1 4 quick exhaust valve

Understanding the 1% 204% Quick Exhaust Valve Efficiency and Applications

In the realm of pneumatic systems and industrial automation, quick exhaust valves play a pivotal role in enhancing the efficiency and responsiveness of various machinery. Among the numerous designs available, the 1% 204% quick exhaust valve has emerged as a noteworthy model that provides a unique blend of performance and reliability. This article will explore the functionality, advantages, and applications of the 1% 204% quick exhaust valve, shedding light on why it is a popular choice for many industrial applications.

What is a Quick Exhaust Valve?

A quick exhaust valve is a specialized component used in pneumatic systems to improve the operation of actuators such as cylinders. Its primary function is to rapidly discharge air from the cylinder when it is needed, ensuring quicker actuator response times. This is particularly important in applications where speed and precision are critical. The quick exhaust valve is designed to release compressed air much faster than standard exhaust pathways permit, significantly reducing cycle times.

The Mechanics of the 1% 204% Quick Exhaust Valve

The model denoted as the 1% 204% quick exhaust valve refers to specific operational characteristics that define its performance metrics. The 1% typically indicates a quick exhaust ratio, meaning the valve can allow a certain percentage of air to be expelled rapidly compared to the regulated air entering the cylinder. The 204% may refer to certain specifications related to flow capacity, pressure ratings, or other performance metrics that determine how efficiently the valve operates under varying conditions.

This valve operates by utilizing a simple design that contains a piston or diaphragm mechanism, which opens and closes the exhaust port in response to changes in pressure. When the air supply is engaged, the valve allows air into the actuator quickly. Upon the reversal of the pressure, the valve, due to its design, allows for efficient and rapid exhaust of air, drastically shortening the time it takes for an actuator to reset or reverse motion.

Advantages of Using the 1% 204% Quick Exhaust Valve

1. Increased Efficiency The primary advantage of employing the 1% 204% quick exhaust valve is its ability to enhance the efficiency of pneumatic systems. By allowing for faster exhaust times, it leads to reduced cycle times, which can boost productivity in manufacturing processes.

2. Improved Performance When integrated into systems with pneumatic cylinders, this valve can dramatically improve the performance of machines, leading to more precise and controlled movements. Industries that rely on synchronized actions can benefit significantly as the quick exhaust valve minimizes lag during operations.

1 4 quick exhaust valve

3. Cost-Effectiveness Although the initial investment in a quality quick exhaust valve may be higher, the savings generated through reduced cycle times and improved process efficiency can yield substantial long-term savings in operational costs.

4. Versatility The 1% 204% quick exhaust valve can be employed in various applications, making it highly adaptable. From automotive manufacturing lines to packaging systems and robotic applications, it serves multiple industries, making it a valuable component in any engineer’s toolkit.

Applications in Various Industries

The utility of the 1% 204% quick exhaust valve spans across several sectors, including

- Manufacturing In assembly lines where speed is essential, quick exhaust valves ensure that pneumatic actuators operate efficiently, leading to increased throughput.

- Robotics Quick responsiveness is crucial in robotic operations. These valves allow robots to perform quicker movements, enhancing their overall reliability and functionality.

- Food and Beverage In automated packaging setups, these valves help maintain high-speed operations, ensuring products are packaged efficiently without downtime.

- Textile and Woodworking In these industries, quick exhaust valves facilitate fast movements of cutting and sewing machines, ensuring precision and reducing the time taken for operations.

Conclusion

The 1% 204% quick exhaust valve stands out as a fundamental component in the efficiency arsenal of modern pneumatic systems. Its ability to enhance speed, performance, and overall operational effectiveness makes it a crucial asset across various industries. As technology continues to evolve, the demand for efficient and reliable components like the quick exhaust valve is only set to grow, marking a significant trend in industrial automation and machinery performance. Understanding and utilizing the benefits of such valves can unlock new levels of efficiency in production and manufacturing environments.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

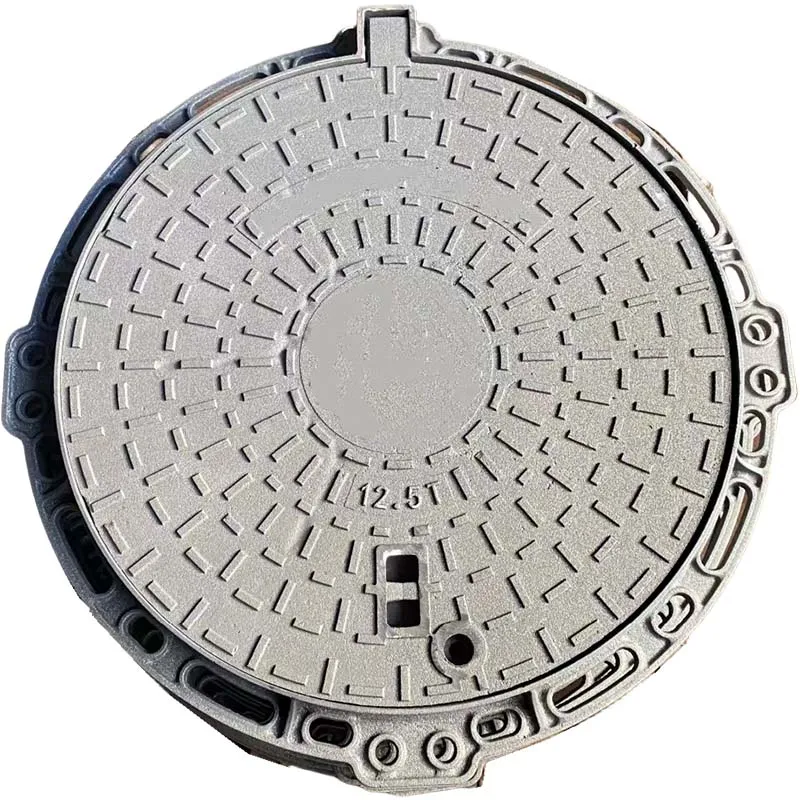

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025