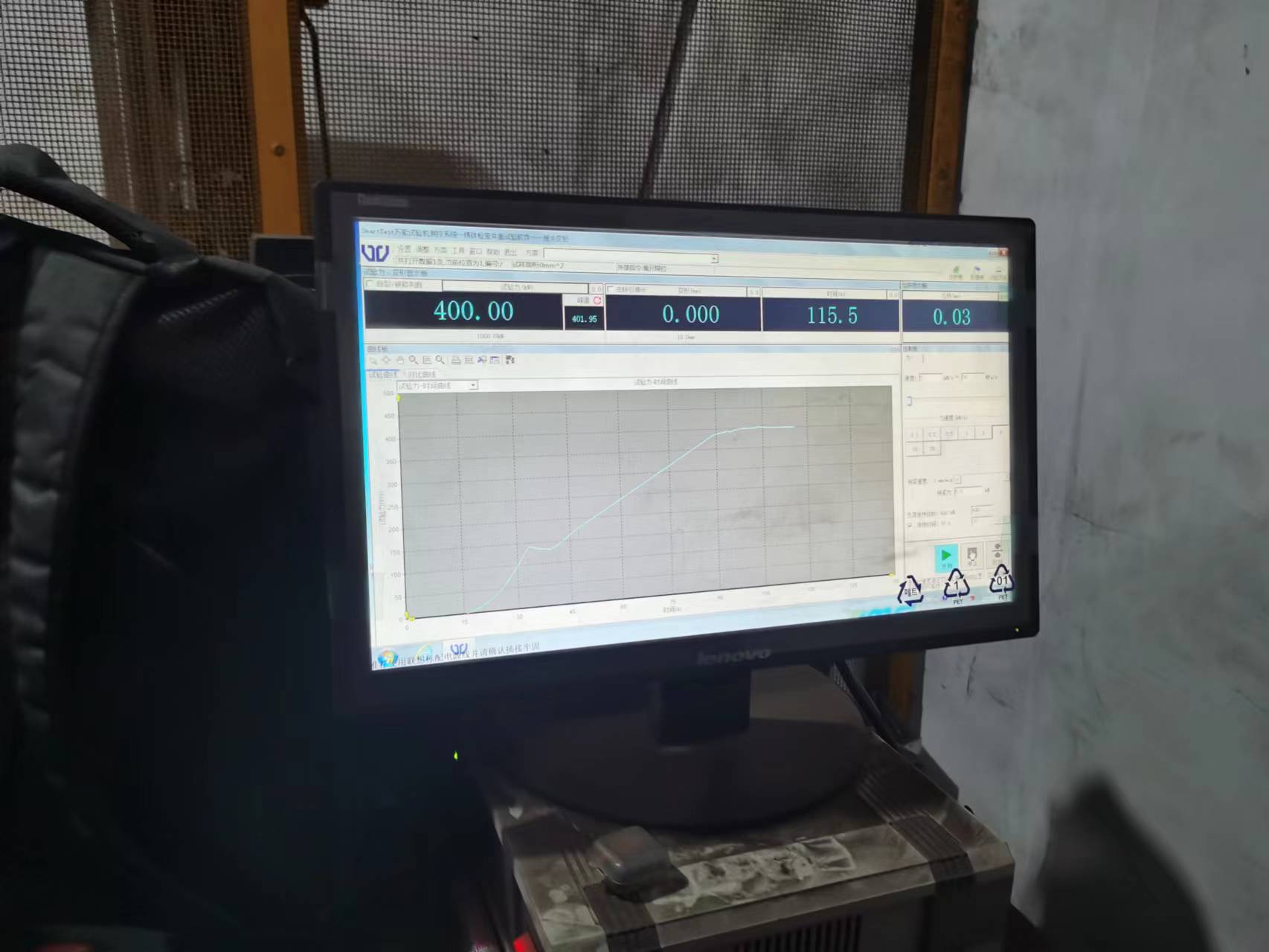

48 butterfly valve

5. Power Generation In power plants, butterfly valves control steam and water flow, contributing to the efficient operation of turbines.

Advantages of Using a 48% Butterfly Valve

The 48% butterfly valve offers several benefits that make it a preferred choice in many applications

- Compact Design Due to their design, butterfly valves are generally more compact than other types of valves, making them ideal for installations with limited space.

- Lightweight Construction These valves are typically lighter than equivalent gate or globe valves, resulting in easier handling and installation.

- Quick Operation With a quarter-turn mechanism, butterfly valves can be opened and closed rapidly, providing efficient control in urgent situations.

- Minimal Pressure Drop The streamlined design of the disc reduces turbulence and pressure loss, allowing for efficient fluid flow.

- Cost-Effective Butterfly valves are generally more economical compared to other valve types, making them a cost-effective option for large-scale applications.

Maintenance Considerations

While butterfly valves are designed to be durable and low-maintenance, regular inspections and maintenance practices are essential to ensure their longevity and performance. Users should check for signs of wear, corrosion, or material degradation. Lubricating the stem assembly and replacing seals when necessary will help maintain the functional integrity of the valve.

Conclusion

The 48% butterfly valve represents a critical component in industrial fluid control systems. Its efficient design, versatility, and minimal maintenance needs make it an invaluable asset across various applications. As industries continue to advance, the demand for reliable and efficient control mechanisms like the butterfly valve will only increase, further underscoring its importance in modern engineering and technology. Whether in water treatment, chemical processing, or HVAC systems, understanding and utilizing the capabilities of the 48% butterfly valve can lead to enhanced operational efficiency and safety.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025